Content .. 1655 1656 1657 1658 ..

Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual - part 1657

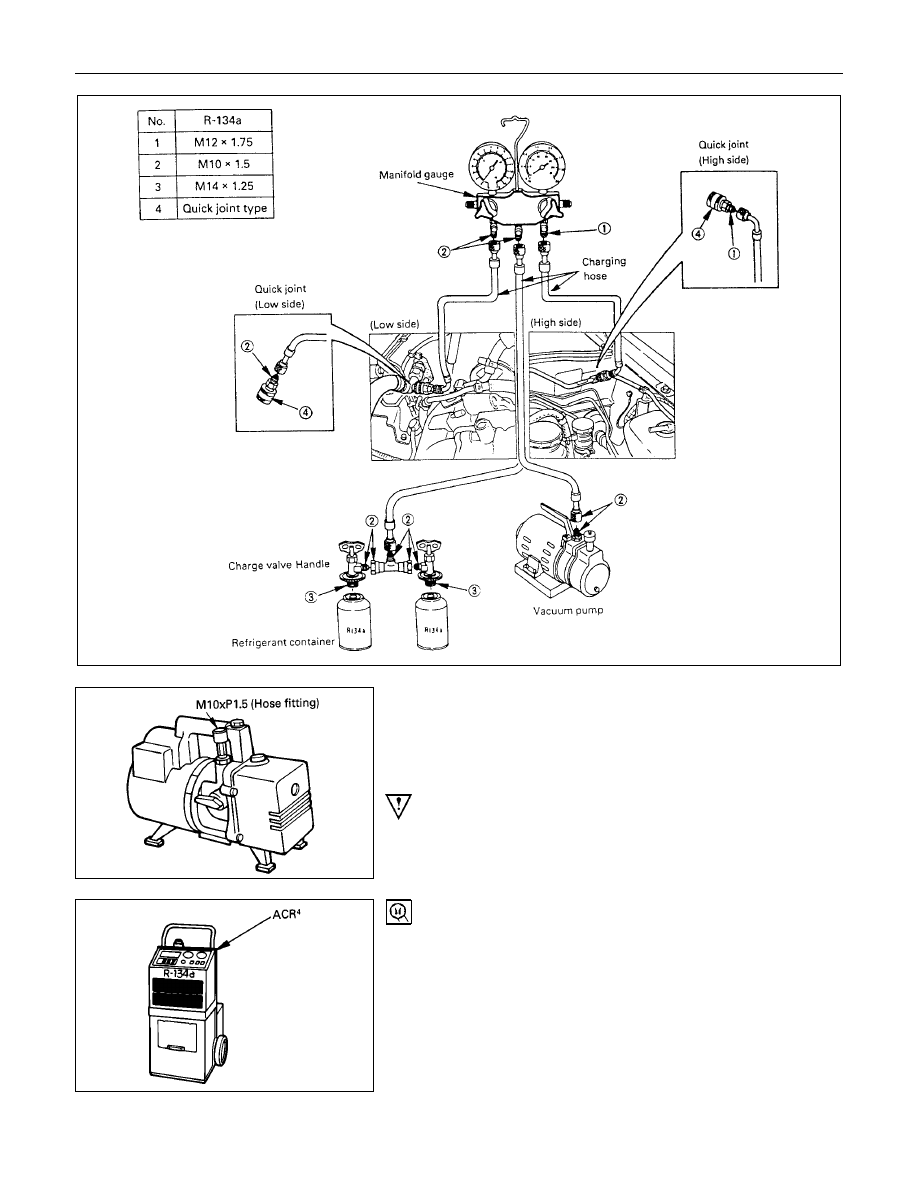

1-14 HEATING AND AIR CONDITIONING

•

Do not use the same vacuum pump for evacuating the R-

134a and R-12 systems interchangeably (The vacuum

pump hose fitting is a M10

×

1.5).

•

R-134a vacuum pumps must have a positive shutoff valve.

CAUTION

Never use the same vacuum pump for both R-134a and R-

12 systems, as cross contamination of compressor oil

may occur.

Refrigerant Recovery, Recycling and

Charging

•

R Avoid releasing the R-134a into the atmosphere.

Use the ACR

4

(R-134a Refrigerant Recovery/Recycling/

Recharging/System) or equivalent to recover and recycle R-

134a. Note that the ACR

4

(or equivalent) is not

interchangeable between the R-134a and R-12 systems.

ACR

4

(115V 60 Hz) : 5-8840-0629-0 (J-39500-A)

ACR

4

(220-240V 50/60 Hz)

: 5-8840-0630-0 (J-39500-220A)

ACR

4

(220-240V 50/60 Hz Australian model)

: 5-8840-0631-0 (J-39500-220ANZ)