Mitsubishi Canter (FE, FG). Manual - part 15

60

5 Damage prevention

5.1 Electrical system

MITSUBISHI FUSO body/equipment mounting directives for FE, FG Issue date: 06. 07. 2012

!

Only print out complete sections from the current version

i

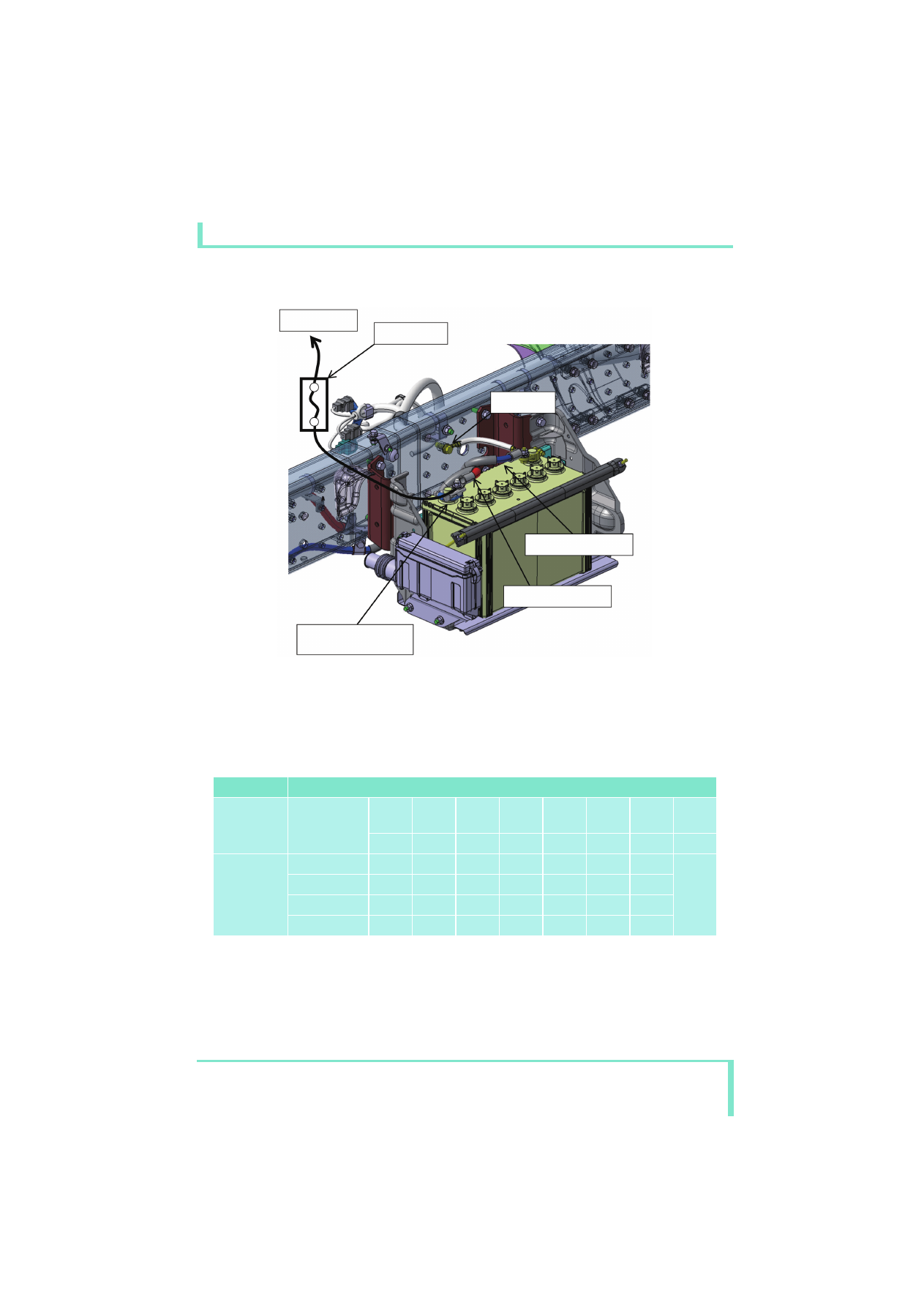

Between battery terminal and fuse

(f) Use a round flat terminal for the power supply terminal and jointly fasten it by using the fixing nut for

attaching the battery cable terminal.

Only one power supply terminal may be used.

Two or more additional terminals can be loosened, resulting in heat being generated or a short.

List of recommended combinations of fuse capacity and wire size

Note: Keep the continuous permissible current within 70 % of the fuse specifications value.

(E.g.) If the fuse used is 10 A:

10 × 0.7 = 7 (A)

R

A load of up to 7 A can be used.

Notes:

1.

҂: Not usable; — : 50 m (165 ft) max

2. AV/AVS wires: general wires; AVX wires: heat-resistant wires

앪 : Usable ҂ : Not usable

Fuse

Wire size [upper] and wire permissible current [lower]

Type

Specifications

0.3

0.012

0.5

0.020

0.85

0.033

1.25

0.049

2.0

0.079

3.0

0.120

5.0

0.200

(mm

2

)

(in.

2

)

11

14

18

23

31

42

57

(A)

Blade and

glass tube

5 A

앪

앪

앪

앪

앪

앪

앪

7.5 A

앪

앪

앪

앪

앪

앪

앪

10 A

҂

앪

앪

앪

앪

앪

앪

15 A

҂

҂

앪

앪

앪

앪

앪

Addition on the

built body

Additional fuse,

etc.

Terminal for taking power

on built body side,

M8 screw

Ground point

Battery cable (-)

Battery cable (+)