Isuzu engine C22NE / 22LE / 20LE. Manual - part 73

DRIVEABILITY AND EMISSIONS 6E1-121

Fuel System Diagnosis (Cont'd)

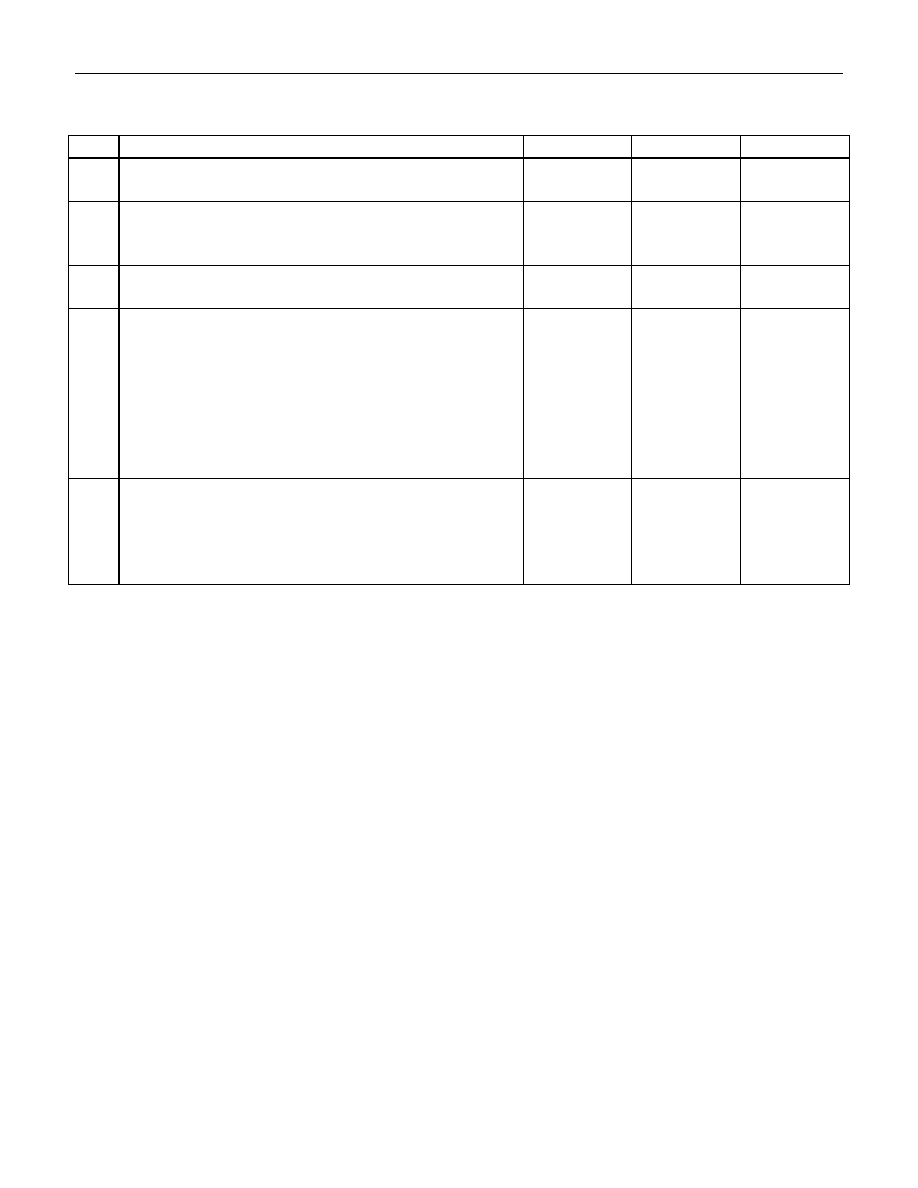

Step

Action

Value(s)

Yes

No

19

Locate and correct the restriction in the fuel return line.

Is the action complete?

-

Verify repair

-

20

Visually and physically inspect the fuel rail outlet passages

for a restriction.

Was a restriction found?

-

Verify repair

Go to Step 11

21

Is the fuel pressure indicated by the fuel pressure gauge

above the specified value?

0 kPa (0 psi)

Go to Step 22

Go to Step 23

22

1. Command the fuel pump ON with the Scan Tool.

2. Using suitable pliers which will not damage the fuel

hose, gradually apply pressure with the pliers to pinch

the flexible fuel return hose closed.

Does the fuel pressure indicated by the fuel pressure

gauge rise above the first specified value?

Caution: Do not let the fuel pressure exceed the

second specified value.

376 kPa

(55 psi)

414 kPa

(60 psi)

Go to Step 11

Go to Step 7

23

1. Command the fuel pump ON with the Scan Tool.

2. Remove the fuel filler cap and listen for the sound of

the fuel pump running.

3. Turn the pump off.

Was the fuel pump running?

-

Go to Step 7

Go to

Fuel System

Electrical

Test Chart