Isuzu Trooper (1998-2002 year). Manual - part 551

6A – 12 ENGINE MECHANICAL

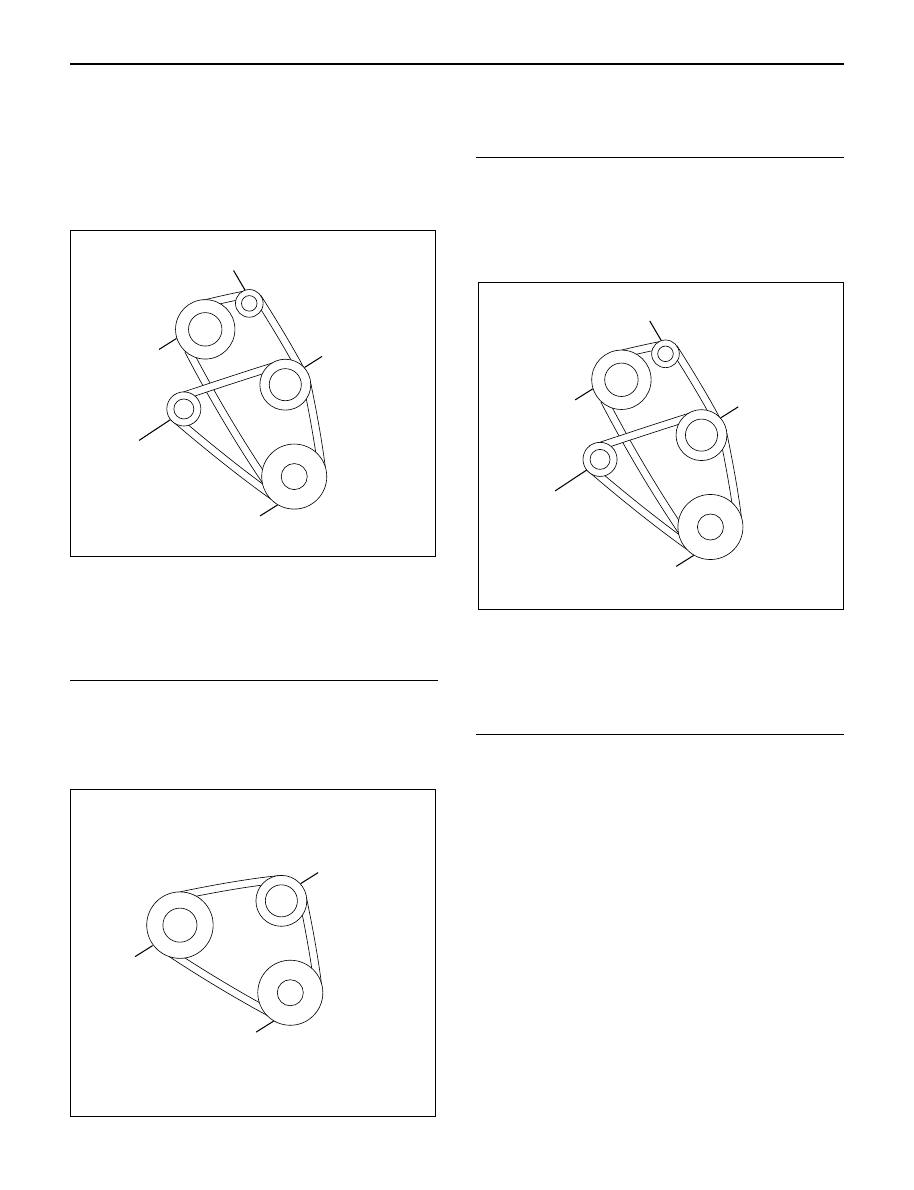

Drive Belt Adjustment

Check the drive belt tension

Depress the drive belt mid-portion with a 98 N (10 kg/

22 lb) force.

Drive Belt Deflection: 10 mm (0.39 in)

Check the drive belt for cracking and other damage.

Legend

(1) Crankshaft pulley

(2) Generator pulley

(3) Cooling fan pulley

(4) A/C compressor pulley

(5) Belt tensioner pulley

Cooling Fan Pulley Drive Belt

Fan belt tension is adjusted by moving the generator.

Depress the drive belt mid-portion with a 98 N (10 kg/

22 lb) force.

Legend

(1) Crankshaft pulley

(2) Generator pulley

(3) Cooling fan pulley

Compressor Pulley Drive Belt

Move the tensioner pulley as required to adjust the

compressor drive belt tension.

Depress the drive belt mid-portion with a 98 N (10 kg/

22 lb) force.

Legend

(1) Crankshaft pulley

(2) Generator pulley

(3) Cooling fan pulley

(4) A/C compressor pulley

(5) Belt tensioner pulley

5

3

2

4

1

012RW110

3

2

1

012RW084

5

3

2

4

1

012RW110