Mitsubishi L200. Manual - part 415

MASTER CYLINDER ASSEMBLY AND BRAKE BOOSTER ASSEMBLY

BASIC BRAKE

35A-24

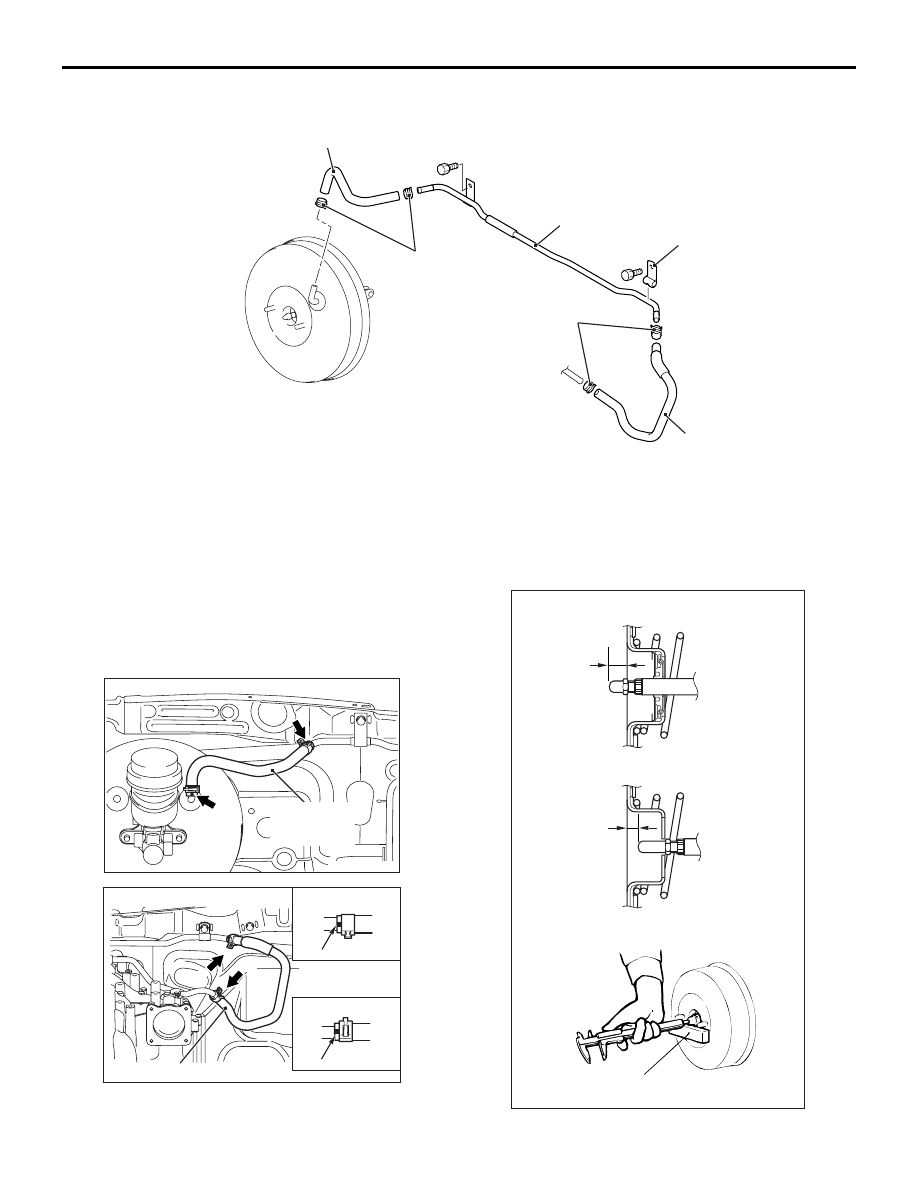

VACUUM HOSE AND VACUUM PIPE

AC805359AB

1

4

3

5

2

6

Removal steps

>>

A

<<

1.

Vacuum hose (with built-in check

valve)

2.

Hose clip

>>

A

<<

3.

Vacuum hose

4.

Hose clip

5.

Vacuum pipe

6.

Clamp

INSTALLATION SERVICE POINTS

>>A<< VACUUM HOSE INSTALLATION

AC502302AC

Vacuum hose

(with built-in

check valve)

AC505445AC

Vacuum hose

B

A

View A

View B

Paint mark

Paint mark

Install the vacuum hose and the clip so that the paint

mark on the vacuum hose and the clip are in the

position shown in the figure.

>>B<< PUSH ROD PROTRUSION AMOUNT

CHECK AND ADJUSTMENT

AC903695AB

A

A

Measuring distance A

<Vehicles without ASTC>

<Vehicles with ASTC>

Block gauge