Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual - part 871

6E–213

3.2L ENGINE DRIVEABILITY AND EMISSIONS

Hesitation, Sag, Stumble Symptom

(Cont'd)

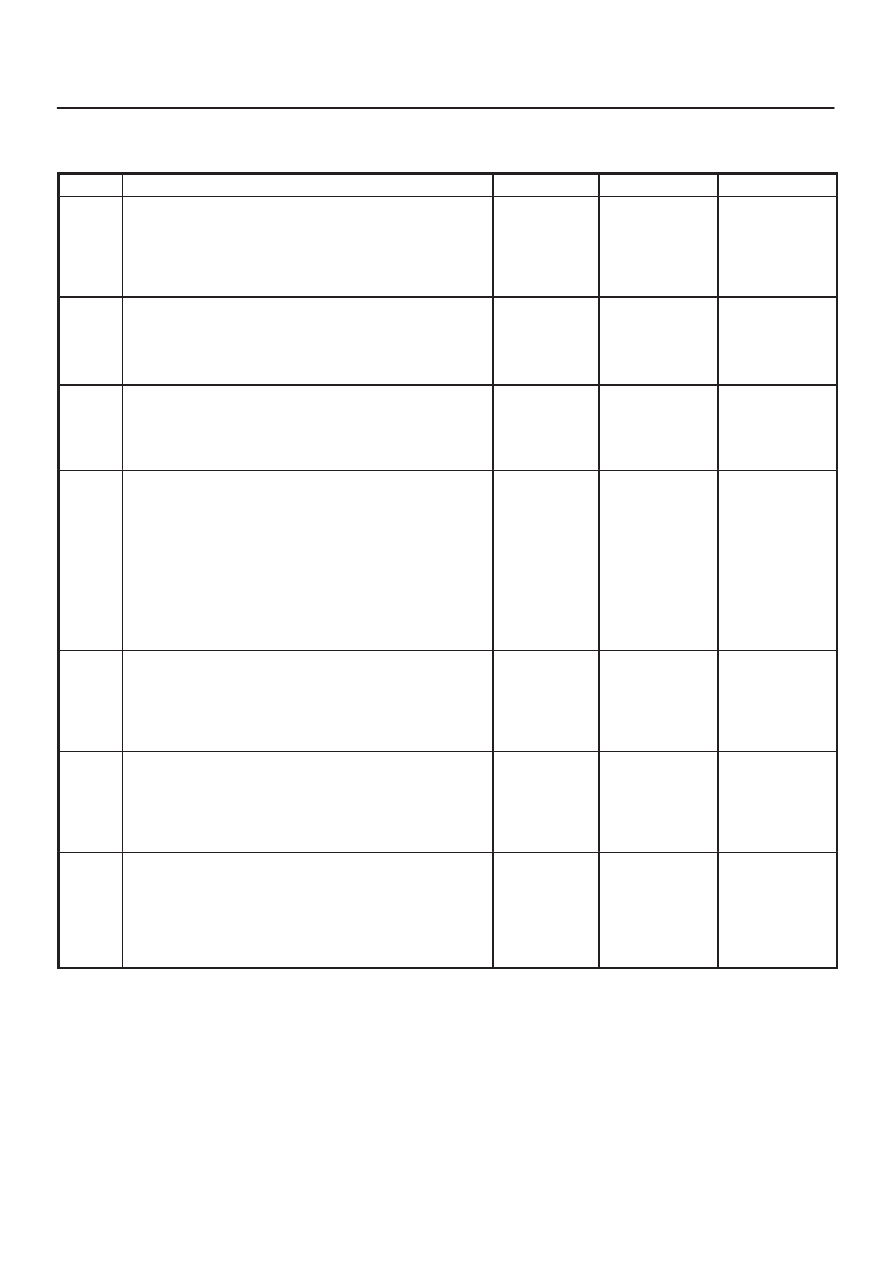

Step

No

Yes

Value(s)

Action

10

1. Check for proper ignition voltage output with spark

tester J 26792 (ST-125). Refer to

Electronic Ignition

System for the procedure.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 11

11

1. Check for a loose ignition coil ground.

Refer to

Electronic Ignition System.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 12

12

1. Check the ignition coils for cracks or carbon

tracking.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 13

13

1. Remove spark plugs and check for wet plugs,

cracks, wear, improper gap, burned electrodes, or

heavy deposits. Refer to

Electronic Ignition

System.

NOTE: If spark plugs are gas or oil fouled, the cause of

the fouling must be determined before replacing the

spark plugs.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 14

14

1. Check the ECM grounds for clearness, tightness

and proper routing. Refer to the ECM wiring

diagrams in Electrical Diagnosis.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 15

15

1. Check the MAF sensor connections.

2. If a problem is found, replace the faulty terminals as

necessary. Refer to

Electrical Diagnosis for wiring

repair procedures.

Was a problem found?

—

Verify repair

Go to

Step 16

16

1. Visually/physically check vacuum hoses for splits,

kinks, and proper connections and routing as

shown on the “Vehicle Emission Control

Information” label.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 17