Mitsubishi Montero (1991+). Manual - part 18

NOTE: Check compressor refrigerant oil level when replacing seals.

Removal

1) Secure 2 box-end wrenches, to hold armature plate, using

two 6 mm bolts 1 in. (25 mm) or longer. Holding box-end wrenches, use

a socket and ratchet to remove clutch hub nut.

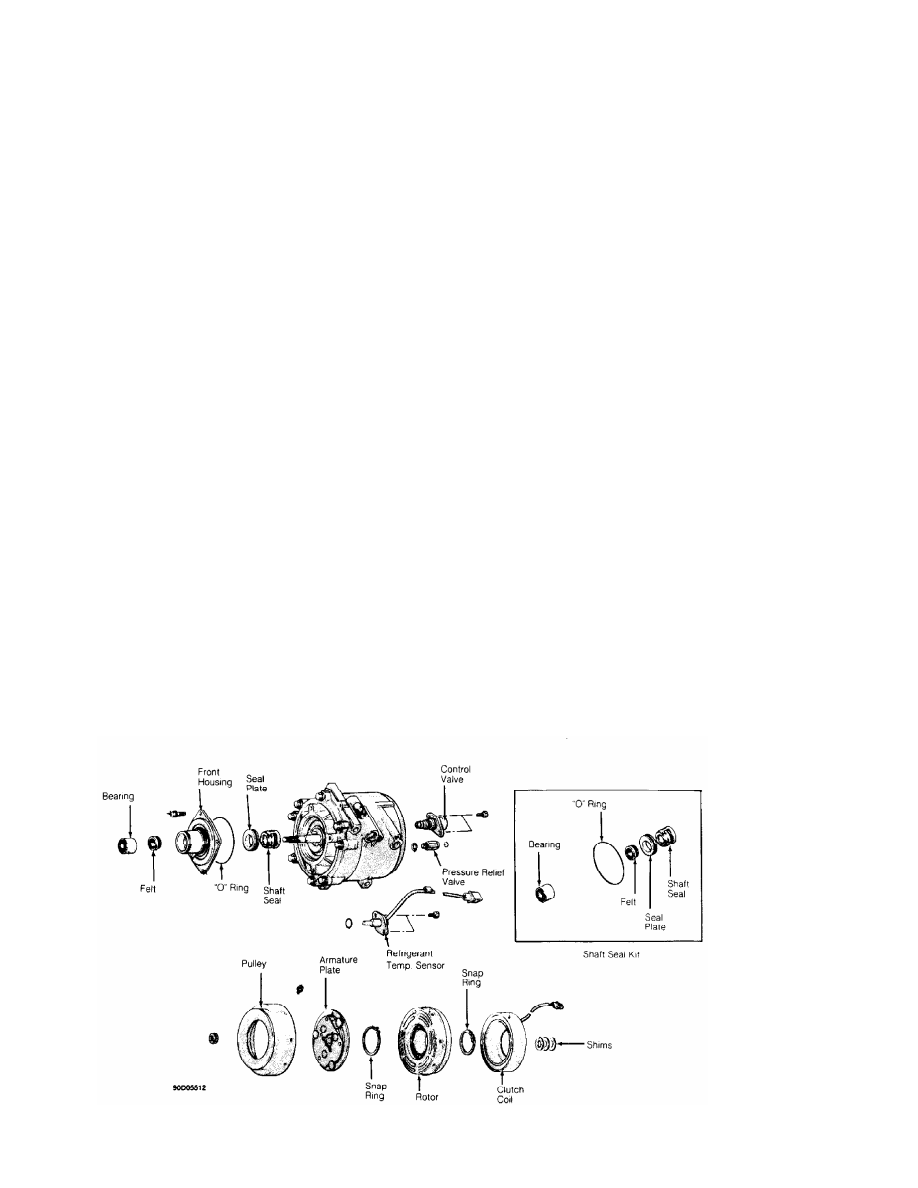

2) Remove armature plate. See Fig. 17. Remove snap ring with

internal snap ring pliers. Remove clutch hub. Remove snap ring and

clutch coil.

3) Remove bolts retaining front housing. Remove front housing

and "O" ring from compressor. Remove shaft seal from shaft. Remove

snap ring from back side of front housing. Remove seal plate.

4) Use brass drift and hammer to lightly tap shaft bearing

from front housing. Remove felt seal.

NOTE: Do not touch the sealing surfaces of the shaft seal carbon

ring and shaft seal plate.

Installation

1) Lubricate shaft seal with compressor oil. Align notches on

shaft seal with notches on crank shaft. Install shaft seal plate on

the front housing. Install front seal housing to compressor.

2) Use Press Tool (MB991301) to install felt into front

housing. Make sure felt metal section faces up. Use Press Tool

(MB991301) to press bearing into front housing.

3) Align and install clutch coil. Install snap ring so that

the tapered surface is facing outward. Install clutch hub. Install

snap ring. Install armature plate, aligning raised area to notch.

4) Secure 2 box-end wrenches, to hold armature plate, using

two 6 mm bolts 1 in. (25 mm) or longer. Holding box-end wrenches, use

a socket and ratchet to tighten clutch hub nut to 12 ft. lbs. (16 N.

m).

5) Use feeler gauge to measure distance between armature and

clutch hub. If gap is not .01-.02" (.25-.51 mm), remove clutch

assembly and add or remove shims accordingly.

Fig. 17: Sanden Scroll Compressor

Courtesy of Chrysler Motors.