Mazda 6. Manual - part 363

ON-BOARD DIAGNOSTIC [AIR BAG SYSTEM]

T–199

T

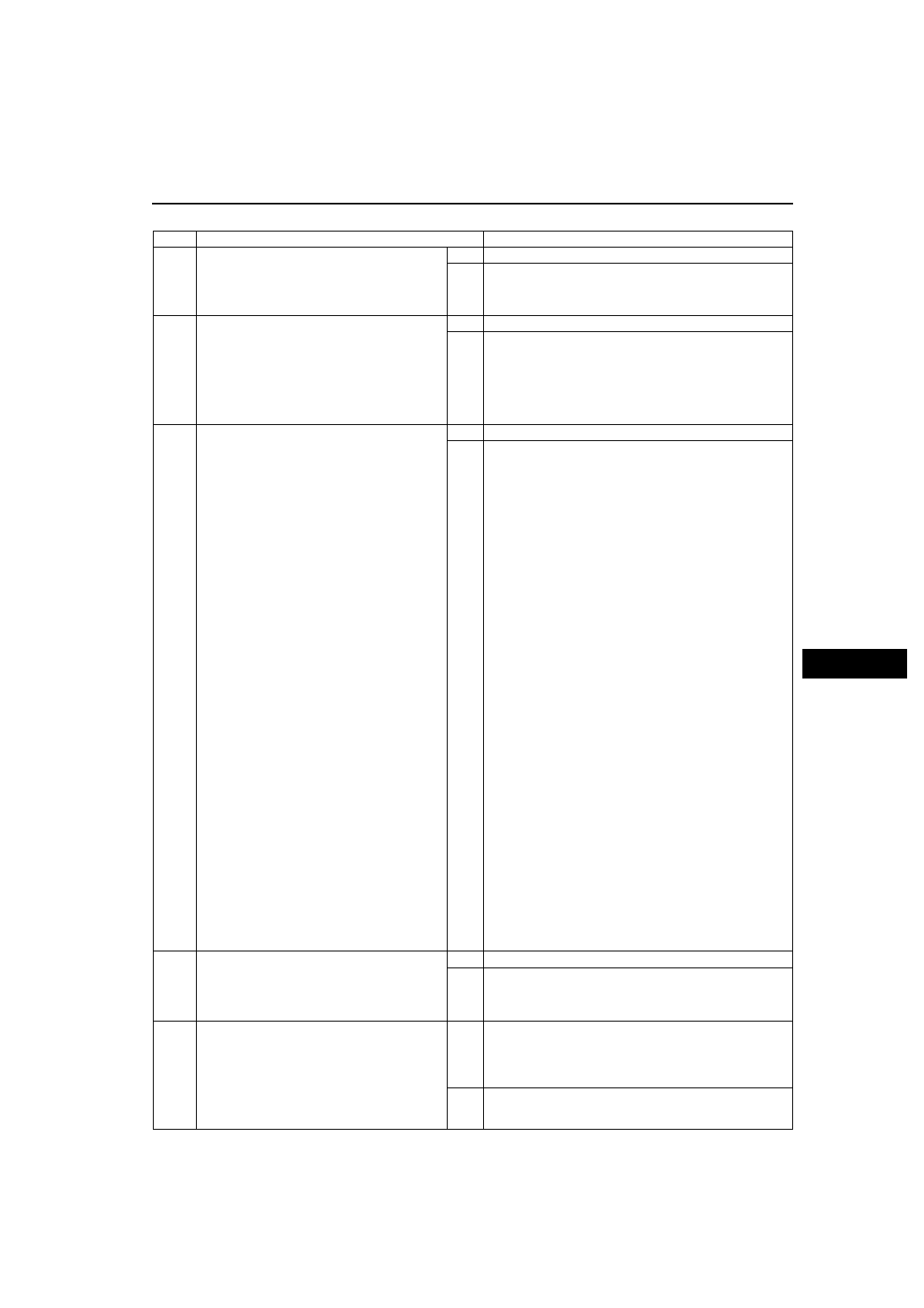

Diagnostic procedure

STEP

INSPECTION

ACTION

1

INSPECT METER IG 15 A FUSE

• Turn ignition switch to LOCK position.

• Disconnect negative battery cable.

• Remove METER IG 15 A fuse.

• Is fuse okay?

Yes

Reinstall METER IG 15 A fuse, then go to next step.

No

Replace METER IG 15 A fuse.

2

INSPECT FOR CONTINUITY BETWEEN

METER IG 15 A FUSE AND INSTRUMENT

CLUSTER

• Connect negative battery cable.

• Turn ignition switch to ON position.

• Measure voltage at instrument cluster

connector terminal 2V.

• Is voltage more than 9 V?

Yes

Go to next step.

No

Repair wiring harness.

3

INSPECT WIRING HARNESS BETWEEN

INSTRUMENT CLUSTER AND SAS UNIT

Warning

• Handling air bag system components

improperly can accidentally deploy air

bag modules and pre-tensioner seat

belts, which may seriously injure you.

Read AIR BAG SYSTEM SERVICE

WARNINGS before handling air bag

system components.

(See

• Turn ignition switch to LOCK position.

• Disconnect negative battery cable and wait

for more than 1 minute.

• Remove column cover.

• Disconnect clock spring connector.

• Remove glove compartment.

• Disconnect passenger-side air bag module

connector.

• Disconnect driver and passenger-side

curtain air bag module connectors. (Vehicles

with curtain air bag)

• Disconnect driver and passenger-side side

air bag module connectors. (Vehicles with

side air bag)

• Remove B-pillar lower trims. (Vehicle with

pre-tensioner seat belt)

• Disconnect driver and passenger-side pre-

tensioner seat belt connectors. (Vehicle with

pre-tensioner seat belt)

• Turn up floor covering.

• Disconnect all SAS unit connectors.

• Disconnect instrument cluster.

• Inspect following wiring harness between

SAS unit and instrument cluster terminals for

short to ground, short to power supply, and

open circuit:

— 1T—1O

• Is wiring harness okay?

Yes

Go to next step.

No

Replace wiring harness.

4

INSPECT AIR BAG SYSTEM WARNING

LIGHT

• Connect instrument cluster.

• Turn ignition switch to ON position.

• Is air bag system warning light illuminated?

Yes

Go to next step.

No

Replace instrument cluster.

(See

T–72 INSTRUMENT CLUSTER REMOVAL/

)

5

INSPECT AIR BAG SYSTEM WARNING

LIGHT

• Using a jumper wire, cause a short circuit

between instrument cluster terminal 1O and

ground.

• Does air bag system warning light go out?

Yes

[Present malfunction diagnosis]

Replace SAS unit.

(See

T–124 SAS UNIT REMOVAL/INSTALLATION

)

[Past malfunction diagnosis]

Troubleshooting completed.

No

Replace instrument cluster.

(See

T–72 INSTRUMENT CLUSTER REMOVAL/

)