Mitsubishi Galant (2004+). Manual - part 591

PISTON AND CONNECTING ROD

TSB Revision

ENGINE OVERHAUL <2.4L ENGINE>

11B-53

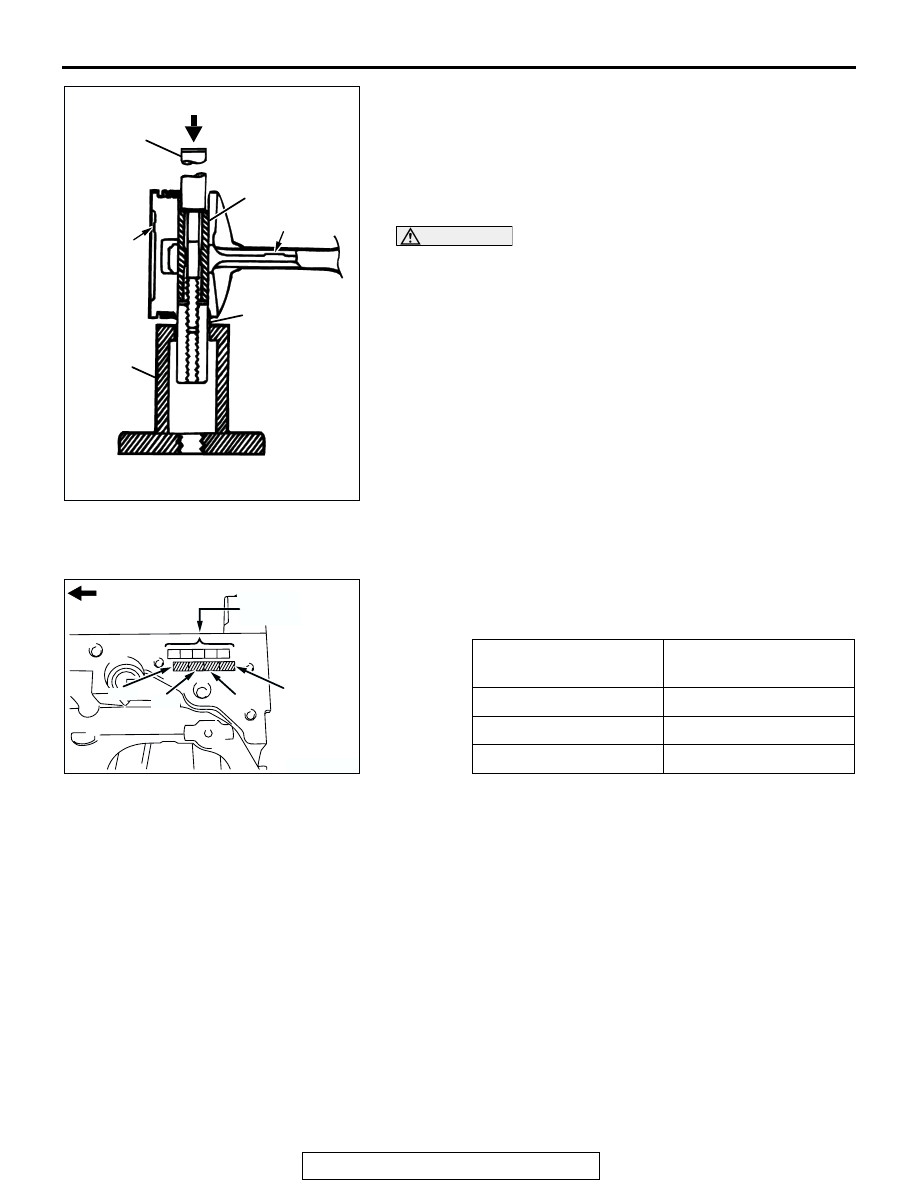

3. Insert the press pin through the piston pin hole. Select the

correct connecting rod guide pin (See above). Thread the

guide pin onto the threaded portion of the press pin.

4. Position the piston assembly on the piston support in the

press. With the press pin up as shown, insert the guide pin

through the hole in the piston and through the hole in the

piston support.

CAUTION

To avoid piston damage, the piston support must seat

squarely against the piston. Verify that the piston pin will

slide through the hole in the piston support.

5. Press the piston pin out of the assembly.

6. Remove the piston pin from the press pin.

INSTALLATION SERVICE POINTS

.

>>A<< PISTON PIN INSTALLATION

1. When replacing the piston, read off the cylinder bore size

mark on the cylinder block as illustrated, and select a piston

according to the following table.

NOTE: The piston size mark shows on the top of the piston.

AK301793

PRESS

PIN

PISTON PIN

FRONT MARK

FRONT

MARK

CONNECTING

ROD GUIDE PIN

BASE

AB

CYLINDER BORE SIZE

MARK

PISTON SIZE MARK

I

A

II

None

III

C

AK301530

No.4

No.3

No.1

No.2

TIMING BELT SIDE

AC

CRANKSHAFT

BORE SIZE MARK