Mitsubishi Galant (2004+). Manual - part 161

TIMING BELT

TSB Revision

ENGINE MECHANICAL <3.8L ENGINE>

11C-51

CAUTION

Do not remove the setting pin from the auto-tensioner.

(4) Install the auto-tensioner to the engine.

.

>>B<< TIMING BELT INSTALLATION

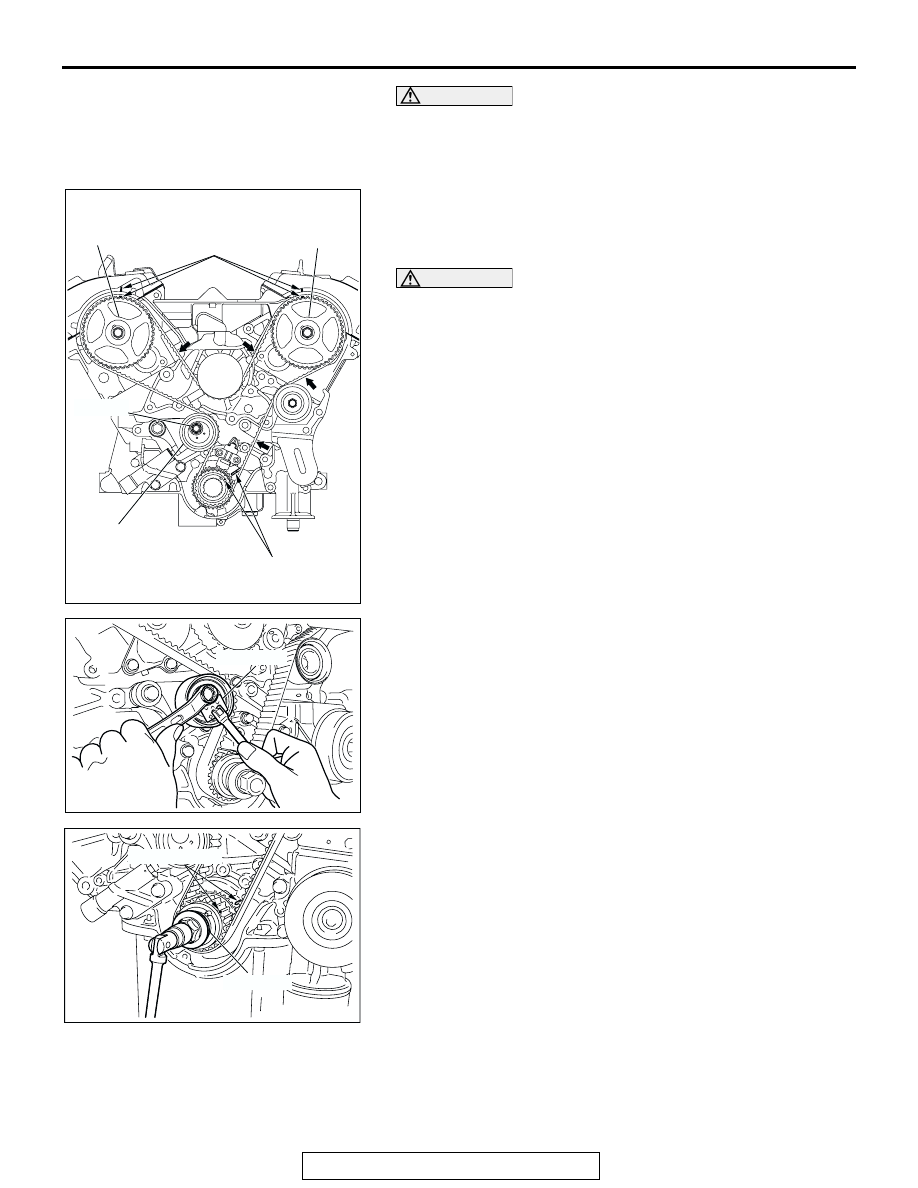

1. Align the timing marks on the camshaft sprockets with those

on the rocker cover and the timing mark on the crankshaft

sprocket with that on the engine block as shown in the

illustration.

CAUTION

The camshaft sprocket (right bank) can turn easily due to

the spring force applied, so be careful not to get your fin-

gers caught.

2. Install the timing belt by the following procedure so that

there is no deflection in the timing belt between each

sprocket and pulley.

(1) Crankshaft sprocket

(2) Idler pulley

(3) Camshaft sprocket (Left bank)

(4) Water pump pulley

(5) Camshaft sprocket (Right bank)

(6) Tensioner pulley

3. Turn the camshaft sprocket (Right bank) counterclockwise

until the tension side of the timing belt is firmly stretched.

Check all the timing marks again.

4. Use special tool MD998767 to push the tensioner pulley into

the timing belt, then temporarily tighten the center bolt.

5. Use special tool MD998769 to turn the crankshaft 1/4 turn

counterclockwise, then turn it again clockwise until the

timing marks are aligned.

AC206490

TIMING MARK

TIMING MARK

CENTER

BOLT

TENSION

PULLEY

CAMSHAFT

SPROCKET

(LEFT BANK)

CAMSHAFT

SPROCKET

(RIGHT BANK)

AC

AC205274AB

MD998767

AC205275

MD998769

TIMING MARK

AB