Isuzu Rodeo UE. Manual - part 14

1A–26 HEATING, VENTILATION AND AIR CONDITIONING (HVAC)

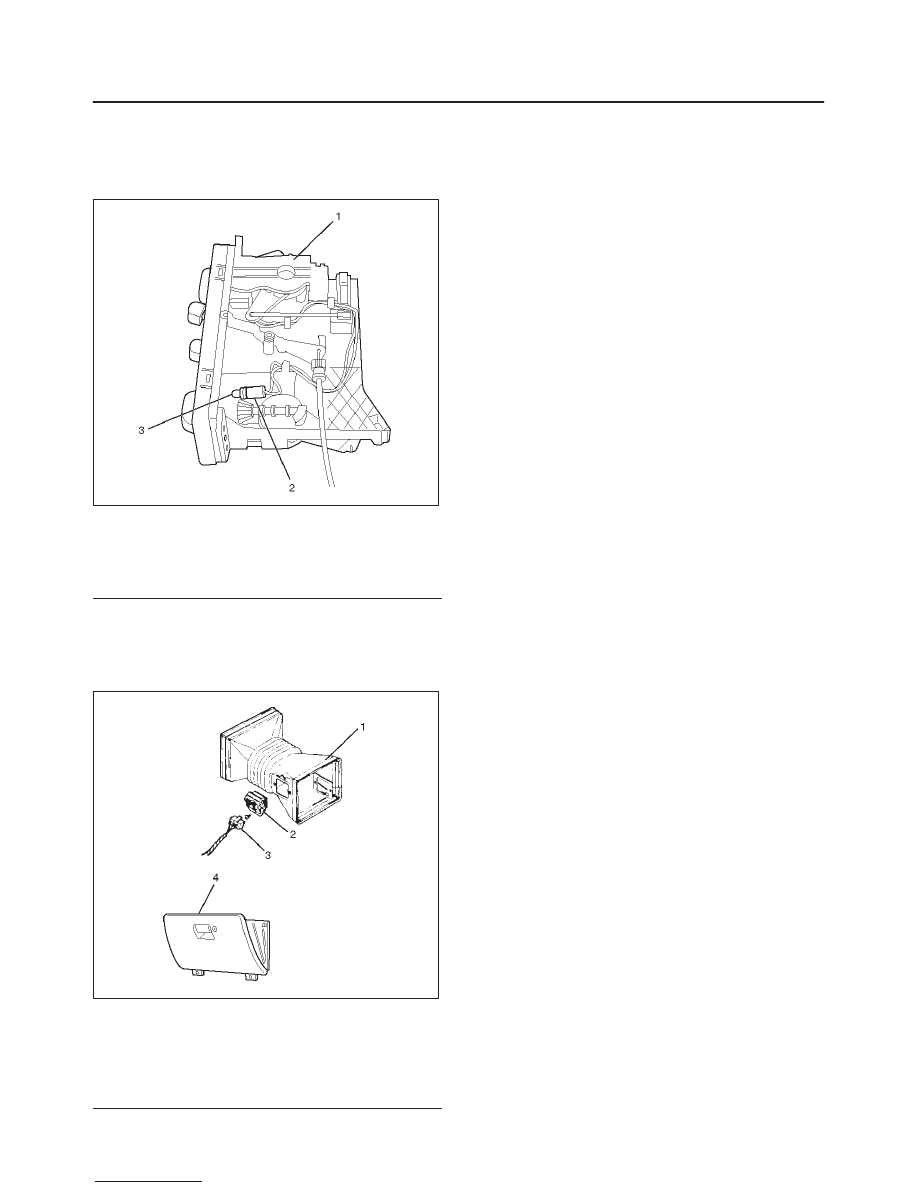

Control Panel Illumination Bulb

Control Panel Illumination Bulb and

Associated Parts

865RW003

Legend

(1) Control Lever Assembly

(2) Bulb Socket

(3) Illumination Bulb

Removal

1. Disconnect the battery ground cable.

2. Remove control lever assembly.

f

Refer to Control Lever Assembly in this section.

3. Pull out the bulb socket from the panel by turning it

counterclockwise.

4. Pull the illumination bulb from the socket.

Installation

To install, follow the removal steps in the reverse order.

Resistor

Resistor and Associated Parts

840RW001

Legend

(1) Duct (Heater only)

(2) Resistor

(3) Resistor Connector

(4) Glove Box

Removal

1. Disconnect the battery ground cable.

2. Remove glove box.

3. Remove resistor connector.

4. Remove duct (heater only).

5. Remove resistor.

Installation

To install, follow the removal steps in the reverse order.