Mitsubishi L200. Manual - part 194

TROUBLESHOOTING

DIESEL FUEL

13A-572

NOTE: *1: This item is indicated as follows. FF: Initial condition, 0: Non-learning state, 1: Temporary learning

completed status, 2: Learning completed status, 3: Non-learning state.

NOTE: *2: The deterioration level does not request that the battery must be replaced soon.

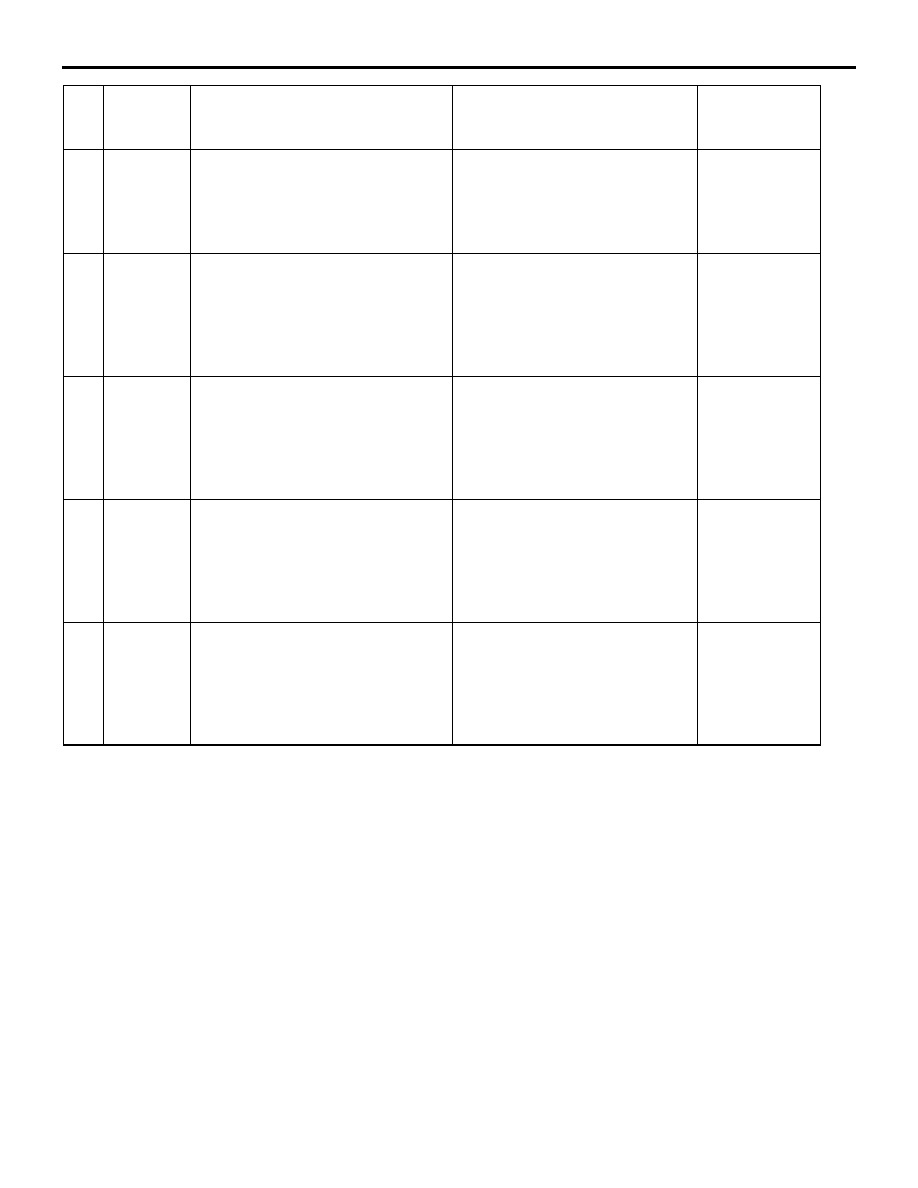

488 Brake

override

operated

odometer

<Euro5>

Shows the driving distance when

the engine-ECU activates the

previous brake override control.

Ignition switch: ON

0

− 1,999,999

km

489 Fuel

torque

target

Indicates the final target torque

• Engine: After warm-up, idle

operation

• Lights and all accessories:

OFF

• Transmission: Neutral <M/T>

or P range <A/T>

0

− 60 Nm

490 Fuel

injection

quantity

pilot 1

Indicates the pilot injection

quantity

• Engine: After warm-up, idle

operation

• Lights and all accessories:

OFF

• Transmission: Neutral <M/T>

or P range <A/T>

0

− 3 mm3/st

491 Fuel

injection

quantity

pilot 2

Indicates the pilot injection

quantity

• Engine: After warm-up, idle

operation

• Lights and all accessories:

OFF

• Transmission: Neutral <M/T>

or P range <A/T>

0

− 3 mm3/st

492 Fuel

injection

quantity

pilot 3

Indicates the pilot injection

quantity

• Engine: After warm-up, idle

operation

• Lights and all accessories:

OFF

• Transmission: Neutral <M/T>

or P range <A/T>

0

− 3 mm3/st

Ite

m

No.

Inspectio

n item

Explanation of M.U.T. display

Guideline for inspection

Display range,

numerical

value