Mazda 6. Manual - part 172

F–210

TROUBLESHOOTING

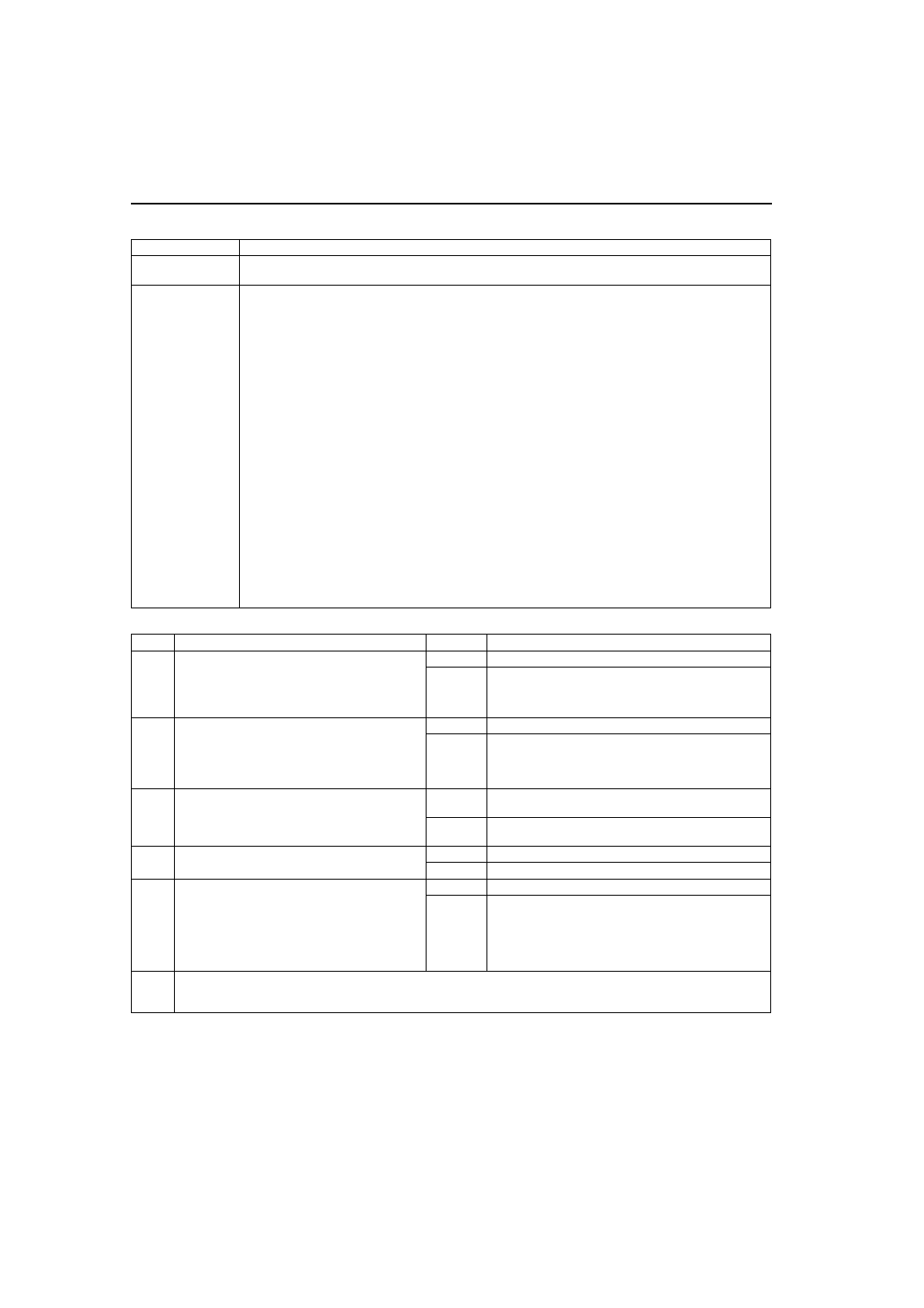

NO.13 KNOCKING/PINGING-ACCELERATION/CRUISE

A6E398018881W15

Diagnostic procedure

End Of Sie

13

KNOCKING/PINGING - ACCELERATION/CRUISE

DESCRIPTION

Sound is produced when air/fuel mixture is ignited by something other than spark plug (e.g., hot spot in

combustion chamber).

POSSIBLE CAUSE

• Engine overheating due to cooling system malfunction

• ECT sensor malfunction

• IAT sensor malfunction

• MAF sensor malfunction

• Knock sensor malfunction

• Erratic signal from CMP sensor

• Inadequate engine compression

• Inadequate fuel pressure

Warning

The following troubleshooting flow chart contains the fuel system diagnosis and repair

procedures. Read the following warnings before performing the fuel system services:

• Fuel vapor is hazardous. It can easily ignite, causing serious injury and damage. Always

keep sparks and flames away from fuel.

• Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or

death and damage. Fuel can also irritate skin and eyes. To prevent this, always complete

"BEFORE REPAIR PROCEDURE" and "AFTER REPAIR PROCEDURE" described in this

manual.

(See

.)

(See

.)

Caution

• Disconnecting/connecting quick release connector without cleaning it may possibly cause

damage to fuel pipe and quick release connector. Always clean quick release connector

joint area before disconnecting/connecting, and make sure that it is free of foreign material.

STEP

INSPECTION

RESULTS

ACTION

1

Connect WDS or equivalent to DLC-2.

Access ECT PID.

Verify ECT PID is less than 116

°C {241°F}

during driving.

Is ECT PID less than specification?

Yes

Go to next step.

No

Inspect cooling system for cause of overheating.

2

Connect WDS or equivalent to DLC-2.

Access IAT, MAF and SPARKADV PIDs.

Monitor each PID.

(See

.)

Are PIDs okay?

Yes

Go to next step.

No

IAT PID: Inspect IAT sensor

MAF PID: Inspect MAF sensor

SPARKADV PID: Inspect CMP sensor and knock

sensor.

3

Connect WDS or equivalent to DLC-2.

Retrieve any continuous memory, KOEO and

KOER DTCs.

Are there any DTCs displayed?

Yes

DTC is displayed:

Go to appropriate DTC test.

No

No DTC is displayed:

Go to next step.

4

Is engine compression correct?

Yes

Go to next step.

No

Inspect for cause.

5

Install fuel pressure gauge between fuel pipe

and fuel distributor.

Start engine and run it at idle.

Measure fuel line pressure at idle.

Is fuel line pressure correct at idle?

(See

Yes

Inspect ignition timing.

No

Zero or low:

Inspect for clogged fuel line.

If okay, replace fuel pump unit.

High:

Replace fuel pump unit.

6

Verify test results.

• If okay, return to diagnostic index to service any additional symptoms.

• If malfunction remains, replace PCM.