Content .. 1023 1024 1025 1026 ..

Mitsubishi Outlander XL. Manual - part 1025

INSPECTION

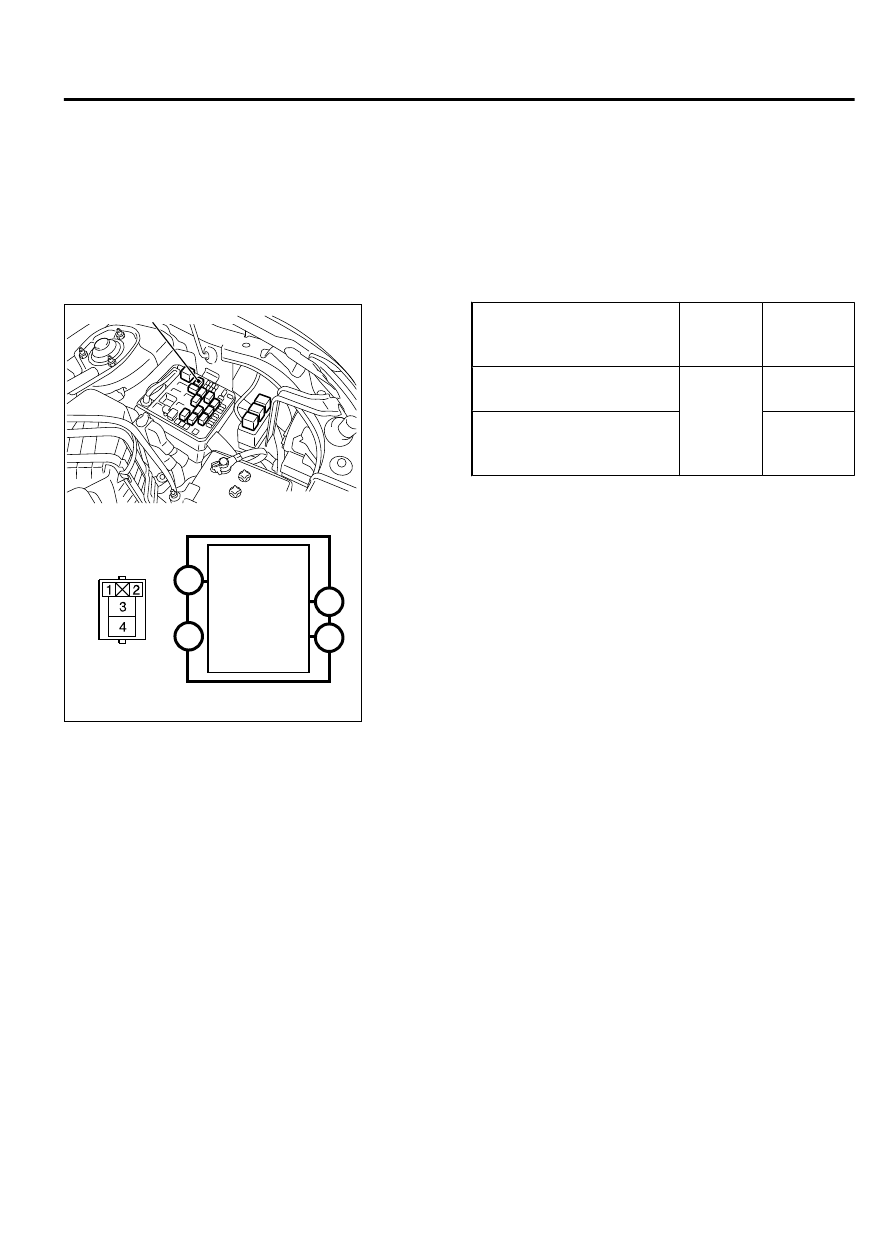

HEADLIGHT RELAY CHECK

M15410900028USA0000010000

HEADLIGHT RELAY (LOW) CHECK

ZC603676

2

3

4

1

0000

Headlight relay (LOW)

Headlight relay

(LOW)

A-28X

FEELD

EFFECT

TRANSISTOR

Battery voltage

Terminal

number

Normal

condition

s

Not energized

3 - 4

No

continuity

With

current

supply

[terminal 4 (+), terminal 1

(-)]

Continuity

exists (2 Ω

or less)

LIGHTING

54Ac-173

HEADLIGHT