Isuzu Trooper (1998-2002 year). Manual - part 777

TRANSMISSION CONTROL SYSTEM (4L30–E)

7A1–17

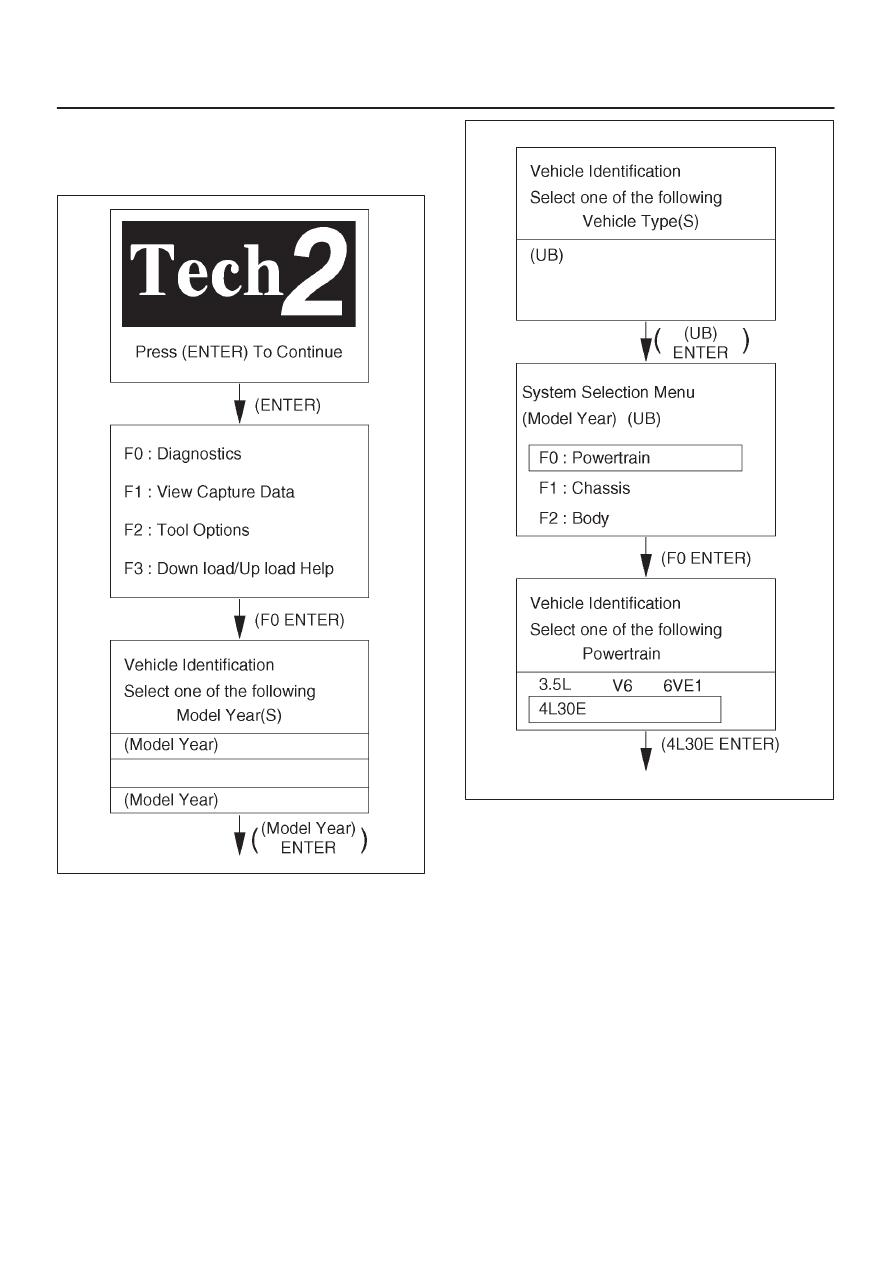

8. The power up screen is displayed when you

power up the tester with the Isuzu systems

PCMCIA card. Follow the operating procedure

below.

060R200264

060R200265