Isuzu engine C22NE / 22LE / 20LE. Manual - part 81

DRIVEABILITY AND EMISSIONS 6E1-153

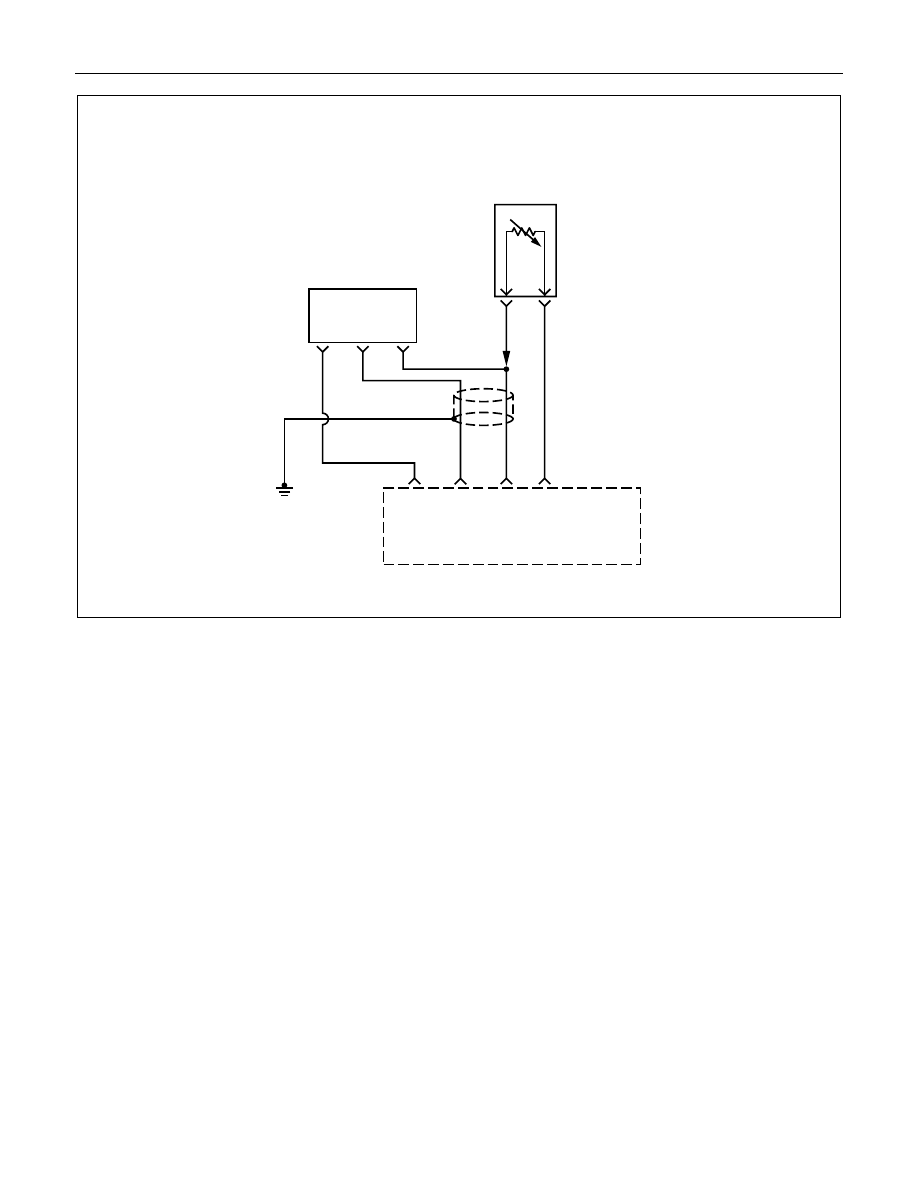

0.75

G

0.75

L

0.5

R

0.5

GRN

0.5

L/R

Engine

Control

Module

(ECM)

A3

F14

B1

B8

ECT

Sensor

Input

Sensor

Ground

Engine

Coolant

Temperature

(ECT)

Sensor

B

A

TPS

HI

OUT

LO

DIAGNOSTIC TROUBLE CODE (DTC) (Flash DTC = 14)

ENGINE COOLANT TEMPERATURE (ECT) SENSOR CIRCUIT HIGH INPUT

Circuit Description

The engine coolant temperature (ECT) sensor is a

thermistor mounted in the engine coolant stream. The

engine control module (ECM) applies a voltage (about

5 volts) through a pull-up resistor to the ECT signal

circuit. When the engine coolant is cold, the sensor

(thermistor) resistance is high, therefore the ECM will

measure a high signal voltage. As the engine coolant

warms, the sensor resistance becomes lower, and the

ECT signal voltage measured at the ECM drops. With

a fully warmed up engine, the ECT signal voltage

should measure about 1.5 to 2.0 volts. If the ECM

detect a continuous open in the ECT sensor or circuit,

then a code 14 will set.

Conditions for Setting the DTC

• Engine running time is longer than 10secs.

• The ECT sensor signal indicates an engine coolant

temperature greater than 140°C (284°F).

Action Taken When the DTC Sets

• The ECM will illuminate the malfunction indicator

lamp (MIL) fault is detected.

• The ECM will substitute the ECT reading with a

default engine coolant temperature value. The

default value is based on start-up intake air

temperature and running time.

Conditions for Clearing the MIL/DTC

Once the ECM determines that a fault(s) has been

rectified then the CEL will switch OFF, although the

fault code will remain in the ECM memory.

Any fault codes will remain in ECM memory until -

1. They are cleared by disconnecting the Battery for

more than 30 seconds.

2. A service tool such as Tech 2 is used to clear them.

3. Ten consecutive starts without logging a fault.