Infiniti G35 (V35) Sedan. Manual - part 913

ENGINE MAINTENANCE

MA-17

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

B

MA

N

O

A

2.

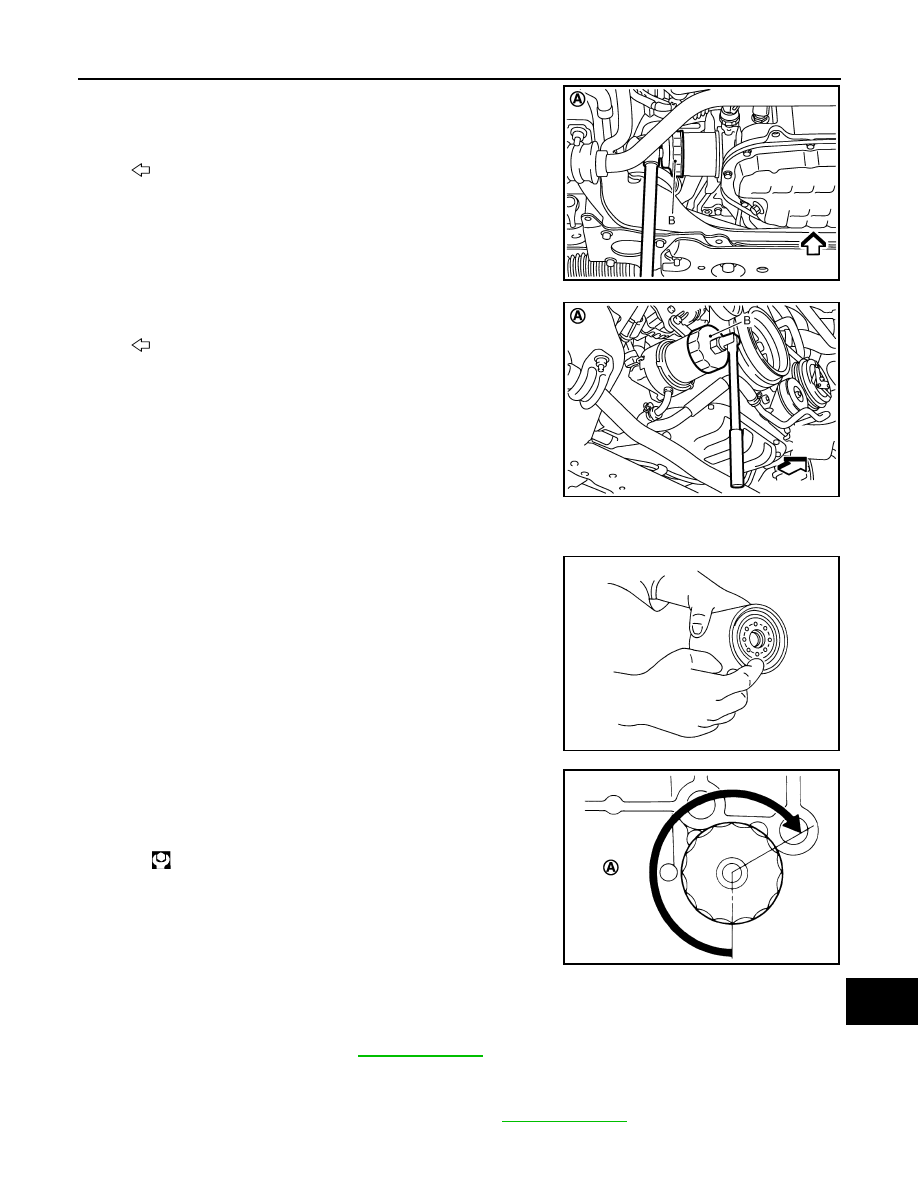

Using oil filter wrench [SST: KV10115801 (J38956)] (B), remove

oil filter.

INSTALLATION

1.

Remove foreign materials adhering to oil filter installation surface.

2.

Apply engine oil to the oil seal contact surface of new oil filter.

3.

Screw oil filter manually until it touches the installation surface,

then tighten it by 2/3 turn (A). Or tighten to the specification.

OIL FILTER : Inspection

INFOID:0000000000967312

INSPECTION AFTER INSTALLATION

1.

Check the engine oil level. Refer to

.

2.

Start the engine, and check there is no leak of engine oil.

3.

Stop the engine and wait for 10 minutes.

4.

Check the engine oil level, and adjust the level. Refer to

.

A

: 2WD

: Engine front

JPBIA0252GB

A

: AWD

: Engine front

JPBIA0076ZZ

SMA010

Oil filter:

: 17.7 N·m (1.8 kg-m, 13 ft-lb)

JPBIA0077ZZ