Mitsubishi Pajero Pinin. Manual - part 36

GDI –

Troubleshooting

13A-10

TROUBLESHOOTING

DIAGNOSIS TROUBLESHOOTING FLOW

Refer to GROUP 00 – How to Use Troubleshooting/Inspection

Service Points.

NOTE

If the ECU is replaced, the immobilizer-ECU and ignition key

should replaced together with it. Each ECU has an individual

information for immobilizer-ECU, and the individual information

is registered in the immobilizer-ECU.

DIAGNOSIS FUNCTION

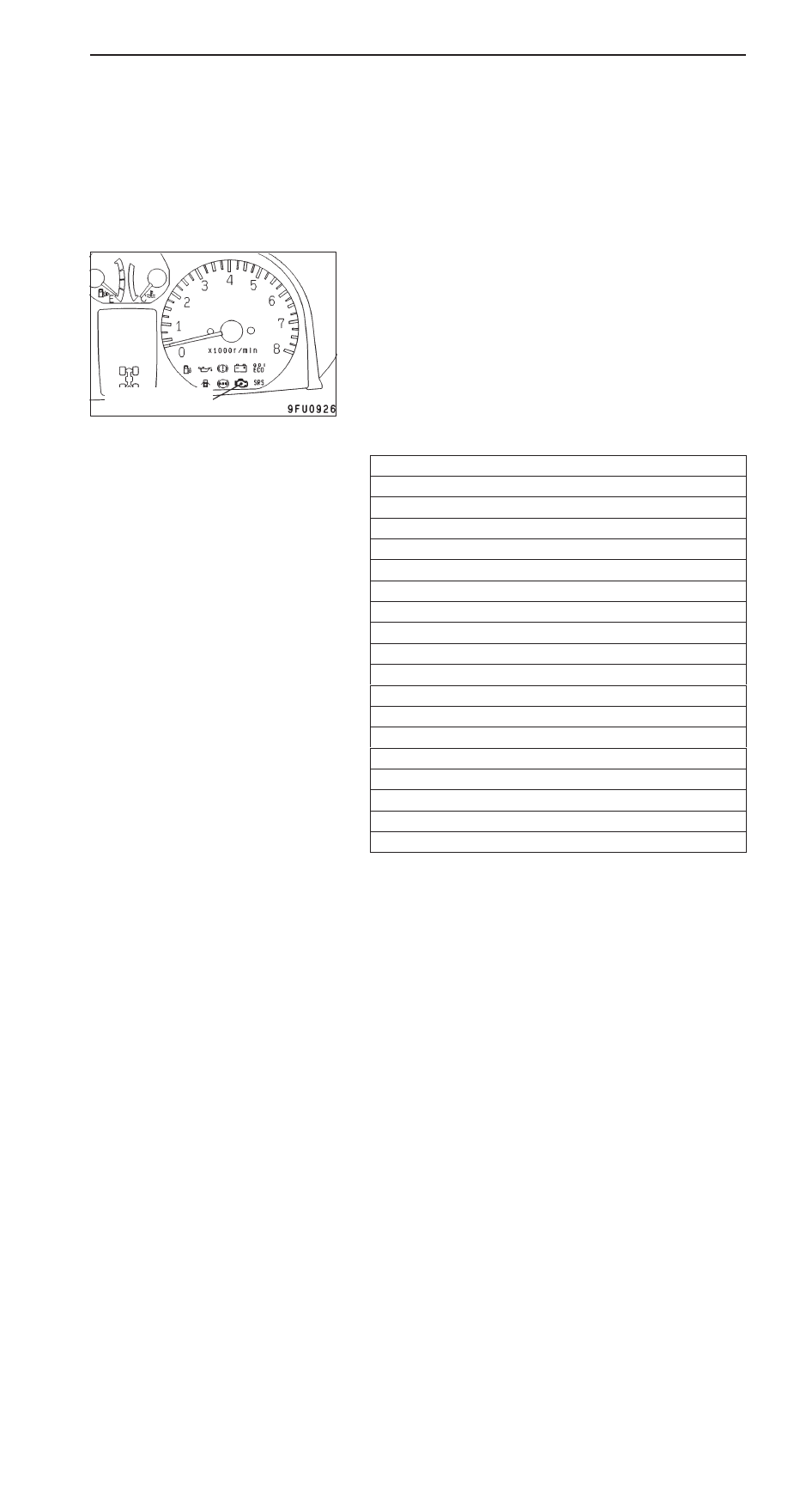

ENGINE WARNING LAMP (CHECK ENGINE LAMP)

If an abnormality occurs in any of the following items related

to the Gasoline Direct Injection (GDI) system, the engine

warning lamp will illuminate.

If the lamp remains illuminated or if the lamp illuminates while

the engine is running, check the diagnosis code output.

Engine warning lamp inspection items

Oxygen sensor

Air flow sensor

Intake air temperature sensor

Throttle position sensor (1st channel)

Throttle position sensor (2nd channel)

Engine coolant temperature sensor

Crank angle sensor

Camshaft position sensor

Barometric pressure sensor

Detonation sensor

Injector

Abnormal combustion

Immobilizer system

Abnormal fuel pressure

Brake vacuum sensor

Fuel system malfunction

Accelerator pedal position sensor (1st channel)

Accelerator pedal position sensor (2nd channel)

Electronic-controlled throttle valve system

Engine warning lamp

(check engine lamp)