Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual - part 118

6E–76

4JH1 ENGINE DRIVEABILITY AND EMISSIONS

6. The Tech2 parameters which is not within the typical

range may help to isolate the area which is causing the

problem.

12. This vehicle is equipped with ECM which utilizes an

electrically erasable programmable read only memory

(EEPROM).

On-Board Diagnostic (OBD) System Check

Step

Action

Value(s)

Yes

No

1

1. Ignition “On”, engine “Off”.

2. Check the “CHECK ENGINE” lamp (MIL).

Does the “CHECK ENGINE” lamp turn “On”?

—

Go to Step 2

Go to No

CHECK

ENGINE Lamp

2

1. Using the Tech 2, ignition “On” and engine “Off”.

2. Attempt to display “Data Display” with the Tech 2.

Does the Tech 2 display engine data?

—

Go to Step 3

Go to Step 7

3

1. Using the Tech 2, ignition “On” and engine “Off”.

2. Select the “Miscellaneous Test” and perform the

“Check Light” in “Lamps”.

3. Operate the Tech 2 in accordance with the Tech 2

instructions.

Does the “CHECK ENGINE” lamp turn “Off”?

—

Go to Step 4

Go to CHECK

ENGINE LAMP

On Steady

4

Attempt to start the engine.

Does the engine start and continue to “Run”?

—

Go to Step 5

Go to Engine

Cranks But Will

Not Run

5

1. Using the Tech 2, ignition “On” and engine “Off”.

2. Select the “Read DTC Infor As Stored By ECU” in

“Diagnostic Trouble Code”.

3. Are any DTCs stored?

—

Go to DTC

Chart

Go to Step 6

6

Compare typical scan data values displayed on the

Tech 2 “Data Display”.

Are the displayed values within the range?

—

Refer to

SYMPTOM

DIAGNOSIS

Refer to

TYPICAL

SCAN DATA

7

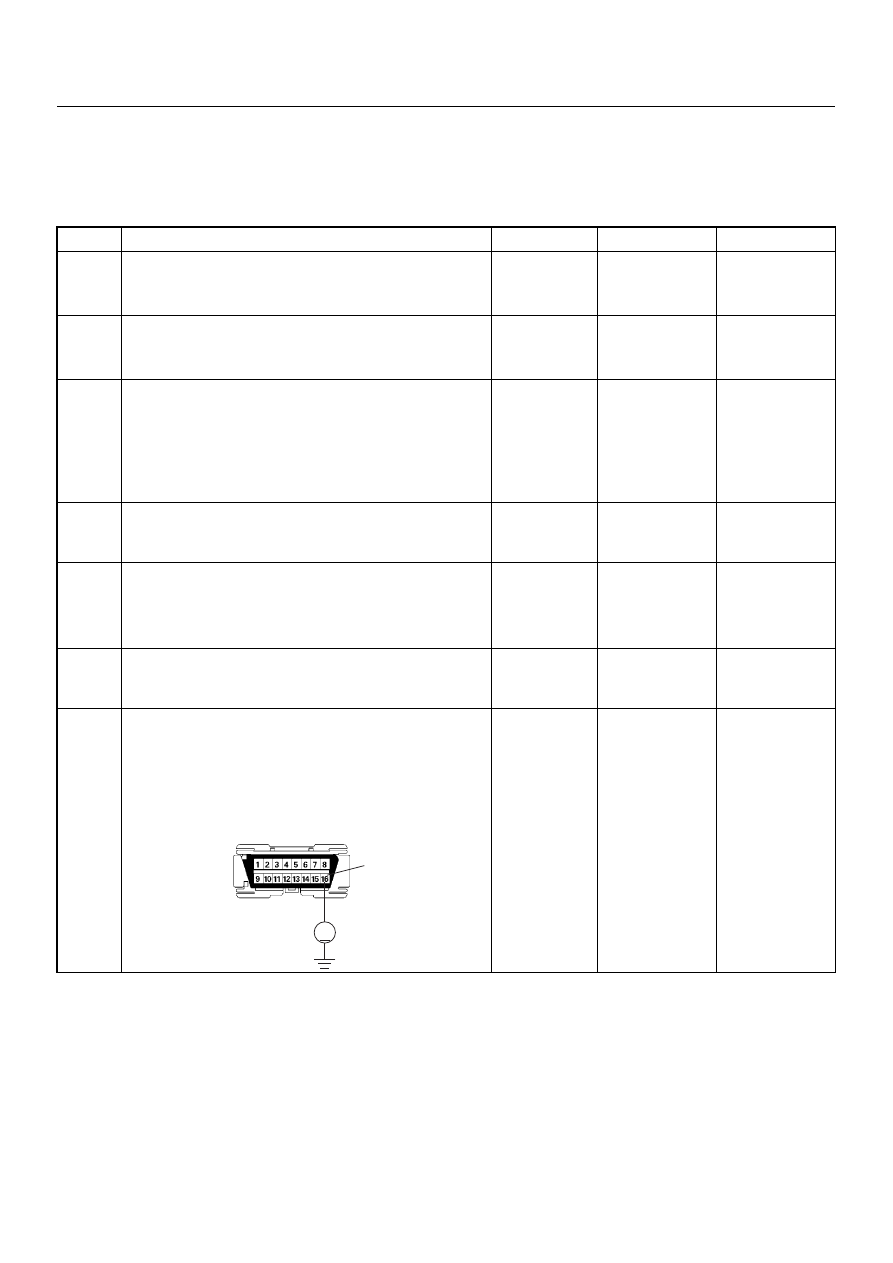

Using the DVM and check the data link connector

power supply circuit.

1. Ignition “Off”, engine “Off”.

2. Check the circuit for open circuit.

Was the problem found?

—

Repair faulty

harness and

verify repair

Go to Step 8

V

16

B-58