Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual - part 128

6E–116

4JH1 ENGINE DRIVEABILITY AND EMISSIONS

temperature is cold, and it will be low when the engine

temperature is hot.

The output voltage excessively high or low, DTC P0115

(Symptom Code 1) or P0115 (Symptom Code 2) will be

stored.

Diagnostic Aids

An intermittent may be caused by the following:

• Poor connections.

• Misrouted harness.

• Rubbed through wire insulation.

• Broken wire inside the insulation.

Check for the following conditions:

• Poor connection at ECM-Inspect harness connectors

for backed out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal to wire connection.

• Damaged harness-Inspect the wiring harness for

damage. If the harness appears to be OK, observe

the “Coolant Temperature” display on the Tech2 while

moving connectors and wiring harness related to the

sensor.

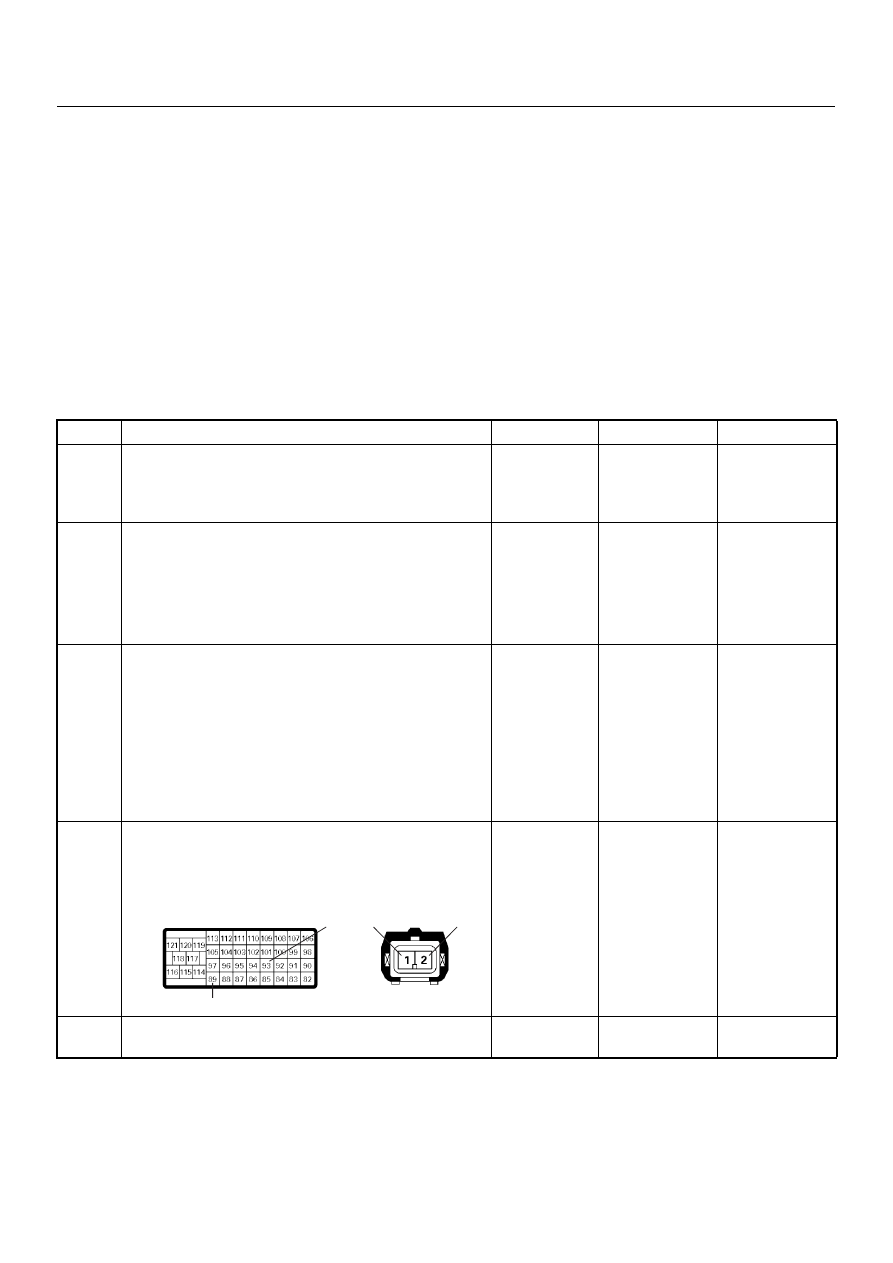

Diagnostic Trouble Code (DTC) P0115 (Symptom Code 1) (Flash Code 14)

Engine Coolant Temperature Sensor Circuit High Input

Step

Action

Value(s)

Yes

No

1

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to Step 2

Go to On Board

Diagnostic

(OBD) System

Check

2

1. Connect the Tech 2.

2. Review and record the failure information.

3. Select “F0: Read DTC Infor As Stored By ECU” in

“F0: Diagnostic Trouble Codes”.

Is the DTC P0115 (Symptom Code 1) stored as

“Present Failure”?

—

Go to Step 3

Refer to

Diagnostic Aids

and Go to Step

3

3

1. Using the Tech 2, ignition “On” and engine “Off”.

2. Select “F1: Clear DTC Information” in “F0:

Diagnostic Trouble Codes” with the Tech 2 and

clear the DTC information.

3. Operate the vehicle and monitor the “F0: Read

DTC Infor As Stored By ECU” in the “F0:

Diagnostic Trouble Codes”.

Was the DTC P0115 (Symptom Code 1) stored in this

ignition cycle?

—

Go to Step 4

Refer to

Diagnostic Aids

and Go to Step

4

4

Check for poor/faulty connection at the ECT sensor or

ECM connector. If a poor/faulty connection is found,

repair as necessary.

Was the problem found?

—

Verify repair

Go to Step 5

5

Visually check the ECT sensor.

Was the problem found?

—

Go to Step 12

Go to Step 6

93

2

1

89

E-41

C-57(B)