Isuzu Rodeo UE. Manual - part 181

6E1–95

RODEO X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

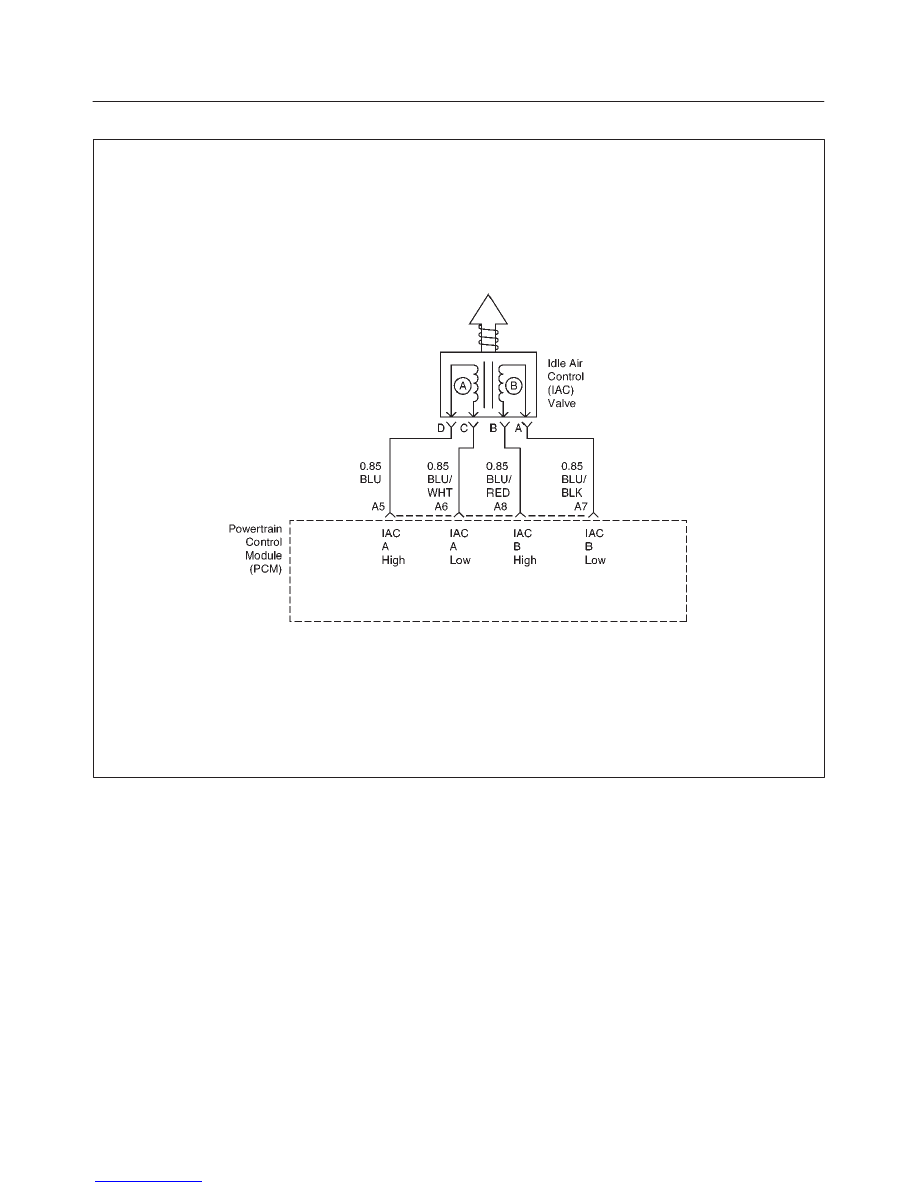

IDLE AIR CONTROL (IAC) SYSTEM CHECK

D06RX041

Circuit Description

The powertrain control module (PCM) controls engine

idle speed with the idle air control (IAC) valve. To increase

idle speed, the PCM retracts the IAC valve pintle away

from its seat, allowing more air to bypass the throttle bore.

To decrease idle speed, it extends the IAC valve pintle

towards its seat, reducing bypass air flow. A Tech 2 will

read the PCM commands to the IAC valve in counts.

Higher counts indicate more air bypass (higher idle).

Lower counts indicate less air is allowed to bypass (lower

idle).

Diagnostic Aids

A slow, unstable, or fast idle may be caused by a non–IAC

system problem that cannot be overcome by the IAC

valve. Out of control range IAC Tech 2 counts will be

above 60 if idle is too low, and zero counts if idle is too

high. The following checks should be made to repair a

non–IAC system problem:

f

Vacuum leak (high idle) – If idle is too high, stop the

engine. Fully extend (low) IAC with the IAC motor

analyzer J 39027–A. Start the engine. If idle speed is

above 800 RPM, locate and correct the vacuum leak,

including the PCV system. Check for binding of the

throttle blade or linkage.

f

Lean heated oxygen sensor signal (high air/fuel ratio)

– The idle speed may be too high or too low. Engine

speed may vary up and down, and disconnecting the

IAC valve does not help. Diagnostic trouble codes

P0131, P0151, P0171, or P0174 may be set. Tech 2

oxygen (O2) voltage will be less than 100 mV (0.1 V).

Check for low regulated fuel pressure, water in fuel, or

a restricted injector.