Mitsubishi Montero Sport (2004+). Manual - part 96

STARTING SYSTEM

TSB Revision

ENGINE ELECTRICAL

16-25

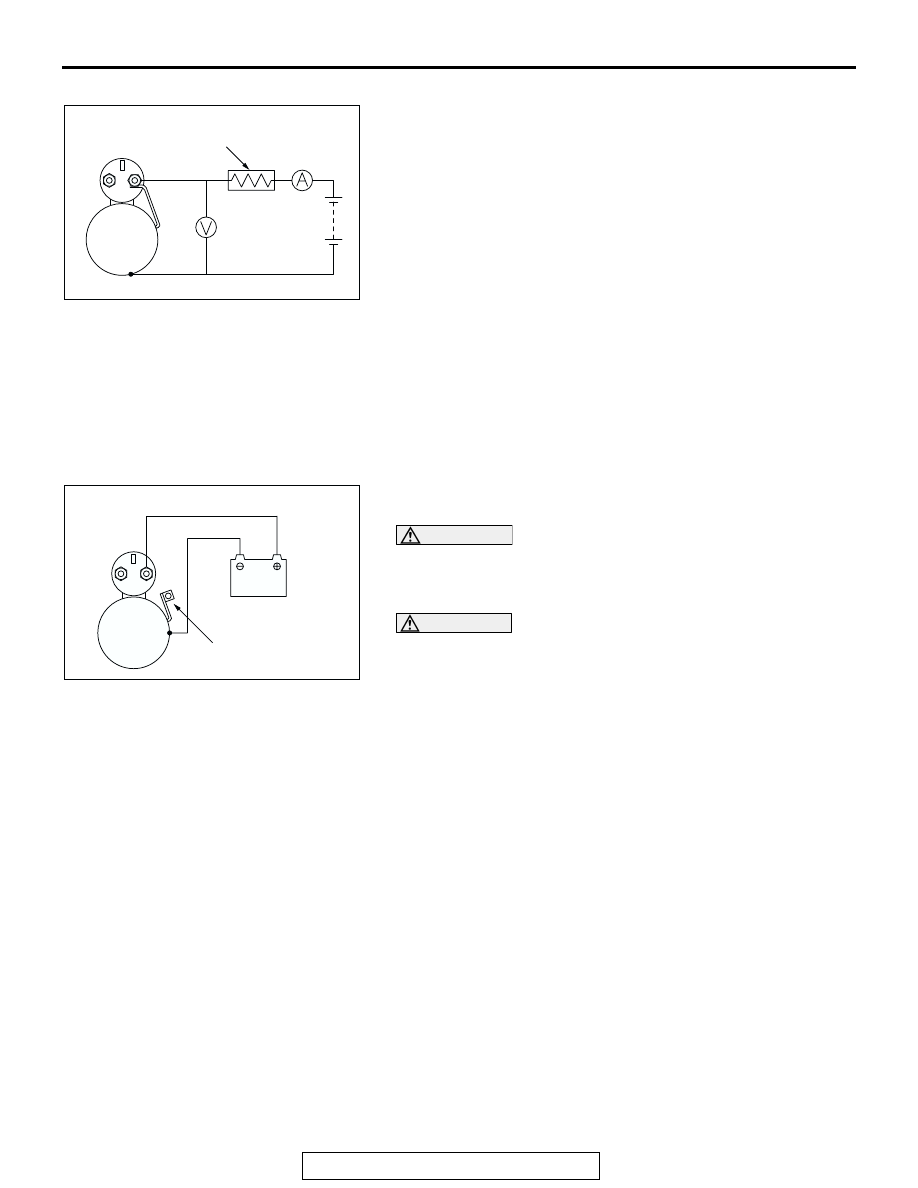

FREE RUNNING TEST

1. Place the starter motor in a vise equipped with soft jaws and

connect a fully-charged 12-volt battery to the starter motor

as follows:

2. Connect a test ammeter (100-ampere scale) and carbon pile

rheostat in series between the positive battery terminal and

starter motor terminal.

3. Connect a voltmeter (15-volt scale) across the starter motor.

4. Rotate carbon pile to full-resistance position.

5. Connect the battery cable from the negative battery terminal

to the starter motor body.

6. Adjust the rheostat until the battery positive voltage shown

by the voltmeter is 11 V.

7. Confirm that the maximum amperage is within the

specifications and that the starter motor turns smoothly and

freely.

Current: maximum 90 Amps

.

MAGNETIC SWITCH RETURN TEST

1. Disconnect the field coil wire from the M-terminal of the

magnetic switch.

CAUTION

This test must be performed quickly (in less than 10 sec-

onds) to prevent the coil from burning.

2. Connect a 12-volt battery between the M-terminal and body.

WARNING

Be careful not to get your fingers caught when pulling

out the pinion.

3. Pull the pinion out and release. If the pinion quickly returns

to its original position, everything is operating properly. If it

doesn't, replace the magnetic switch.

AKX00202

S

B

M

STARTER

MOTOR

BATTERY

AMMETER

VOLTMETER

CARBON-PILE

RHEOSTAT

AB

AKX00203

S

B

M

WIRE

STARTER

MOTOR

BATTERY

AB