Engine JAC HFC4DA1-2C. Manual - part 131

MT

MT

MT

MT Manual

Manual

Manual

Manual Transmission

Transmission

Transmission

Transmission

-44-

Care

Care

Care

Care and

and

and

and maintenance

maintenance

maintenance

maintenance

Transmission

Transmission

Transmission

Transmission maintenance

maintenance

maintenance

maintenance

1.

Transmission operation and maintenance should be conducted in accordance with application and maintenance

requirements for commercial vehicles, which are generally divided into three technical maintenance stages.

2.

Check, change (or add) transmission oil regularly.

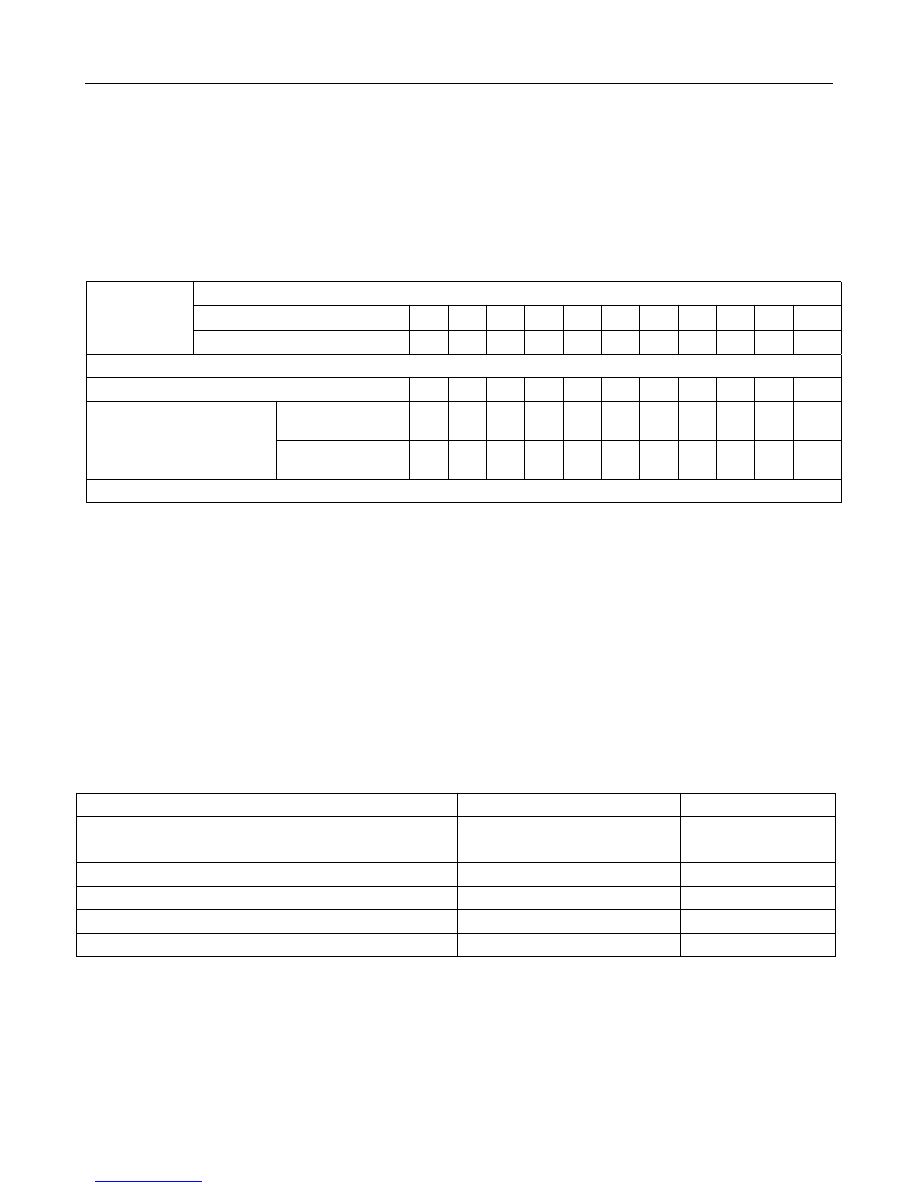

Regular Inspection and Maintenance Schedule for Transmission

Mileage and time (by the month) are both indicated for each item, whichever occurs first.

○ Check point, tighten or adjust; ★ Change lube oil

Item

Service interval (based on odometer reading or number of months, which occurs first)

Number of months

-

3

6

12

18

24

30

36

42

48

54

Odometer reading×1000km

1

5

10

20

30

40

50

60

70

80

90

Transmission inside inspection

Check gear oil level inside transmission

○

○

○

○

○

Change

gear

oil

inside

transmission

Normal

service

condition

★

★

★

★

★

Severe

service

condition

★

★

★

★

★

★

★

★

Other inspections

Note: “Severe service condition” includes items listed below:

1.

Running in dusty areas or frequently exposed in salty atmosphere or saline water.

2.

Running on bumpy, water-logging roads or on mountain road.

3.

Running in cold areas.

4.

Engine idling for a long time or frequent short distance running in cold seasons.

5.

Frequent application of brakes and emergency brake.

6.

Towing vehicle.

7.

Under high temperature over 32℃, the time of vehicle running slowly in congested urban areas exceeding 50%

of total running time.

8.

Under high temperature over 30℃, the time of vehicle running at high speed over 120km/h exceeding 50% of

total running time.

9.

Overloading.

Lubrication and seal

Item

Item

Item

Item

Lube

Lube

Lube

Lube Oil/Sealant

Oil/Sealant

Oil/Sealant

Oil/Sealant

Qty.

Qty.

Qty.

Qty.

Transmission gear oil

Gear oil

In summer 80W/90 GL-4

In winter 75W/90 GL-4

2.7L

Release bearing bore of transmission

Grease

Adequate

Transmission oil seal

Grease

Adequate

Mating face between transmission housing and clutch housing

TONSAN®1596F

Adequate

Mating face between transmission housing and rear cover

TONSAN®1596F

Adequate