Mitsubishi Montero (1991+). Manual - part 328

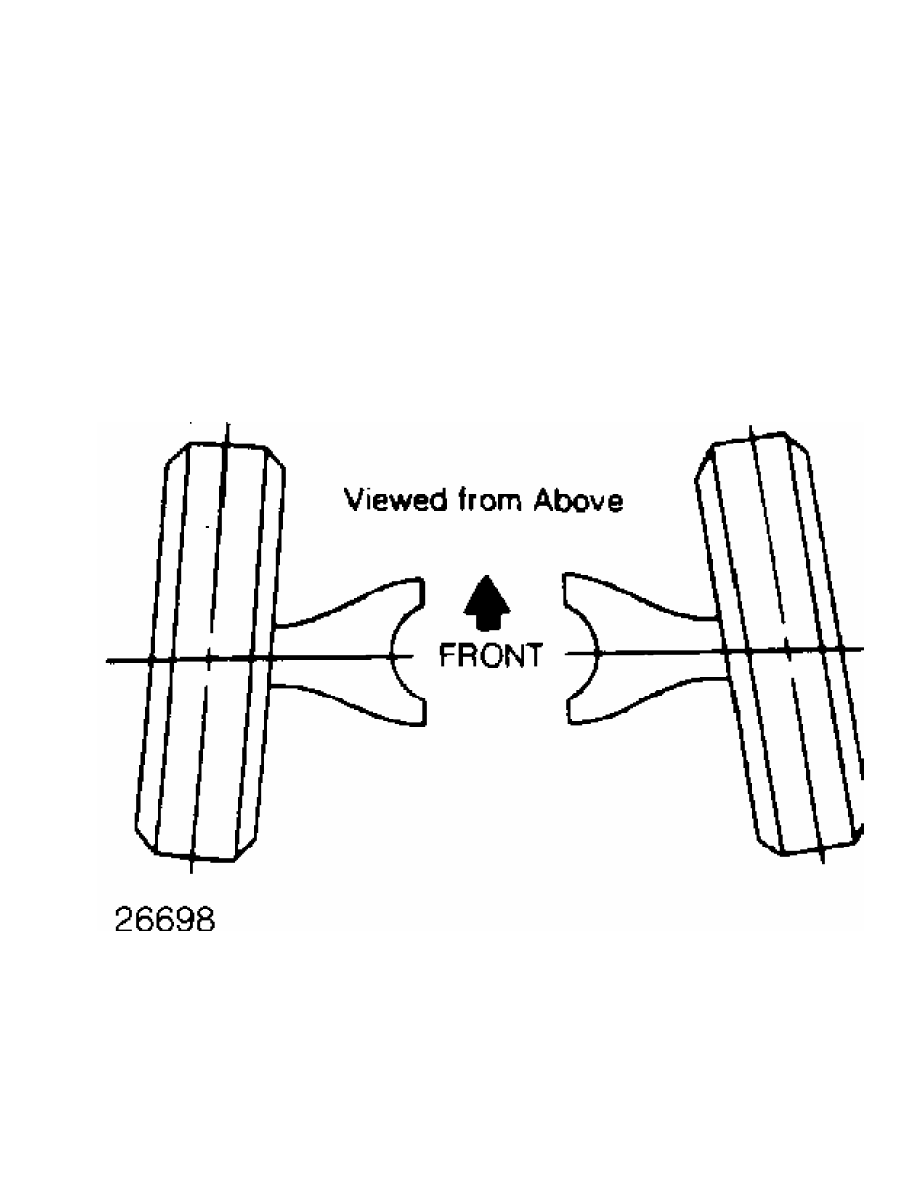

subtracted by the width measured at the front of the tires at about

spindle height. A positive figure would indicate toe-in and a negative

figure would indicate toe-out. If the distance between the front and

rear of the tires is the same, toe measurement would be zero. To

adjust:

1) Measure toe-in with front wheels in straight ahead

position and steering wheel centered. To adjust toe-in, loosen clamps

and turn adjusting sleeve or adjustable end on right and left tie

rods. See Figs. 2 and 5.

2) Turn equally and in opposite directions to maintain

steering wheel in centered position. Face of tie rod end must be

parallel with machined surface of steering rod end to prevent binding.

3) When tightening clamps, make certain that clamp bolts are

positioned so there will be no interference with other parts

throughout the entire travel of linkage.

Fig. 5: Wheel Toe-In (Dimension A Less Dimension B)

TOE-OUT ON TURNS

1) Toe-out on turns (turning radius) is a check for bent or

damaged parts, and not a service adjustment. With caster, camber, and

toe-in properly adjusted, check toe-out with weight of vehicle on

wheels.

2) Use a full floating turntable under each wheel, repeating

test with each wheel positioned for right and left turns. Incorrect

toe-out generally indicates a bent steering arm. Replace arm, if

necessary, and recheck wheel alignment.