LG936L Wheel Loader. Manual - part 18

Operation & Maintenance Manual──LG936L Wheel Loader

68

z Operating methods

a) Refrigeration

First-time use, turn the air volume and power switch to high gear after the engine started,

turn the temperature control switch to refrigeration. Turn the air volume to obtain low,

middle and high volume of air.

b) Heating

Turn the temperature control switch to the state of off, open the hot water valve the air

volume and power switch, warm air blow constantly. Turn the air volume and power switch

to obtain low middle and high volume of air.

c) Power

indicator

lamp

If the system in a normal energizing the power indicator lamp will come on. If the

refrigeration indicator lamp comes on,

the compressor starts working for the refrigeration of

air conditioning.

Notice:

Avoid the temperature control switch 3 is always in the coolest position and the air volume

and power switch 2 is in the fan low gear (L position), in order to prevent the evaporator

from frosting.

Avoid the sun shining directly in summer.

Please shut the door and window of cab when using the air conditioning; shut the heat source

valve when using for refrigeration; shut the temperature control switch for refrigeration when

using for heating in winner.

Clean the condenser periodically using compress air and cold water, but not using hot water

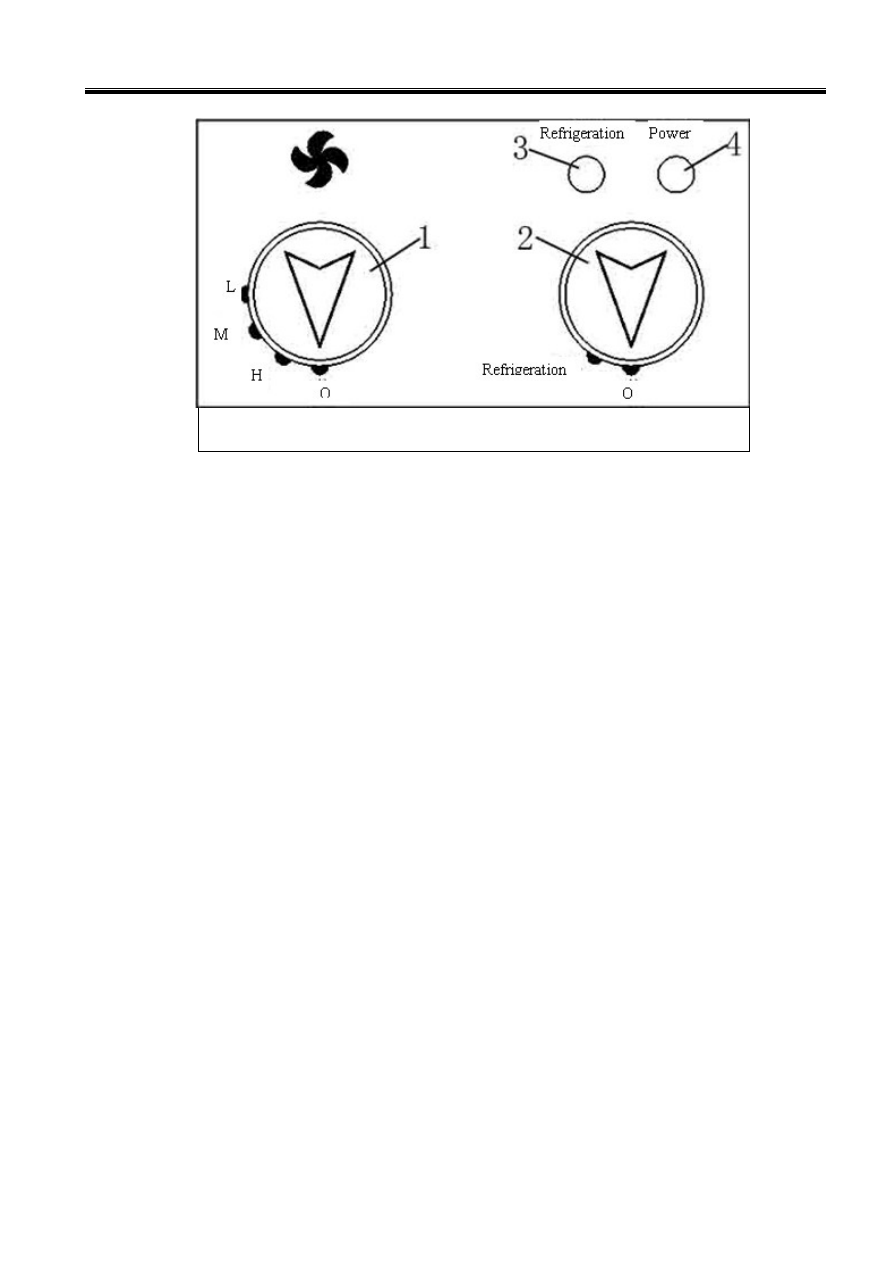

1. Air Volume and Power Switch 2.The Switch to Control The Temperature

3. Refrigeration Indicator Lamp 4. Power Indicator Lamp