Isuzu Trooper (2000 year). Manual - part 438

7C–16

CLUTCH

Installation

1. Install damper cylinder assembly.

2. Install master cylinder assembly.

3. Install slave cylinder assembly and heat protector.

4. Install oil line pipe.

5. Install pedal assembly and switch.

6. Install pin and jaw joint pin.

Adjustment

Clutch Pedal Adjustment

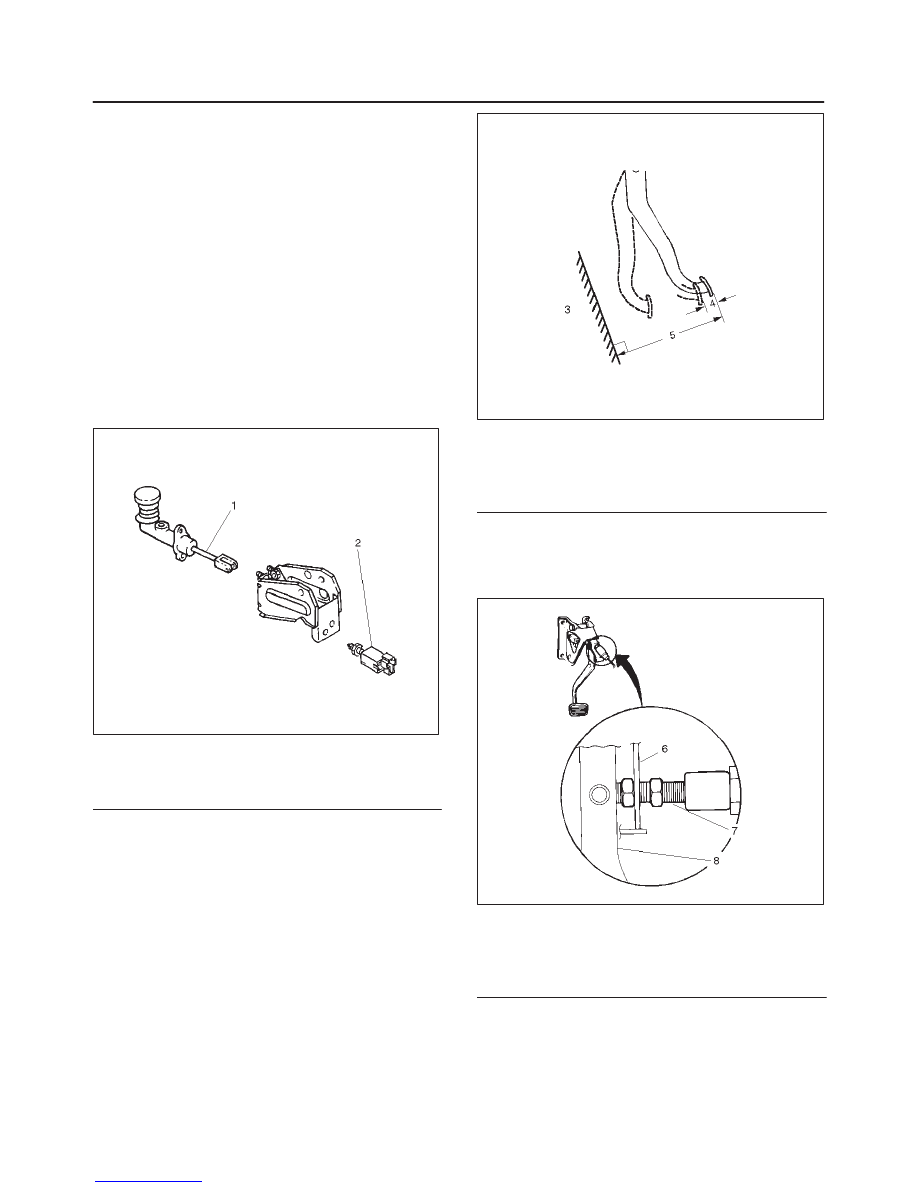

1. With clutch switch

1. Disconnect clutch switch (2) connector.

2. Loosen lock nut, then turn switch out until there is

a gap between the switch plunger and clutch

pedal.

203RW003

Legend

(1) Push Rod

(2) Clutch Switch

2. Loosen clutch master cylinder push rod lock nut. Turn

push rod by hand to set clutch pedal height (5) to

within specification.

Clutch pedal height (5): 217 mm – 227 mm

(8.543 in – 8.937 in)

203RW004

Legend

(3) Floor Panel

(4) Pedal Free Play

(5) Clutch Pedal Height

3. Tighten push rod lock nut.

4. With clutch switch

1. Turn the clutch switch until the switch bolt just

touches the clutch pedal arm.

203RW005

Legend

(6) Blacket

(7) Clutch Switch Bolt

(8) Clutch Pedal Arm