Mitsubishi Montero Sport (2004+). Manual - part 589

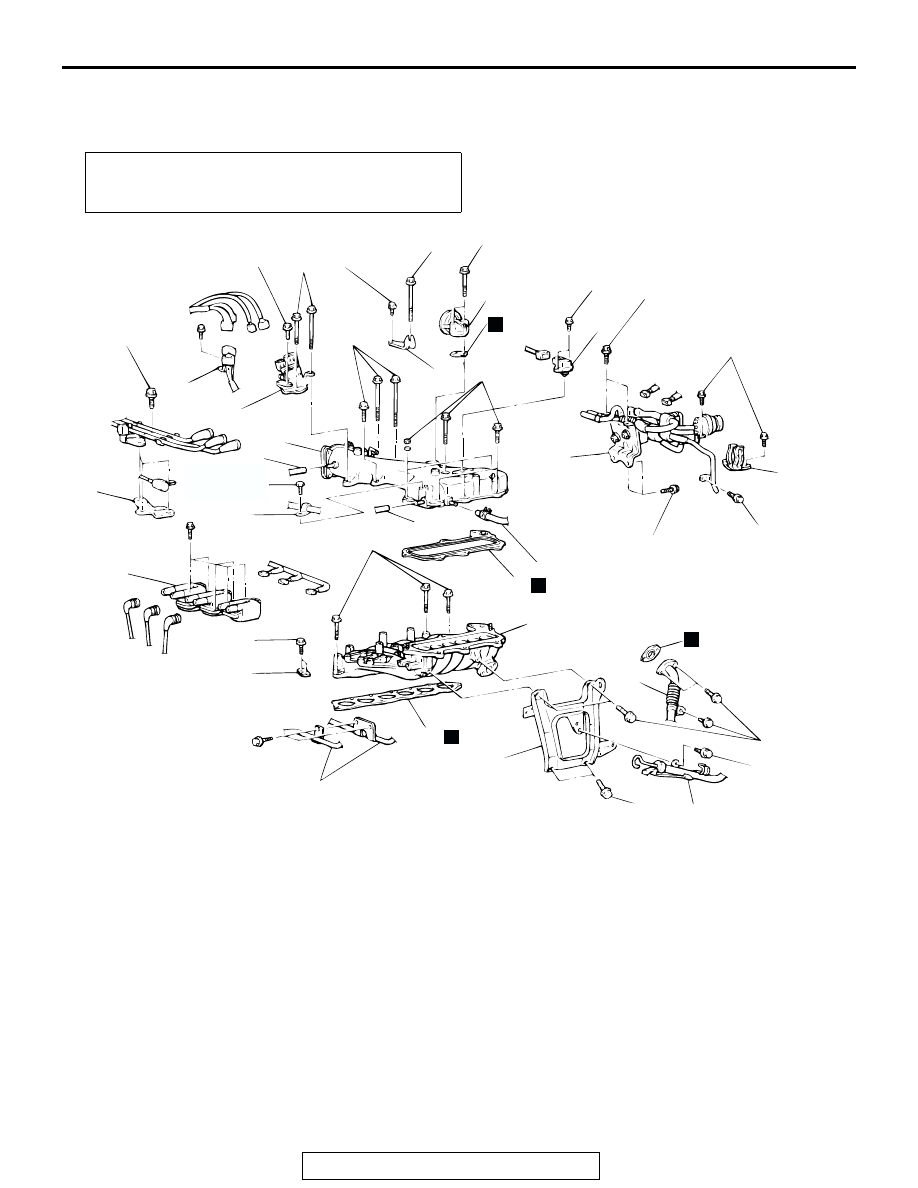

INTAKE MANIFOLD

TSB Revision

INTAKE AND EXHAUST

15-5

INTAKE MANIFOLD

REMOVAL AND INSTALLATION

M1151003000857

Pre-removal and Post-installation Operation

• Throttle Body Removal and Installation (Refer to GROUP

).

AC004649

4.9 N·m

43 in-lb

8.8 N·m

78 in-lb

8.8 N·m

78 in-lb

22 N·m

16 ft-lb

18 N·m

13 ft-lb

10 - 12 N·m

89 - 106 in-lb

10 - 12 N·m

89 - 106 in-lb

17 - 20 N·m

12 - 14 ft-lb

17 - 20 N·m

12 - 14 ft-lb

7

4

5

14

11

12

6

N

10 - 12 N·m

89 - 106 in-lb

18 N·m

13 ft-lb

24 N·m

17 ft-lb

35 N·m

26 ft-lb

24 N·m

18 ft-lb

18 N·m

13 ft-lb

15

16

1

19

9

21

8

10

3

17

22

N

18 N·m

13 ft-lb

18

2

20

N

N

AB

10 - 12 N·m

89 - 106 in-lb

18 N·m

13 ft-lb

18 N·m

13 ft-lb

13

REMOVAL STEPS

1.

IGNITION COILS

2.

BRAKE BOOSTER VACUUM

HOSE CONNECTION

3.

PCV HOSE CONNECTION

4.

CRANKSHAFT POSITION

SENSOR AND CAM POSITION

SENSOR CONNECTOR

5.

ACCELERATOR CABLE

BRACKET

6.

IGNITION POWER TRANSISTOR

7.

WATER OUTLET FITTING

BRACKET

8.

WATER PUMP BRACKET

9.

VACUUM HOSE CONNECTION

10. FUEL PIPE CONNECTION

11. SOLENOID VALVE AND VACUUM

HOSE ASSEMBLY

12. VACUUM CONTROL VALVE

BRACKET

13. MANIFOLD ABSOLUTE

PRESSURE SENSOR

14. EGR VALVE

15. EGR PIPE CONNECTION

16. A/T OIL DIPSTICK ASSEMBLY

17. INTAKE MANIFOLD PLENUM

STAY

REMOVAL STEPS (Continued)