Mitsubishi Grandis. Manual - part 406

TOWING AND HOISTING

GENERAL

00-30

Plate type lift

CAUTION

Insert a spacer between the notch and the lift to

avoid damage to the side sill garnish. Be careful

not to contact the spacer against the side sill.

Support the notch with a spacer (100-mm width,

100-mm height and 200-mm depth).

TOWING AND HOISTING

M1001000800421

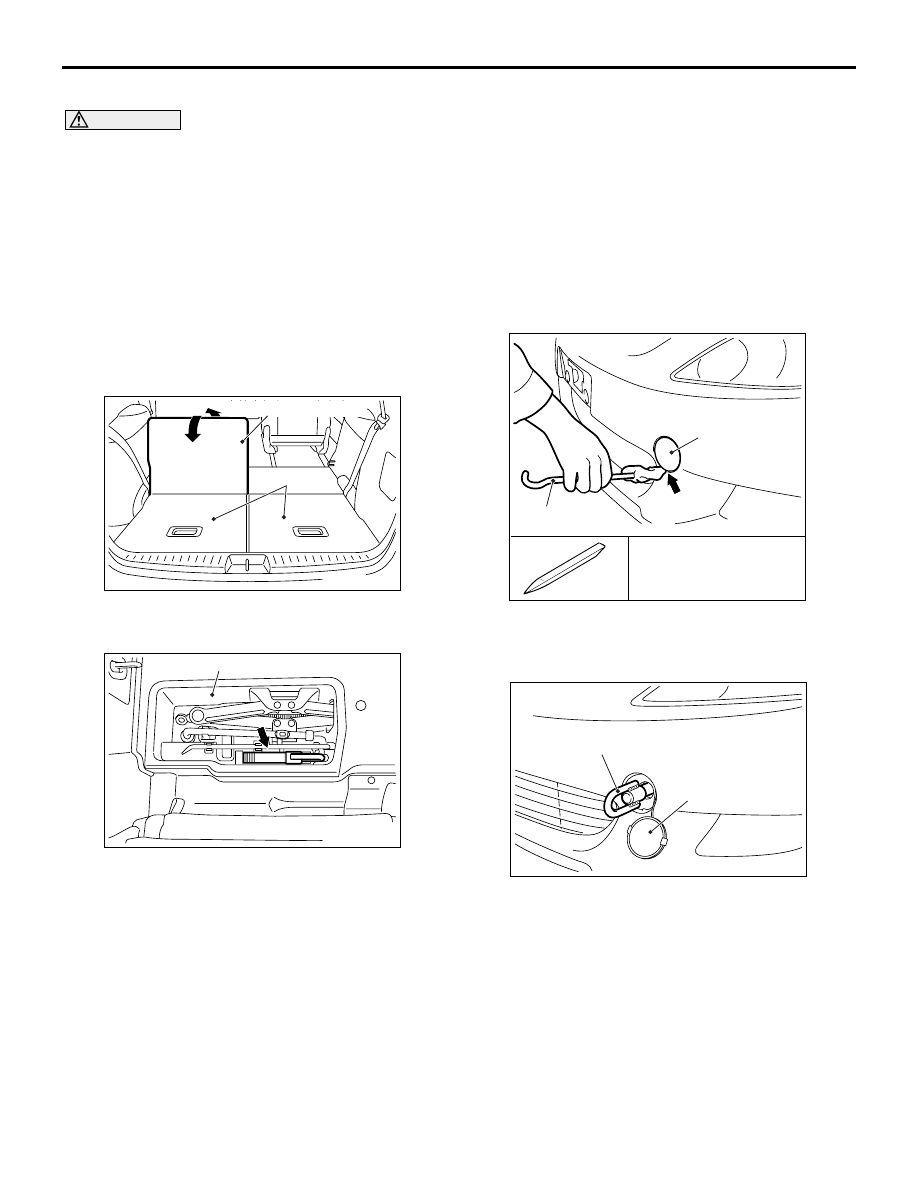

HOW TO SECURE THE TOWING HOOK

When towing this vehicle, attach the towing hook

according to the procedure below.

1. Fold the third seat and open the luggage floor

board.

2. Withdraw the towing hook and jack bar from the

tool box under the luggage floor.

3. Insert special tool MB990784 (Ornament

Remover) or a jack bar as shown, and remove the

towing cover from the front bumper.

4. Secure the towing hook.

STANDARD PART/TIGHTENING-TORQUE TABLE

M1001001100447

Each torque value in the table is a standard value for

tightening under the following conditions.

1. Bolts, nuts and washers are all made of steel and

plated with zinc.

2. The threads and bearing surface of bolts and

nuts are all in dry condition.

The values in the table are not applicable:

1. If toothed washers are inserted.

2. If plastic parts are fastened.

3. If bolts are tightened to plastic or die-cast

inserted nuts.

4. If self-tapping screws or self-locking nuts are

used.

AC302278

Luggage floor board

Third seat

AC

AC302279

AC

Tool box

AC313594

AB

Jack bar

Towing cover

MB990784: Special tool

(Ornament Remover)

AC302281

AC

Towing hook

Towing cover