Mitsubishi Montero (1991+). Manual - part 3

surfaces. Resurface head if warpage exceeds specification. See

CYLINDER HEAD (SOHC) table under ENGINE SPECIFICATIONS at end of

article. Replace cylinder head if it is not within specification after

resurfacing.

Installation (SOHC)

1) Ensure mating surfaces are clean and dry. Note

identification mark located on front of head gasket. Identification

marks are: "R" for SOHC, "2DN" for DOHC non-turbocharged and "2DT" for

DOHC turbocharged engine. Install head gasket with identification mark

toward timing belt side of engine and facing upward. Ensure all holes

are aligned.

NOTE: Install head gasket with identification mark toward timing

belt side of engine and facing upward. Ensure all holes

align. Install washers on head bolts with chamfered side

toward bolt head.

2) Install cylinder head and bolts. Ensure washers are

installed on head bolts with chamfered side toward bolt head. Using

proper sequence, tighten bolts to specification in 2-3 steps. See

Fig. 5. See appropriate TORQUE SPECIFICATIONS table at end of article.

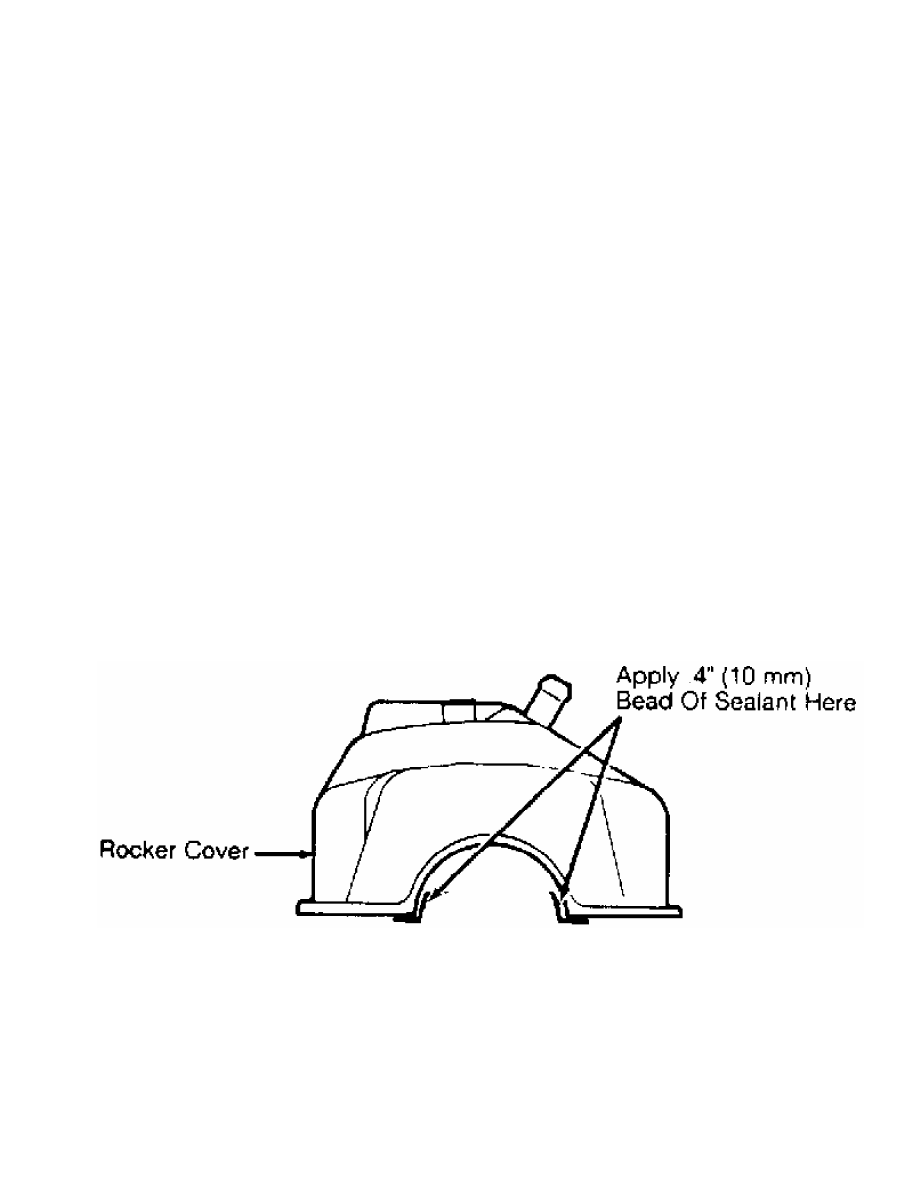

3) Apply sealant to rocker cover sealing surfaces before

installation. See Fig. 6. Ensure rocker cover gasket projections are

aligned with notches in rocker cover. Coat all "O" rings with oil, and

install a new "O" ring on distributor adapter and oil dipstick tube.

4) Coat camshaft area with oil prior to installing

distributor adapter. To complete installation, reverse removal

procedure. Tighten bolts and nuts to specification. See appropriate

TORQUE SPECIFICATIONS table. After engine reaches normal operating

temperature, allow engine to cool, and retighten cylinder head bolts.

Fig. 6: Applying Sealant to Rocker Cover (SOHC)

Courtesy of Mitsubishi Motor Sales of America, Inc.

Removal (DOHC)

1) Drain cooling system. Remove upper and lower intake

manifolds and brackets. See UPPER INTAKE MANIFOLD and LOWER INTAKE

MANIFOLD under REMOVAL & INSTALLATION.

2) Remove turbocharger(s) (if equipped). See TURBOCHARGER

under REMOVAL & INSTALLATION. Remove heat shields from exhaust

manifolds. Remove exhaust manifolds. See EXHAUST MANIFOLDS under

REMOVAL & INSTALLATION.

3) Remove spark plug wires and ignition coils. Remove rocker

cover and gasket. Remove timing belt and timing belt inner covers. See