Isuzu engine C22NE / 22LE / 20LE. Manual - part 84

DRIVEABILITY AND EMISSIONS 6E1-165

DIAGNOSTIC TROUBLE CODE (DTC) (Flash DTC = 18)

DIGITALLY CONTROLED SIGNAL TO NOISE ENHANCEMENT FILTER FAILURE

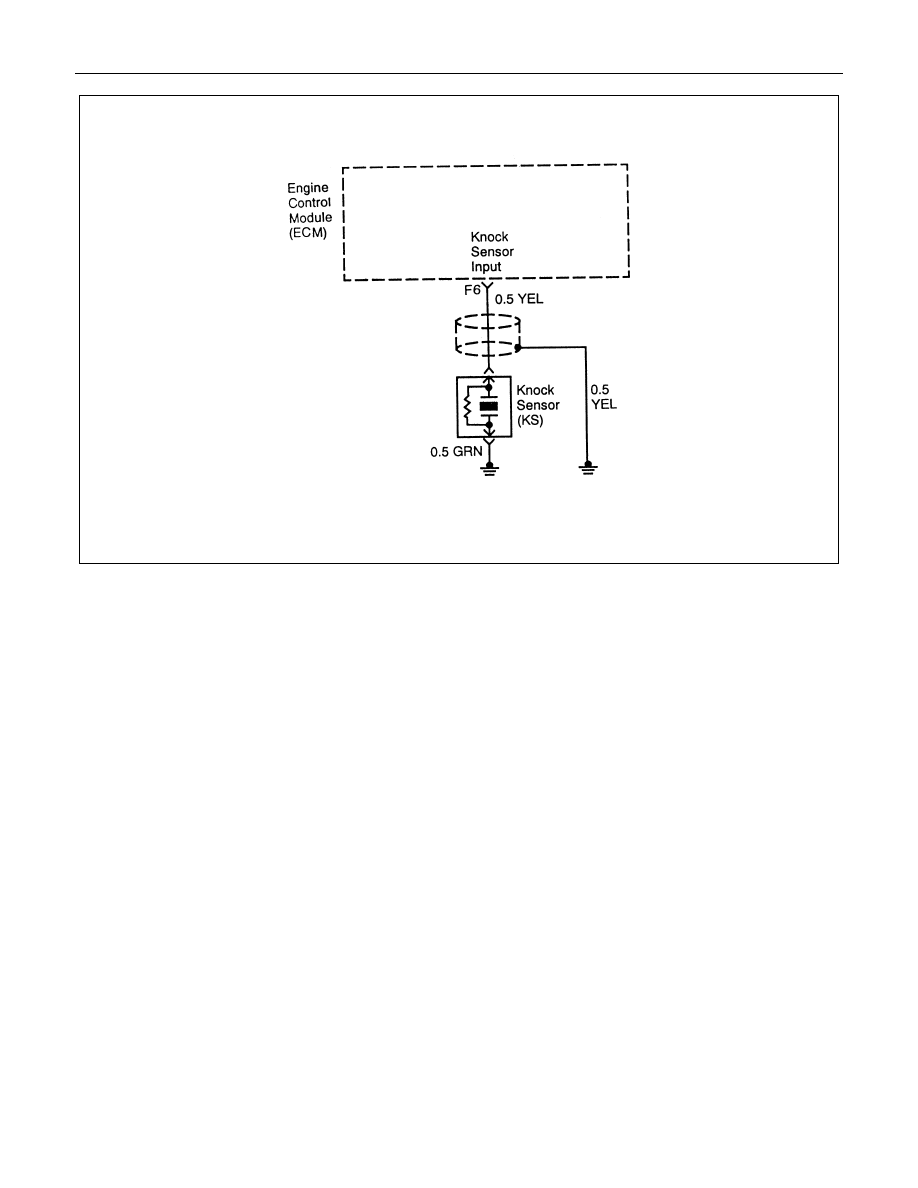

Circuit Description

The knock sensor (KS) system is used to detect

engine detonation. The knock sensor produced an AC

voltage signal. The knock sensor sends this signal to

the ECM. The amplitude and the frequency of the AC

voltage signal depends upon the knock level being

detected. The ECM will then retard the spark timing

based on the signals from the Knock Sensor.

This code detects a digitally controlled signal to noise

enhancement filter failure. Then the DTC 18 will set.

Conditions for Setting the DTC

• ECM powered up, Engine running, Electronic spark

control enabled and Engine rpm is greater than 96

rpm.

• Malfunction 16 is not triggered.

Action Taken When the DTC Sets

• The Malfunction Indicator Lamp (MIL) will illuminate

the second time the fault is detected.

• The ECM will use a calculated spark retard value in

order to minimize the knock during the conditions

when the knock is likely to occur. The calculated

value will vary based on the engine speed and load.

Conditions for Clearing the MIL/DTC

Once the ECM determines that a fault(s) has been

rectified then the CEL will switch OFF, although the

fault code will remain in the ECM memory.

Any fault codes will remain in ECM memory until -

1. They are cleared by disconnecting the Battery for

more than 30 seconds.

2. A service tool such as Tech 2 is used to clear them.

3. Ten consecutive starts without logging a fault.

Diagnostic Aids

Correct any abnormal engine noise before using the

diagnostic table.

Check for an open ignition feed circuit.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Table.

2. If the conditions for the test as described above are

met, a Diagnostic Trouble Code 18 will set and MIL

will illuminate.