Mitsubishi Eclipse. Manual - part 885

PISTON AND CONNECTING ROD

TSB Revision

ENGINE OVERHAUL <3.0L>

11D-49

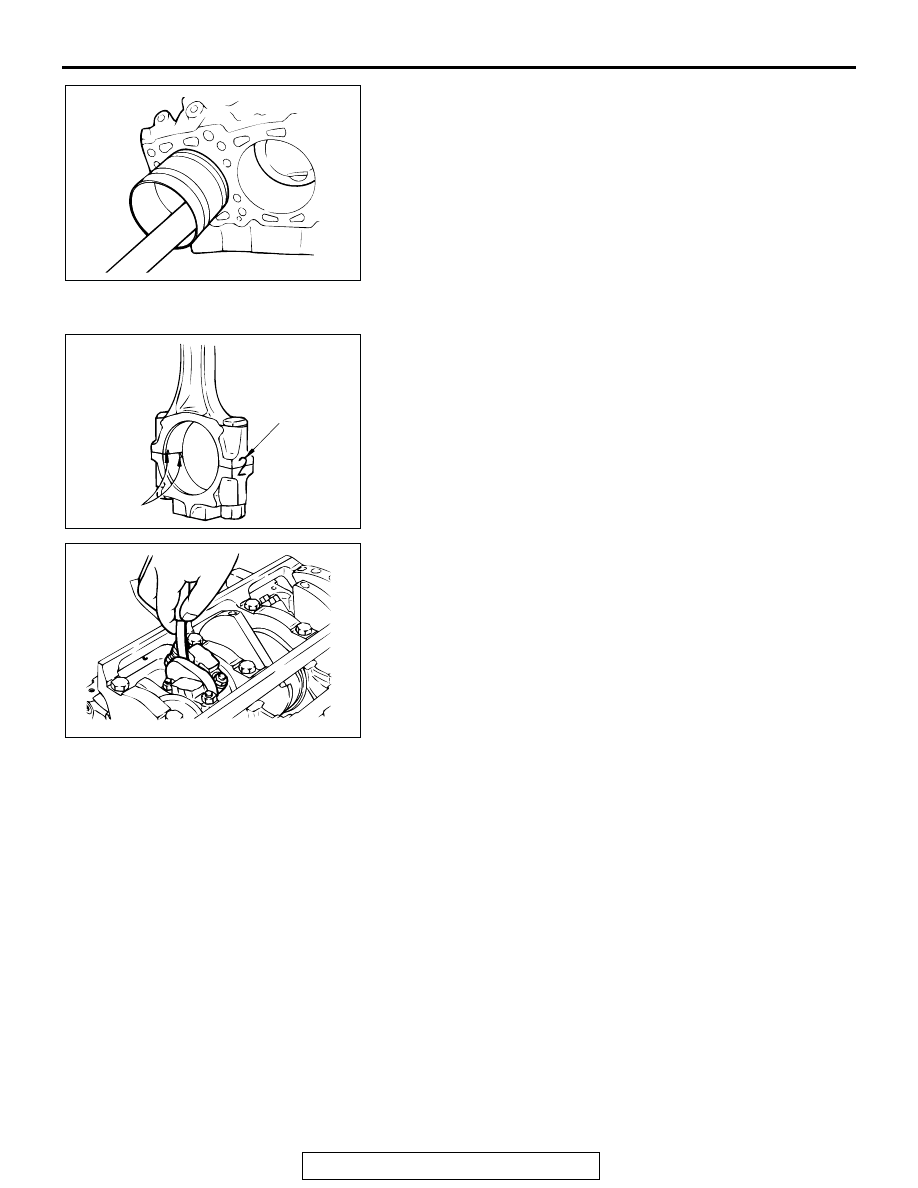

4. Use suitable thread protectors on the connecting rod bolts

before inserting the piston and connecting rod assembly into

the cylinder block.

Care must be taken not to nick the crank pin.

5. Insert the piston and connecting rod assembly into the

cylinder with the front mark on the piston crown pointing to

the timing belt side.

6. Using a suitable piston ring compressor tool, install the

piston and connecting rod assembly into the cylinder block.

.

>>E<< CONNECTING ROD CAP INSTALLATION

1. Mate the correct bearing cap with the correct connecting rod

by checking with the alignment marks marked during

disassembly. If a new connecting rod is used which has no

alignment mark, position the notches for locking the bearing

on the same side.

2. Check if the thrust clearance in the connecting rod big end is

correct.

Standard value: 0.10

− 0.25 mm (0.004 − 0.009 inch)

Limit: 0.4 mm (0.02 inch)

INSPECTION

M1113008500194

.

PISTON

Replace the piston if scratches or seizure is evident on its sur-

faces (especially the thrust surface). Replace the piston if it is

cracked.

.

PISTON PIN

1. Insert the piston pin into the piston pin hole with your thumb.

You should feel a slight resistance. Replace the piston pin if

it can be easily inserted or there is an excessive play.

2. The piston and piston pin must be replaced as an assembly.

.

PISTON RING

1. Check the piston ring for damage, excessive wear, and

breakage. Replace if defects are evident. If the piston has

been replaced, the piston rings must also be replaced.

AKX00721

AKX00735

CYLINDER NO.

NOTCHES

AB

AKX00736