Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual - part 848

6E–121

3.2L ENGINE DRIVEABILITY AND EMISSIONS

DTC P0134 –HO2S Circuit Insufficient Activity

(Cont'd)

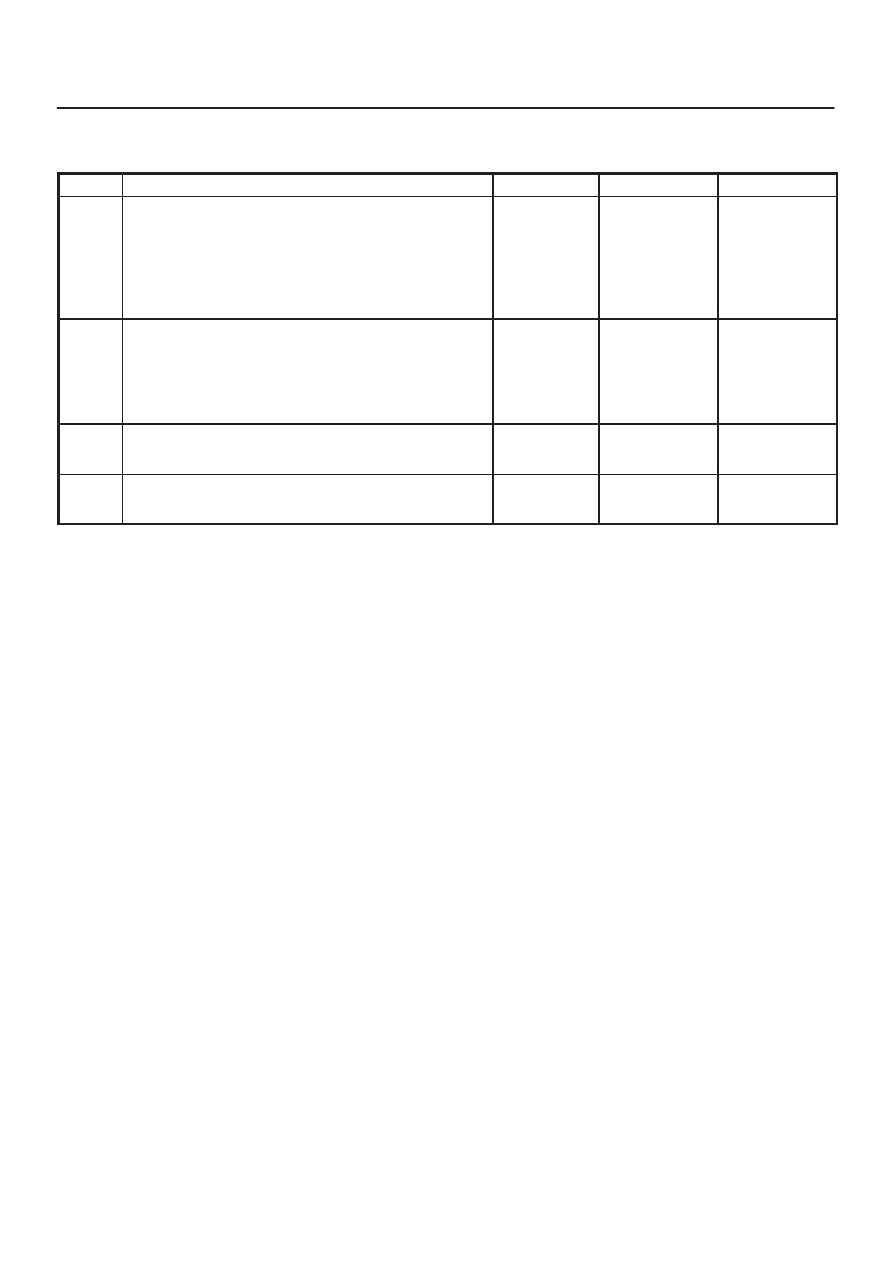

Step

No

Yes

Value(s)

Action

8

1. Ignition “OFF.”

2. With the ECM disconnected, check continuity of the

HO2S low circuit.

3. If the HO2S low circuit measures over 5 ohms,

repair open or poor connection as necessary.

Was a HO2S low circuit problem found and corrected?

—

Verify repair

Go to

Step 9

9

1. Ignition “ON,” engine “OFF.”

2. Disconnect HO2S and jumper the HO2S high and

low circuits (ECM side) to ground.

3. Using a Tech 2, monitor Bank 1 HO2S 1 voltage.

Is HO2S voltage in the specified range?

0-10 mV

Go to

Step 10

Go to

Step 11

10

Replace HO2S.

Is the action complete?

—

Verify repair

—

11

Replace the ECM.

Is the action complete?

—

Verify repair

—