Mitsubishi L200. Manual - part 378

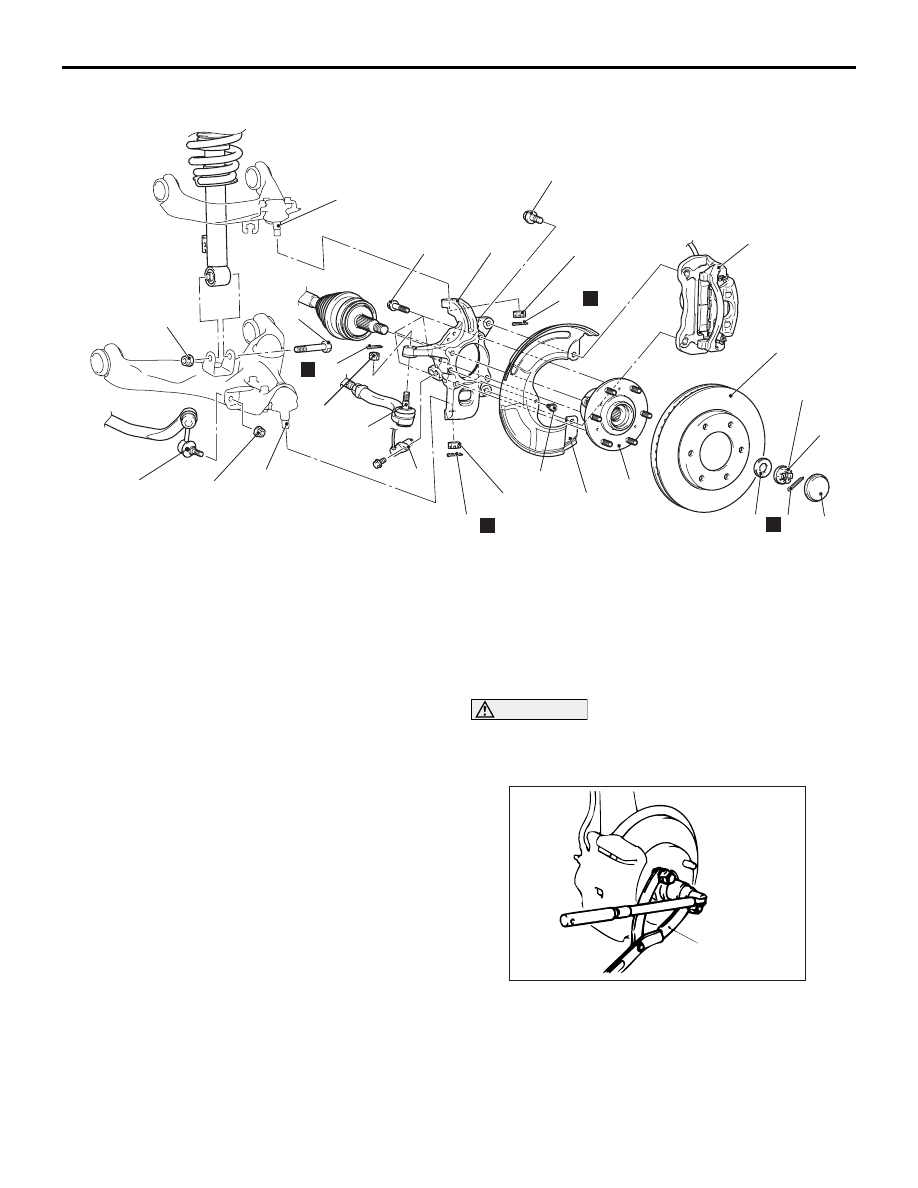

FRONT AXLE HUB ASSEMBLY

FRONT AXLE

26-17

<4WD>

AC500386

AC500367

N

N

N

5

4

3

1

8

9

2

7

6

74 ± 14 N·m

113 ± 9 N·m

147 ± 29 N·m

190 - 210 N·m

40 ± 4 N·m

AE

14

108 ± 10 N·m

12

11

10

16

N

13

15

9 ± 2 N·m

88 ± 10 N·m

17

18

105 ± 10 N·m*

Removal steps

1. Front wheel speed sensor <Vehicles

with ABS>

<<

A

>>

2. Caliper assembly

3. Brake disc

4. Hub cap

5. Split pin

<<

B

>> >>

A

<< 6. Driveshaft nut

>>

A

<< 7. Washer

8. Stabilizer link assembly to lower arm

connection

9. Shock absorber mounting bolt

10. Split pin

<<

C

>>

11. Tie rod end connection

12. Split pin

<<

C

>>

13. Lower arm ball joint connection

14. Split pin

<<

C

>>

15. Upper arm ball joint connection

16. Dust cover

17. Front hub assembly

<<D>>

18. Knuckle

REMOVAL SERVICE POINTS

<<A>> CALIPER ASSEMBLY REMOVAL

1. Remove the caliper assembly with brake hose.

2. Secure the removed caliper assembly with a wire

or other similar material at a position where it will

not interfere with the removal and installation of

the hub assembly and knuckle.

<<B>> FRONT HUB NUT/DRIVESHAFT NUT

REMOVAL

CAUTION

Do not apply pressure to wheel bearing by the

vehicle weight to avoid possible damage when

driveshaft nut is loosened.

AC102462

AC

MB990767

Use special tool front hub and flange yoke holder

(MB990767) to fix the hub and remove the front hub

nut or driveshaft nut.