Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual - part 784

6A–16

ENGINE MECHANICAL (6VD1 3.2L)

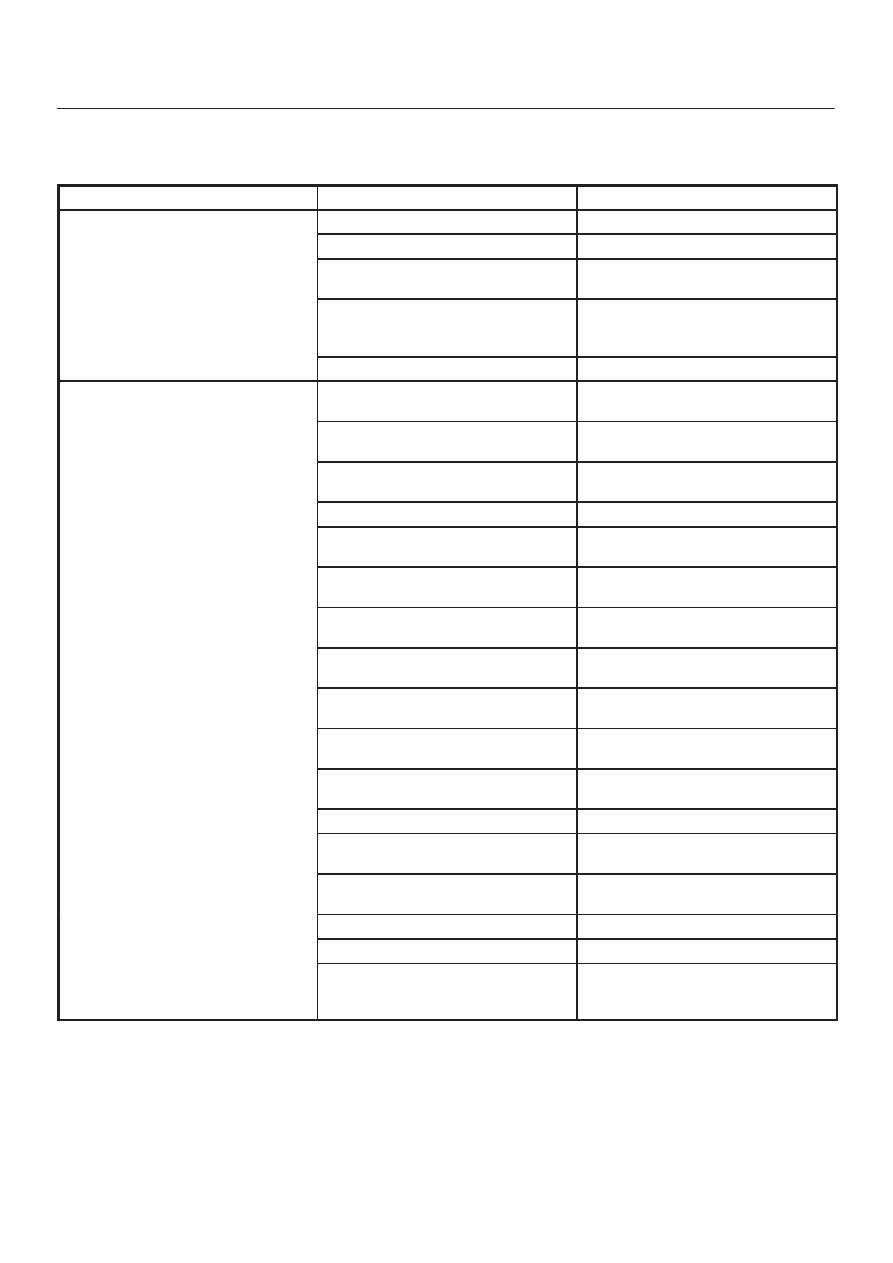

Malfunction Indicator Lamp

The instrument panel “CHECK ENGINE” Malfunction In-

dicator Lamp (MIL) illuminates by self diagnostic system

when the system checks the starting of engine, or senses

malfunctions.

Condition

Possible cause

Correction

“CHECK ENGINE” MIL does not

illuminate at the starting of engine

Bulb defective

Replace

illuminate at the starting of engine

MIL circuit open

Correct or replace

Command signal circuit to operate

self diagnostic system shorted

Correct or replace

Engine Control Module (ECM) cable

loosely connected, disconnected or

defective

Correct or replace

ECM defective

Replace

“CHECK ENGINE” MIL illuminates,

and stays on

Deterioration of heated oxygen

sensor internal element

Replace

Heated oxygen sensor connector

terminal improper contact

Reconnect properly

Heated oxygen sensor lead wire

shorted

Correct

Heated oxygen sensor circuit open

Correct or replace

Deterioration of engine coolant

temperature sensor internal element

Replace

Engine coolant temperature sensor

connector terminal improper contact

Reconnect properly

Engine coolant temperature sensor

lead wire shorted

Correct

Engine coolant temperature sensor

circuit open

Correct or replace

Throttle position sensor open or

shorted circuits

Correct or replace

Deterioration of crankshaft position

sensor

Replace

Crankshaft position sensor circuit

open or shorted

Correct or replace

Vehicle speed sensor circuit open

Correct or replace

Manifold absolute pressure sensor

circuit open or shorted

Correct or replace

Intake air temperature sensor circuit

open or shorted

Correct or replace

Fuel injector circuit open or shorted

Correct or replace

ECM driver transistor defective

Replace ECM

Malfunctioning of ECM RAM

(Random Access Memory) or ROM

(Read Only Memory)

Replace ECM