Mitsubishi Lancer Evolution 8. Manual - part 99

MANUAL TRANSMISSION - TRANSMISSION

22-21

Checks

M1222001100123

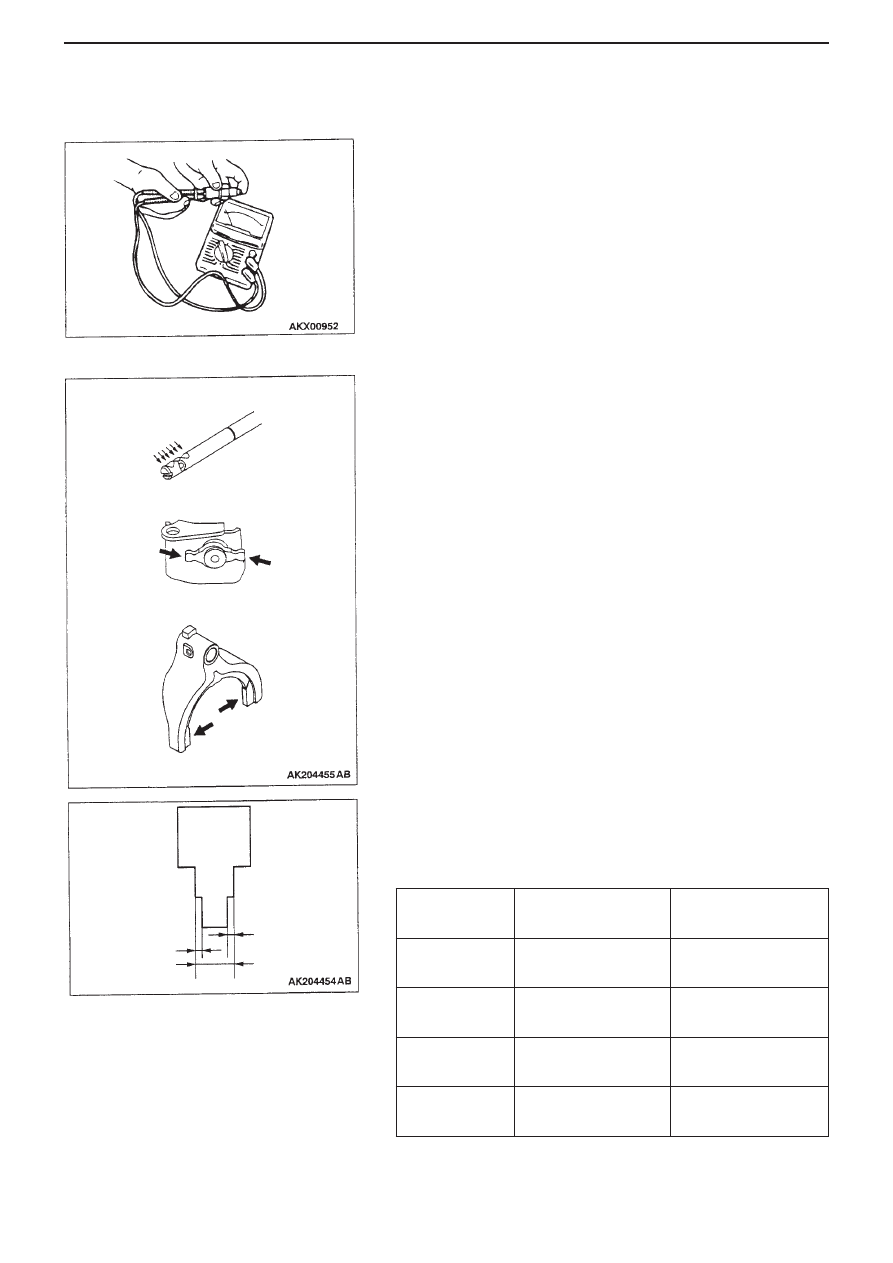

Reversing light switch

1. Check current between terminals.

Item

Live

Press switch

Yes

Release switch

No

2. If there is a fault, check the reversing light switch.

Fork rod / Reverse lever assembly / Shift fork

1. Check for wear, scratches, warping or other

abnormalities on contact and sliding surfaces. If

anything is abnormal replace that part (if the only

problem is extent of contact, replacement is not

necessary).

2. Check width of claws on shift fork (section that

slides against coupling sleeve), make sure it is not

above the limit.

Item

Limit for wear

on 1 side (mm)

Sliding width

when new (mm)

1st-2nd gear

0.2

7.80 to 7.93

3rd-4th gear

0.2

7.80 to 7.93

5th-6th gear

0.2

6.10 to 6.23

Reverse

0.2

12.80 to 12.93

Fork rod

Reverse lever assembly

Shift fork

Sliding width

when new

Wear on one side

Wear on one side