Mitsubishi Eclipse. Manual - part 660

INTAKE MANIFOLD PLENUM

TSB Revision

INTAKE AND EXHAUST

15-11

INSTALLATION SERVICE POINT

.

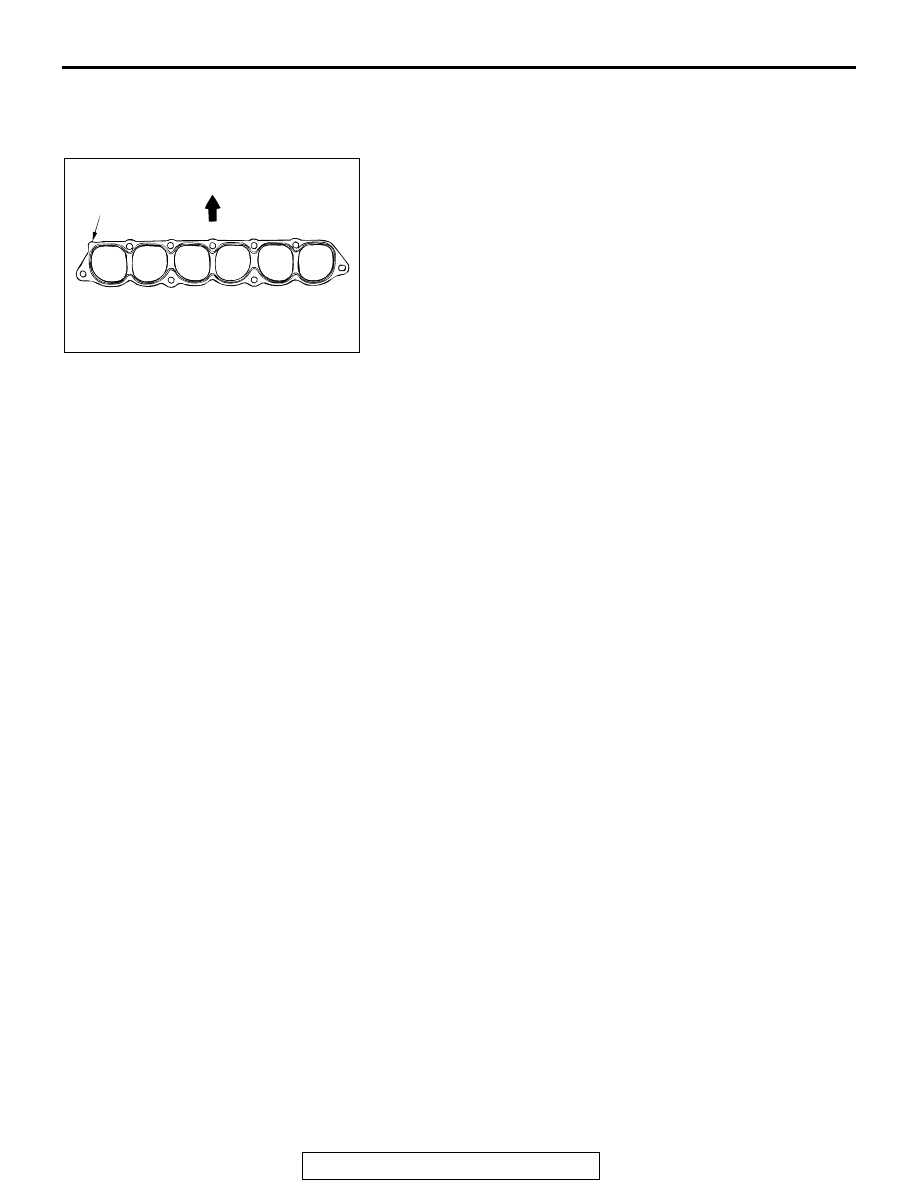

>>A<< INTAKE MANIFOLD PLENUM GASKET INSTALLA-

TION

Install the gasket with the protrusion in the position illustrated.

AC001424

PROTRUSION

FRONT OF

VEHICLE

AB