содержание .. 1069 1070 1071 1072 ..

Nissan Tiida C11. Manual - part 1071

ENGINE MAINTENANCE (MR18DE)

MA-41

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

B

MA

N

O

A

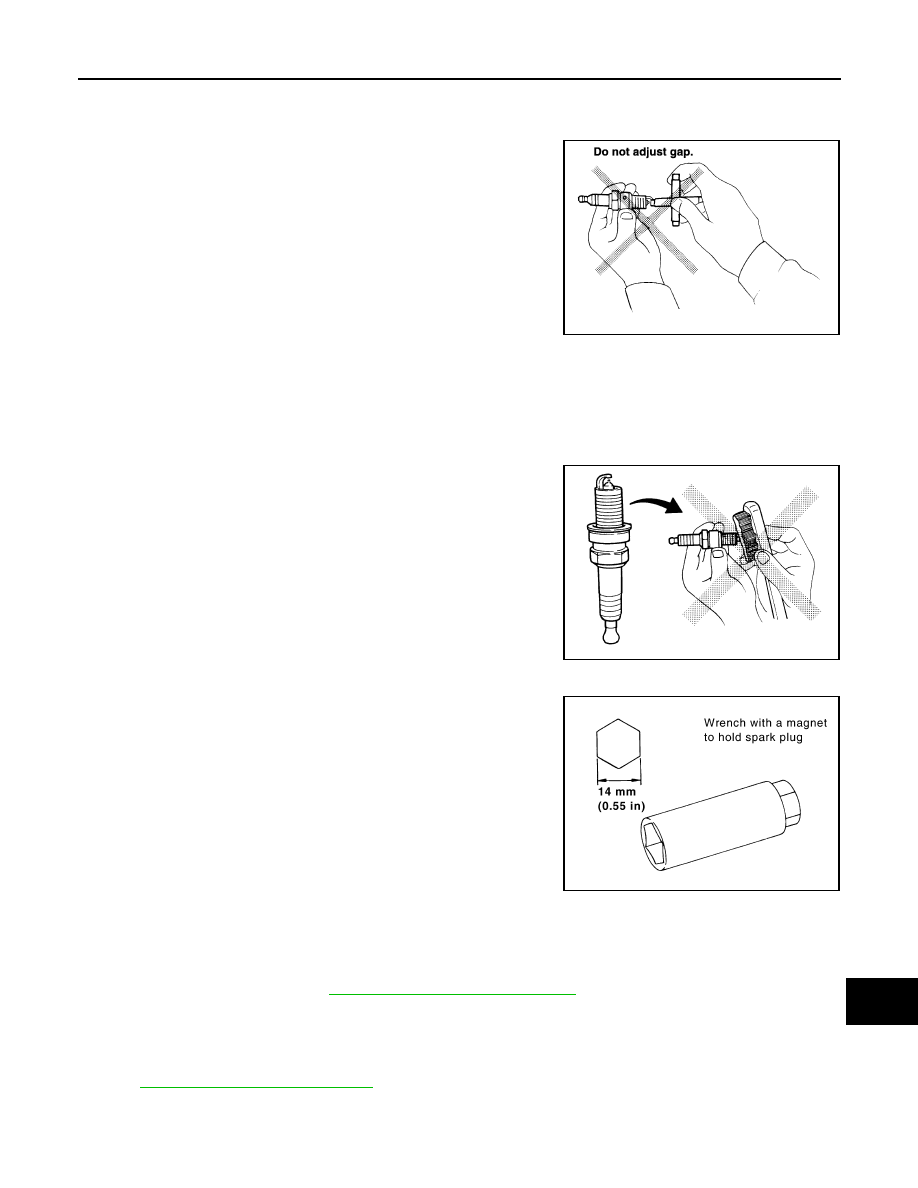

INSPECTION AFTER REMOVAL

CAUTION:

• Never drop or shock spark plug.

• Checking and adjusting spark plug gap is not required

between change intervals.

• If spark plug tip is covered with carbon, a spark plug cleaner may be used.

• Never use wire brush for cleaning spark plug.

INSTALLATION

1.

Install spark plug using suitable tool.

CAUTION:

Never drop or shock it.

2.

Install ignition coil.

CAUTION:

• Handle it carefully and avoid impacts.

• Never disassemble.

3.

Install intake manifold. Refer to

EM-156, "Removal and Installation"

EVAP VAPOR LINES

EVAP VAPOR LINES : Inspection

INFOID:0000000001277636

FL-10, "Removal and Installation"

SMA806CA

Cleaner air pressure

: Less than 588 kPa (5.88 bar, 6 kg/cm

2

, 85 psi)

Cleaning time

: Less than 20 seconds

SMA773C

Plug type

: Platinum tipped

Make

: NGK

Part number

: PLZKAR6A-11

Gap (nominal)

: 1.1 mm (0.043 in)

PBIC3871E