Content .. 1711 1712 1713 1714 ..

Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual - part 1713

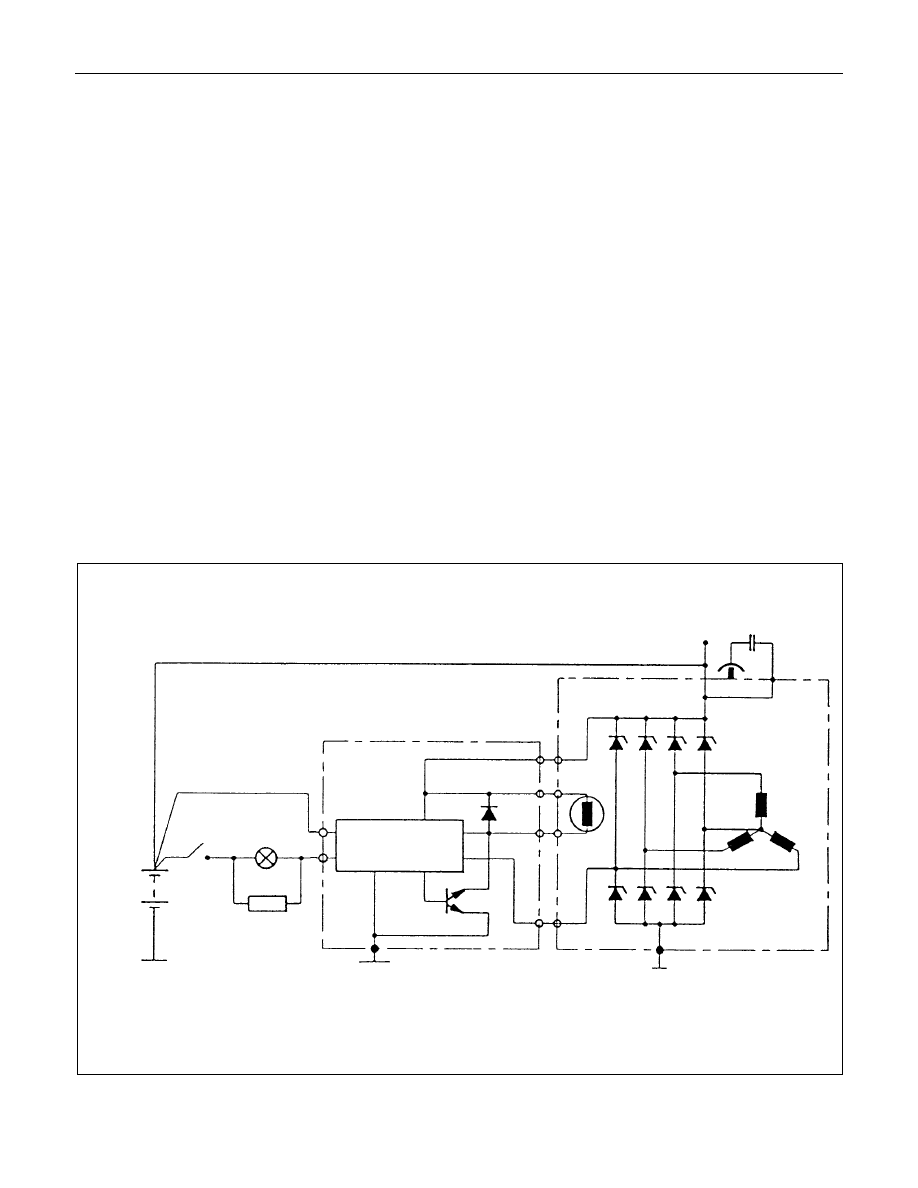

6D3-10 STARTING AND CHARGING SYSTEM

The generator has four external connections; the "B+" lead to

battery positive, "L" lead to the warning lamp circuit(max. 2

watts), "S" lead to battery positive terminal for battery sensing

and an earth connection.

Explanation of type inscripiton

Example:KC-A--> 14V 50-90A.

K

= Code for Stator OD(126mm OD).

C

= Compact Generator.

A

= Ausland (countries other than Germany)

>

= Direction of rotation(clockwise).

14V = Generator Operating Voltage.

50A = Stabilised output at 25 C at 1800 RPM./13.5

Volts.

90A = Stabilised output at 25 C at 1800 RPM./13.5

Volts.

Generator Connetions.

B+ : Battery Main Connection (battery positive)

S

: Battery Sense Connection(battery positive)

L

: Waring lamp(via warning lamp to Ignition switch)

BATT.SENSE

REGULATOR ASSEMBLY

HYBR10

ALTERNATOR ASSEMBLY

12V BATT.

1GN.SW.

300a*

WARN.LAMP

1.2 WATT

L

S

8+

SUPPRESSOR

CAPACITOR

0.5

µf

NOTE: * RESISTOR IS RECOMMENDED TO

ENSURE THAT THE GENERATOR

REMAINS FUNCTIONAL IN CASE OF

WARNING LAMP FAILURE