Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual - part 226

ENGINE DRIVEABILITY AND EMISSIONS

6E–145

6

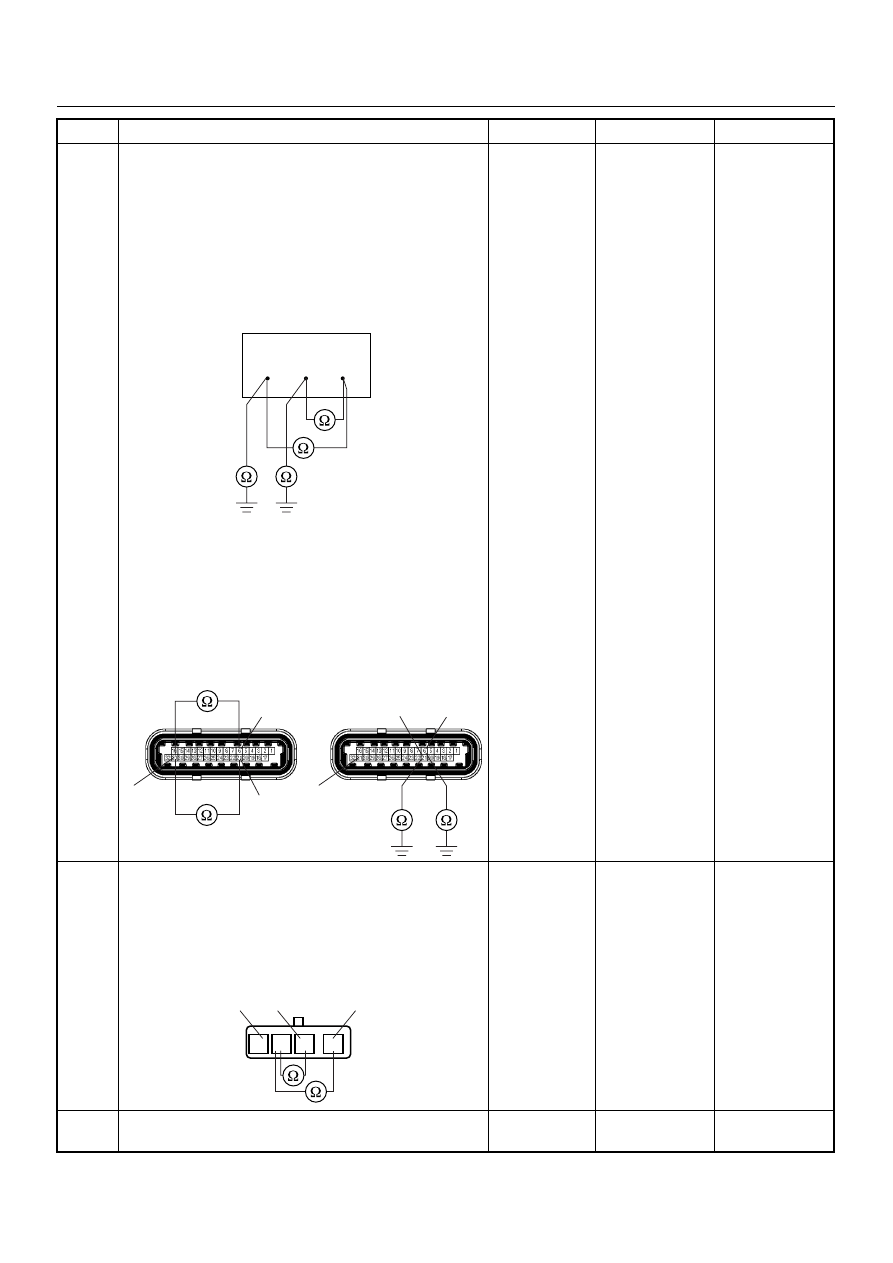

Using the DVM and check the O

2

sensor circuit.

Breaker box is available:

1. Ignition “Off”, engine “Off”.

2. Install the breaker box as type A. (ECM

disconnected) Ref. 6E-80.

3. Disconnect the O

2

sensor.

4. Check the circuit for short to heater ground or

short to ground circuit.

Was the problem found?

Breaker box is not available:

1. Ignition “Off”, engine “Off”.

2. Disconnect the O

2

sensor connector and ECM

connector.

3. Check the circuit for short to heater ground or

short to ground circuit.

Was the problem found?

—

Repair faulty

harness and

verify repair

Go to Step 15

7

Using the DVM and check the O

2

sensor circuit.

1. Ignition “Off”, engine “Off”.

2. Disconnect the the O

2

sensor connector.

3. Check the circuit for short to heater ground circuit.

Was the DVM indicated specified value?

No continuity

Go to Step 9

Go to Step 8

8

Repair the short to heater ground circuit.

Was the problem found?

—

Verify repair

Go to Step 15

Step

Action

Value(s)

Yes

No

38

53

63

31

21

6

C56(J2)

31

21

6

C56(J2)

1

2

4

1

2

3

4

O

2

Sensor