Mazda CX 7. Manual - part 45

ON-BOARD DIAGNOSTIC [L3 WITH TC]

01-02–135

01-02

End Of Sie

DTC P0421[L3 WITH TC]

id010239807300

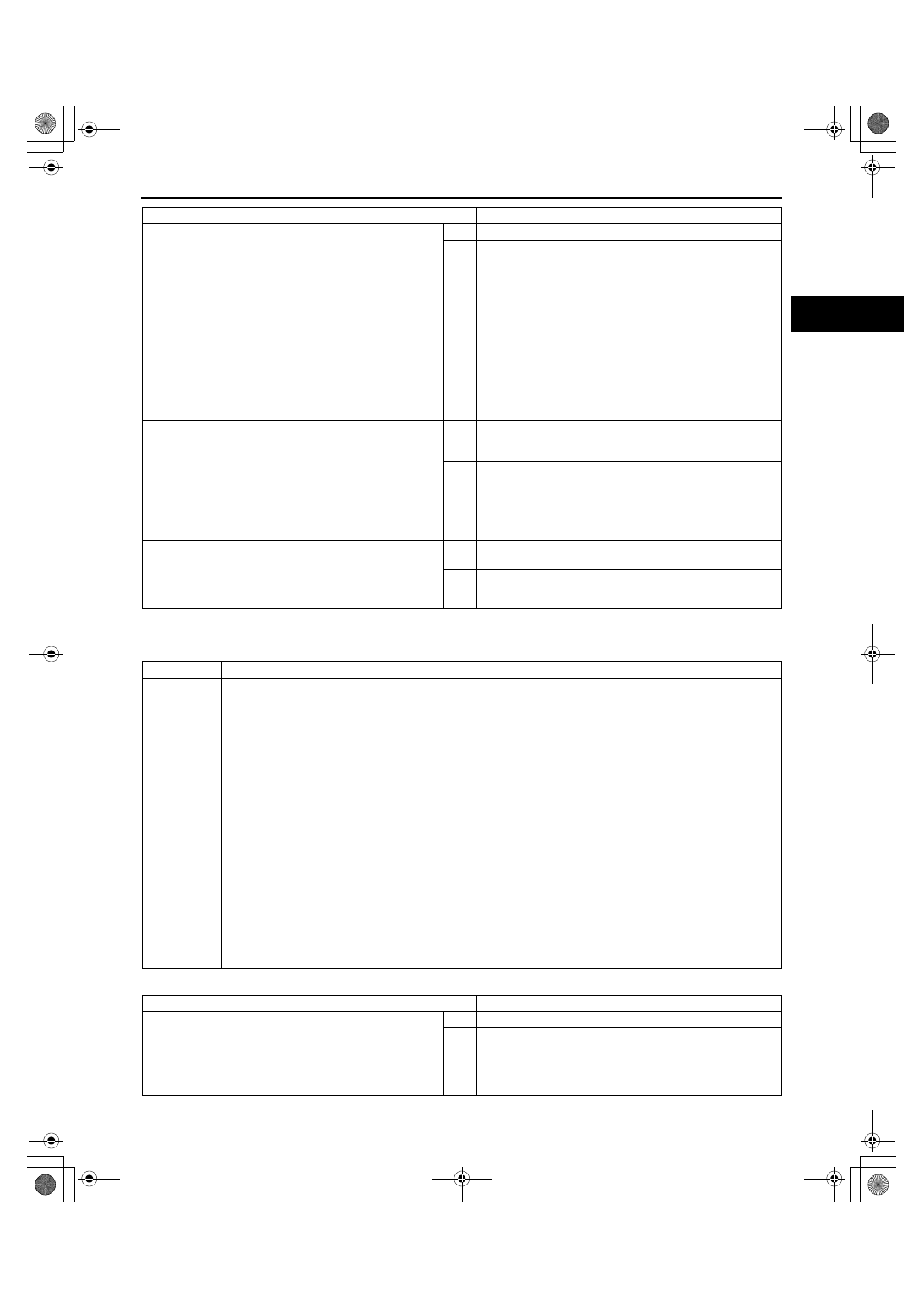

Diagnostic procedure

9

INSPECT CONTROL CIRCUIT FOR OPEN

CIRCUIT

• Remove the PCM with PCM connector

connected.

• Inspect for continuity between the following

terminals (harness-side):

— Between EGR valve terminal E and PCM

terminal 2AQ

— Between EGR valve terminal A and PCM

terminal 2AM

— Between EGR valve terminal B and PCM

terminal 2AR

— Between EGR valve terminal F and PCM

terminal 2AN

• Is there continuity?

Yes

Go to the next step.

No

Repair or replace harness for open circuit then go to the

next step.

10

VERIFY TROUBLESHOOTING OF DTC P0403

COMPLETED

• Make sure to reconnect all disconnected

connectors.

• Clear the DTC from the PCM memory using

the M-MDS.

• Turn the ignition switch off.

• Start the engine and warm it up completely.

• Is the PENDING CODE for this DTC present?

Yes

Replace the PCM, then go to the next step.

(See01-40-6 PCM REMOVAL/INSTALLATION[L3 WITH

TC].)

No

Go to the next step.

11

VERIFY AFTER REPAIR PROCEDURE

• Perform the “AFTTER REPAIR PROCEDURE”.

(See01-02-10 AFTER REPAIR

PROCEDURE[L3 WITH TC].)

• Are any DTCs present?

Yes

Go to the applicable DTC inspection.

(See01-02-13 DTC TABLE[L3 WITH TC].)

No

Troubleshooting completed.

STEP

INSPECTION

ACTION

DTC P0421

Warm up catalyst system efficiency below threshold

DETECTION

CONDITION

• The PCM compares the number of front HO2S and rear HO2S inversions for a predetermined time. The

PCM monitors the number of inversions the rear side performs while the front side inverts for a specified

number of times when the following monitoring conditions are met. The PCM detects the inversion ratio. If

the inversion ratio is below the threshold, The PCM determines that the catalyst system has deteriorated.

MONITORING CONDITIONS

— Engine speed:1,500— 3,000 rpm

— Calculated TWC temperature: above 400

°C {752 °F}

— LOAD:15— 48% (at engine speed of 2,000 rpm)

Diagnostic support note

• This is an intermittent monitor (Catalyst).

• The MIL illuminates if the PCM detects the above malfunction condition in two consecutive drive cycles or

in one drive cycle while the DTC for the same malfunction has been stored in the PCM.

• PENDING CODE is available if the PCM detects the above malfunction condition during the first drive

cycle.

• DIAGNOSTIC MONITORING TEST RESULTS is available.

• FREEZE FRAME DATA is available.

• The DTC is stored in the PCM memory.

POSSIBLE

CAUSE

• TWC deterioration or malfunction

• Exhaust gas leakage

• Loose front HO2S

• Loose rear HO2S

• PCM malfunction

STEP

INSPECTION

ACTION

1

VERIFY FREEZE FRAME DATA AND

DIAGNOSTIC MONITORING TEST RESULTS

HAVE BEEN RECORDED

• Have the FREEZE FRAME DATA and

DIAGNOSTIC MONITORING TEST RESULTS

(Catalyst related) been recorded?

Yes

Go to the next step.

No

Record the FREEZE FRAME DATA and DIAGNOSTIC

MONITORING TEST RESULTS on the repair order, then

go to the next step.

1871-1U-06B(01-02).fm 135 ページ 2006年3月15日 水曜日 午前10時32分