Mitsubishi Pajero Pinin. Manual - part 53

GDI –

Troubleshooting

13A-78

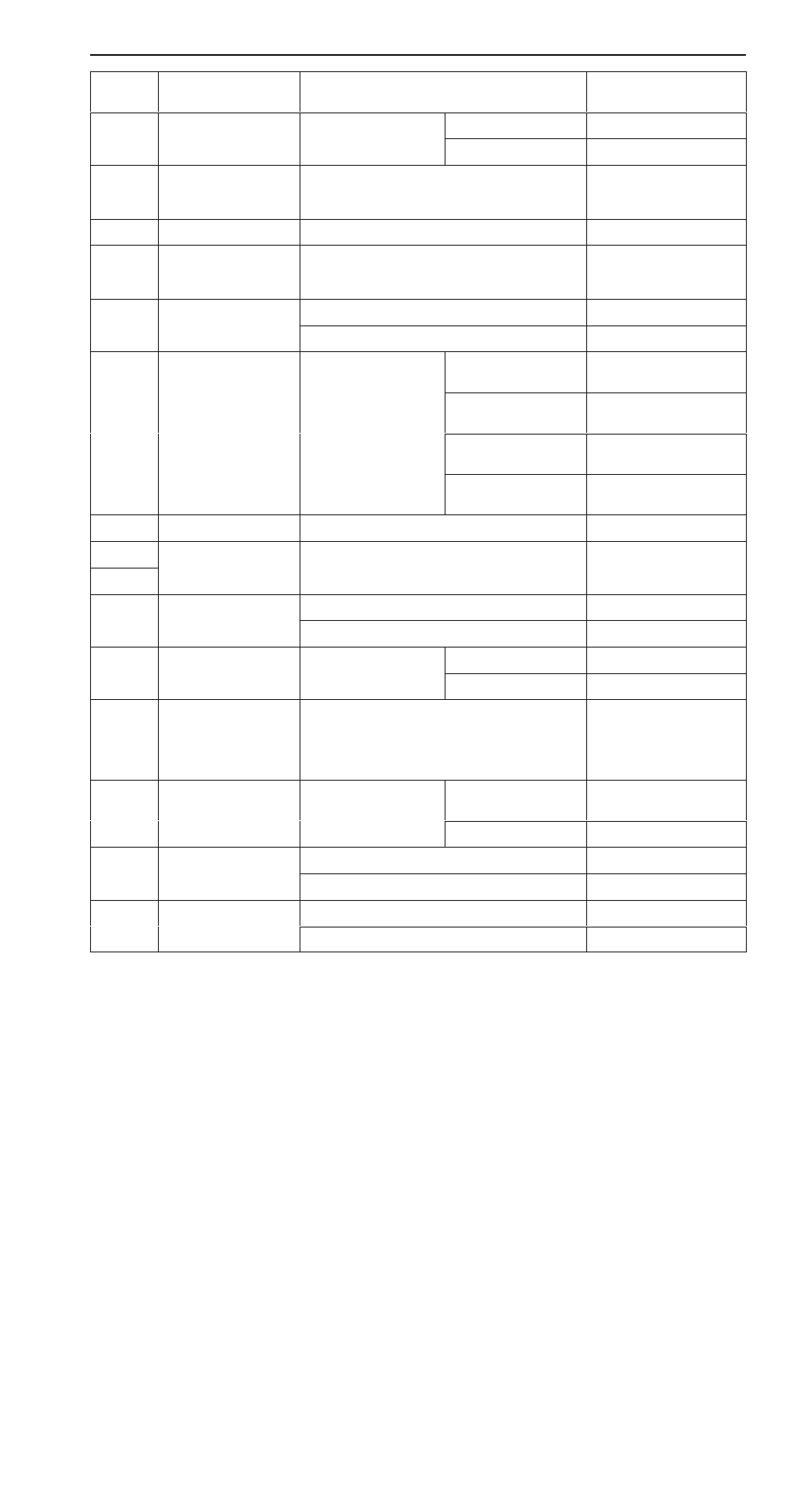

Terminal

No.

Normal condition

Check requirements (engine condition)

Check item

21

Fuel pump relay

Ignition switch: ON

Engine: stopped

System voltage

Engine: Idling

0 – 3 V

31

Engine warning lamp

Ignition switch: OFF

→

ON

0 – 3 V

→

System

voltage (after several

seconds)

41

Sensor power supply

Ignition switch: ON

4.5 – 5.5 V

42

Power supply to

accelerator pedal

position sensor

Ignition switch: ON

4.5 – 5.5 V

43

Crank angle sensor

Engine: Cranking

0.4 – 4.0 V

Engine: Idling

1.5 – 2.5 V

44

Engine coolant

temperature sensor

Ignition switch: ON

Engine coolant

temperature: 0

_

C

3.2 – 3.8 V

Engine coolant

temperature: 20

_

C

2.3 – 2.9 V

Engine coolant

temperature: 40

_

C

1.3 – 1.9 V

Engine coolant

temperature: 80

_

C

0.3 – 0.9 V

45

Tachometer output

Engine: 3,000 r/min

2.0 – 9.0 V

47

Power supply

Ignition switch: ON

System voltage

59

50

Camshaft position

sensor

Engine: Cranking

0.3 – 3.0 V

sensor

Engine: Idling

0.5 – 3.5 V

51

Barometric pressure

sensor

Ignition switch: ON

Altitude: 0 m

3.7 – 4.3 V

sensor

Altitude: 1,200 m

3.2 – 3.8 V

52

Alternator FR terminal

D

Engine: Warm up, and then idling

D

Radiator fan: not operating

D

Headlamp: OFF

→

ON

D

Stop lamp: OFF

→

ON

D

Rear defogger switch: OFF

→

ON

Voltage decrease

54

Power steering fluid

pressure switch

Engine: Warm up, and

then idling

Steering wheel

stationary

System voltage

Steering wheel turning

0 – 3 V

55

Injector driver relay

Ignition switch: OFF

0 – 0.1 V

Ignition switch: ON

0.5 – 1.0 V

56

Throttle valve control

servo relay

Ignition switch: OFF

0 – 0.3 V

servo relay

Ignition switch: ON

0.5 – 1.0 V