Mitsubishi Pajero Pinin. Manual - part 159

ENGINE AND EMISSION CONTROL –

Emission Control System

17-5

EMISSION CONTROL SYSTEM

GENERAL INFORMATION

The emission control system consists of the following subsystems:

D

Crankcase emission control system

D

Evaporative emission control system

D

Exhaust emission control system

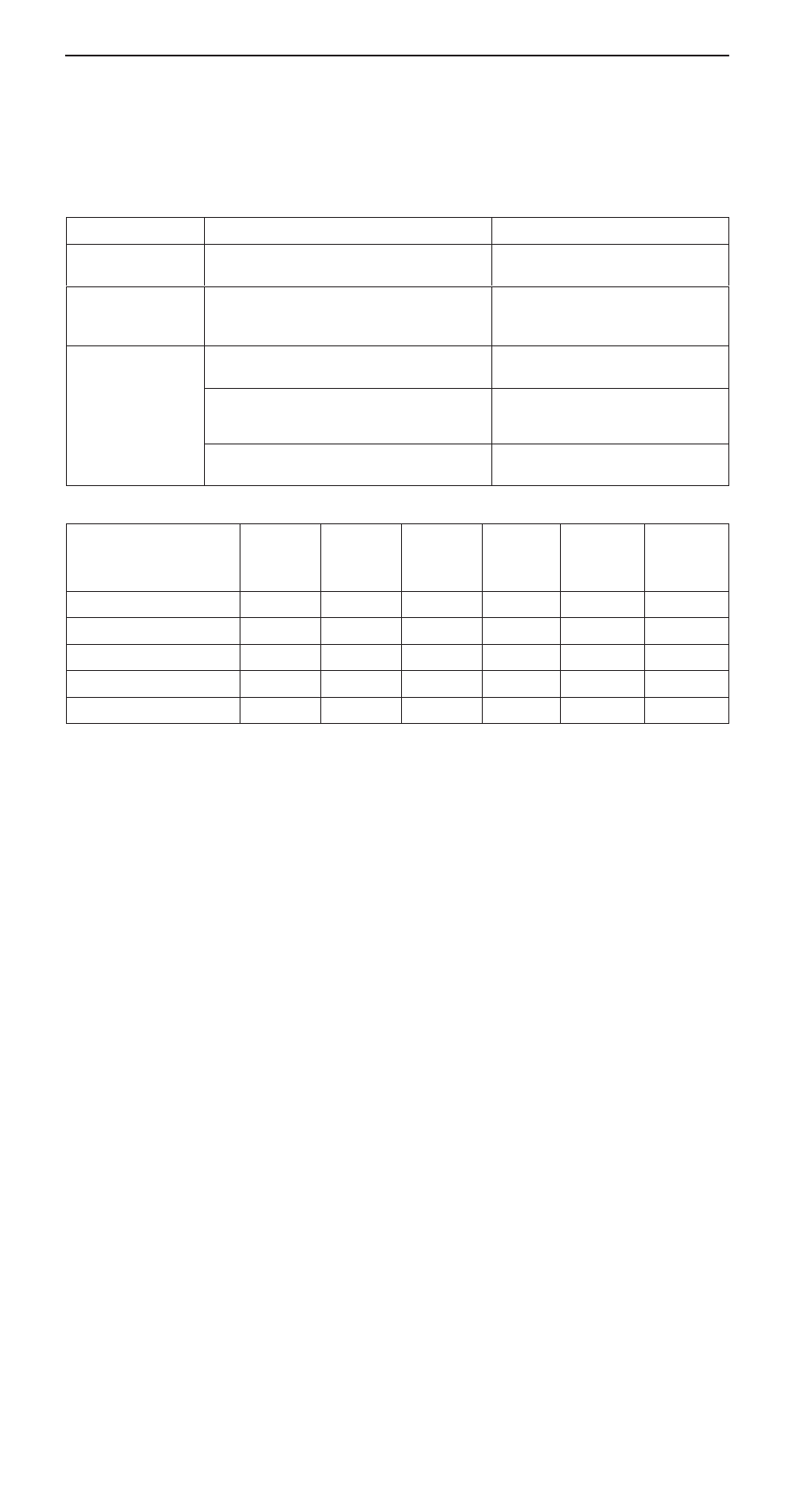

Items

Name

Specification

Crankcase emission

control system

Positive crankcase ventilation (PCV) valve

Variable flow type

(Purpose: HC reduction)

Evaporative emission

control system

Canister

Purge control solenoid valve

Equipped

Duty cycle type solenoid valve

(Purpose: HC reduction)

Exhaust emission

control system

Air-fuel ratio control device–GDI system

Oxygen sensor feedback type

(Purpose: CO, HC, NOx reduction)

Exhaust gas recirculation system

D

EGR valve

Equipped

Stepper motor type

(Purpose: NOx reduction)

Catalytic converter

Monolith type

(Purpose: CO, HC, NOx reduction)

EMISSION CONTROL DEVICE REFERENCE TABLE

Related parts

Crankcase

emission

control

system

Evaporative

emission

control

system

Air/fuel

ratio

control

system

Catalytic

converter

Exhaust gas

recircula-

tion

system

Reference

page

PCV valve

×

17-9

Purge control solenoid valve

×

17-12

GDI system component

×

×

GROUP 13A

Catalytic converter

×

17-17

EGR valve

×

17-14