Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 547

1A–56 HEATING, VENTILATION AND AIR CONDITIONING (HVAC)

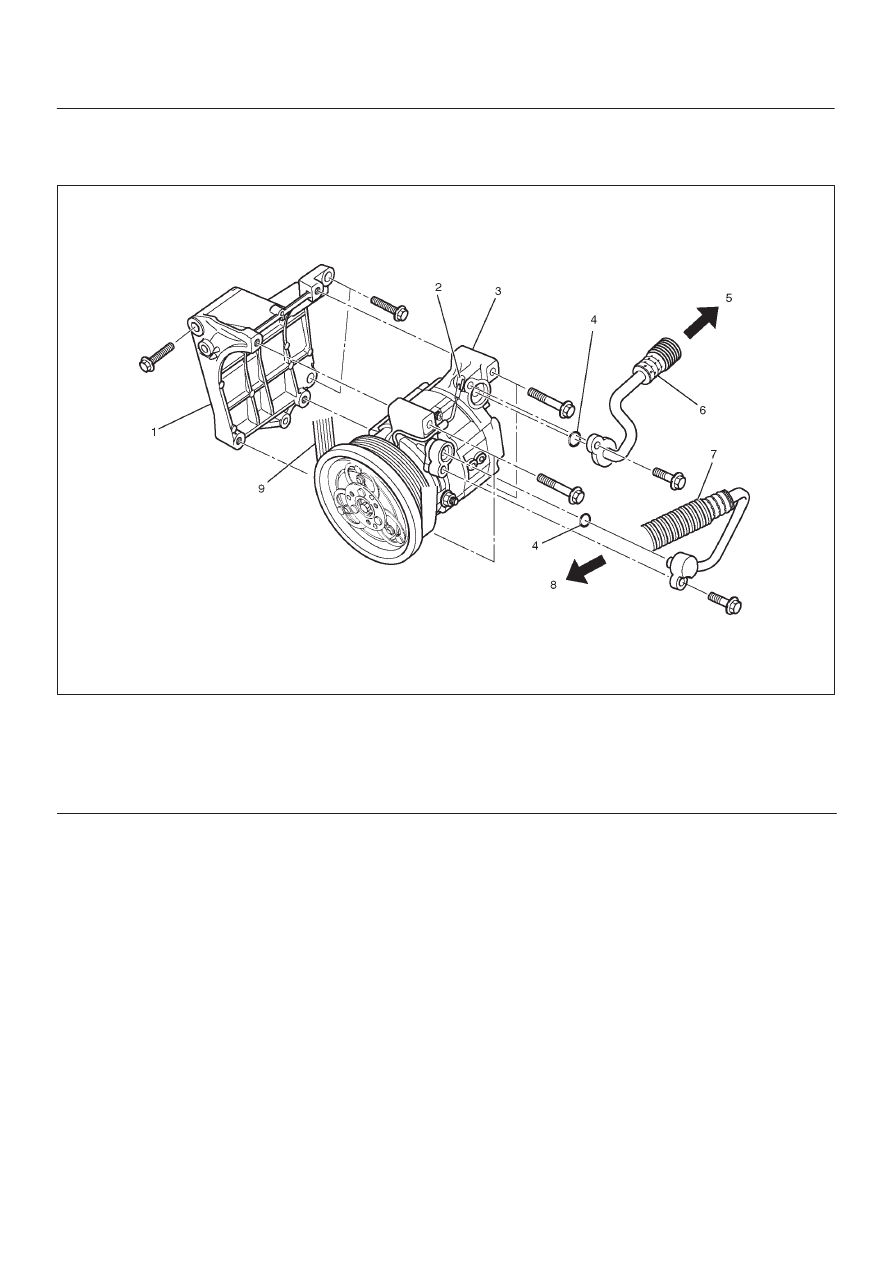

Compressor Assembly

Compressor Assembly and Associated Parts (6VE1)

852R200013

Legend

(1) Compressor Bracket

(2) Magnetic Clutch Harness Connector

(3) Compressor

(4) O-ring

(5) To Evaporator

(6) Suction Line (Low-Pressure Hose)

(7) Discharge Line (High-Pressure Hose)

(8) To Condenser

(9) Serpentine Belt

Removal

1. Disconnect the battery ground cable.

2. Discharge and recover refrigerant

D

Refer to Refrigerant Recovery in this section.

3. Disconnect magnetic clutch harness connector.