Mitsubishi Eclipse. Manual - part 110

CYLINDER HEAD GASKET

TSB Revision

ENGINE MECHANICAL <2.4L>

11A-35

Required Special Tool:

• MB991654: Cylinder Head Bolt Wrench (12)

REMOVAL SERVICE POINTS

.

<<A>> POWER STEERING OIL PUMP AND BRACKET

ASSEMBLY REMOVAL

Remove the power steering oil pump and bracket assembly

from the engine with the hose attached.

NOTE: Place the removed power steering oil pump in a place

where it will not be a hindrance when removing and installing

the cylinder head assembly, and secure it with a cord or wire.

.

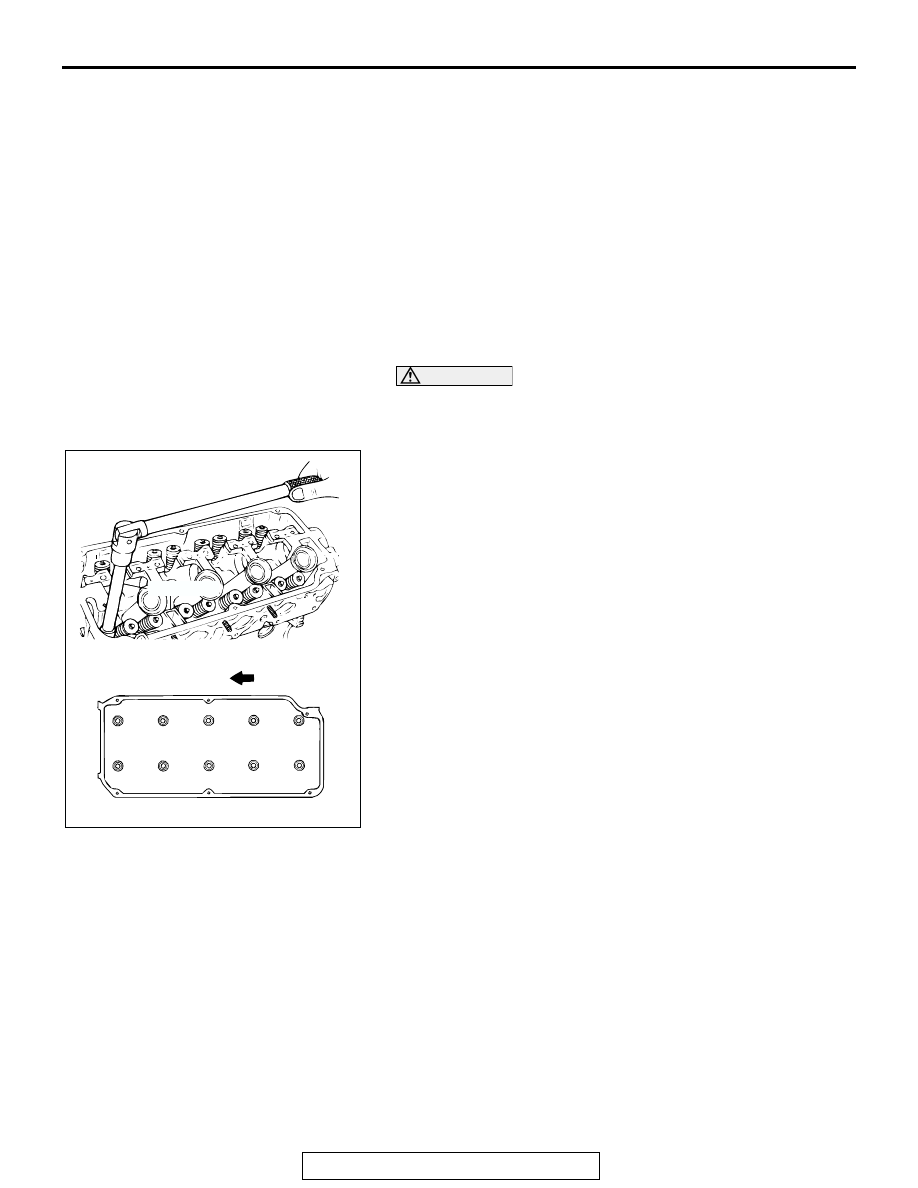

<<B>> CYLINDER HEAD ASSEMBLY REMOVAL

CAUTION

Be careful not to damage or deform the plug guides when

removing the cylinder head bolts. Plug guides cannot be

replaced separately.

Using special tool MB991654, loosen the bolts in two or three

steps in the order of the numbers shown in the illustration, then

remove the cylinder head assembly.

INSTALLATION SERVICE POINTS

.

>>A<< CYLINDER HEAD GASKET INSTALLATION

1. Wipe off all oil and grease from the gasket mounting

surface.

2. Match the shapes of the cylinder head holes with their

respective cylinder head gasket holes.

.

AC000142

INTAKE SIDE

EXHAUST SIDE

FRONT OF

ENGINE

AB

MB991654

1

2

3

5

10

8

7

9

6

4