Mitsubishi L200. Manual - part 381

DRIVESHAFT ASSEMBLY <4WD>

FRONT AXLE

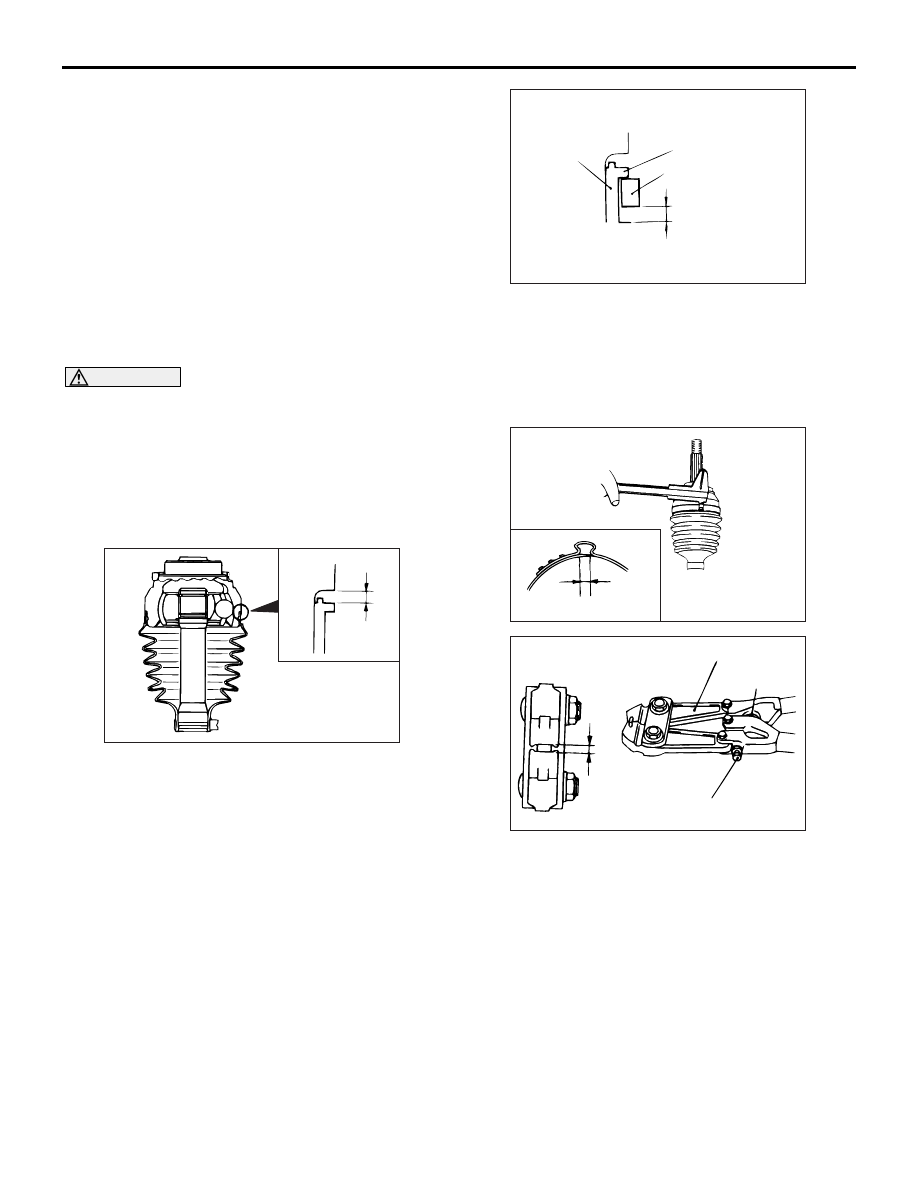

26-29

W = 5.5 mm

− B

Example: If B = 2.9 mm, then W = 2.6 mm.

<If the crimping amount is smaller than 2.4

mm>

Remove the BJ boot band, readjust the value of

(W) in step 3 according to the following for-

mula, and then repeat the operations in

steps 4 and 5 using a new BJ boot band.

W = 5.5 mm

− B

Example: If B = 2.3 mm then W = 3.2 mm.

7. Check that the BJ boot band is not protruding past

the place where it has been installed. If so,

remove it and then repeat the operations in steps

4 to 6 using a new BJ boot band.

CAUTION

The driveshaft joint uses special grease. Do not

mix old and new grease or different types of

grease.

8. Fill the inside of the BJ boot with the specified

amount of the specified grease.

Specified grease: Repair kit grease 120

± 10

g

AC001176

C

AB

9. Install the BJ boot band (large) so that there is the

clearance (C) between it and the BJ housing is at

the standard value.

Standard value (C): 0.05

− 1.55 mm

10.Follow the same procedure as in step 3 to adjust

the size of the opening (W) shown on special tool

MB991561 so that it is at the standard value.

Standard value (W): 3.2 mm

AC001177

D

Projection

BJ boot band

BJ boot

AB

11.Place the BJ boot band (large) against the

projection at the edge of the boot, and then

secure it so that there is a clearance left as shown

by (D) in the illustration.

12.Use special tool MB991561 to crimp the BJ boot

band (large) in the same way as in step 5.

AC004720

E

AB

ACX00993AB

(W)

MB991561

Stopper

Adjusting bolt

13.Check that the crimping amount (E) of the BJ boot

band is at the standard value.

Standard value (E): 2.4

− 2.8 mm

<If the crimping amount is larger than 2.8 mm>

Readjust the value of (W) in step 10 according

to the following formula, and then repeat the

operation in step 12.

W = 5.8 mm

− E

Example: If E = 2.9 mm, then W = 2.9 mm.

<If the crimping amount is smaller than 2.4

mm>

Remove the BJ boot band, readjust the value of

(W) in step 10 according to the following for-

mula, and then repeat the operating in steps

11 and 12 using a new BJ boot band.