Infiniti G35 (V35). Manual - part 520

PRECAUTIONS

GI-5

C

D

E

F

G

H

I

J

K

L

M

B

GI

Precautions for Battery Service

NAS0001B

Before disconnecting the battery, lower both the driver and passenger windows. This will prevent any interfer-

ence between the window edge and the vehicle when the door is opened/closed. During normal operation, the

window slightly raises and lowers automatically to prevent any window to vehicle interference. The automatic

window function will not work with the battery disconnected.

General Precautions

NAS0001C

●

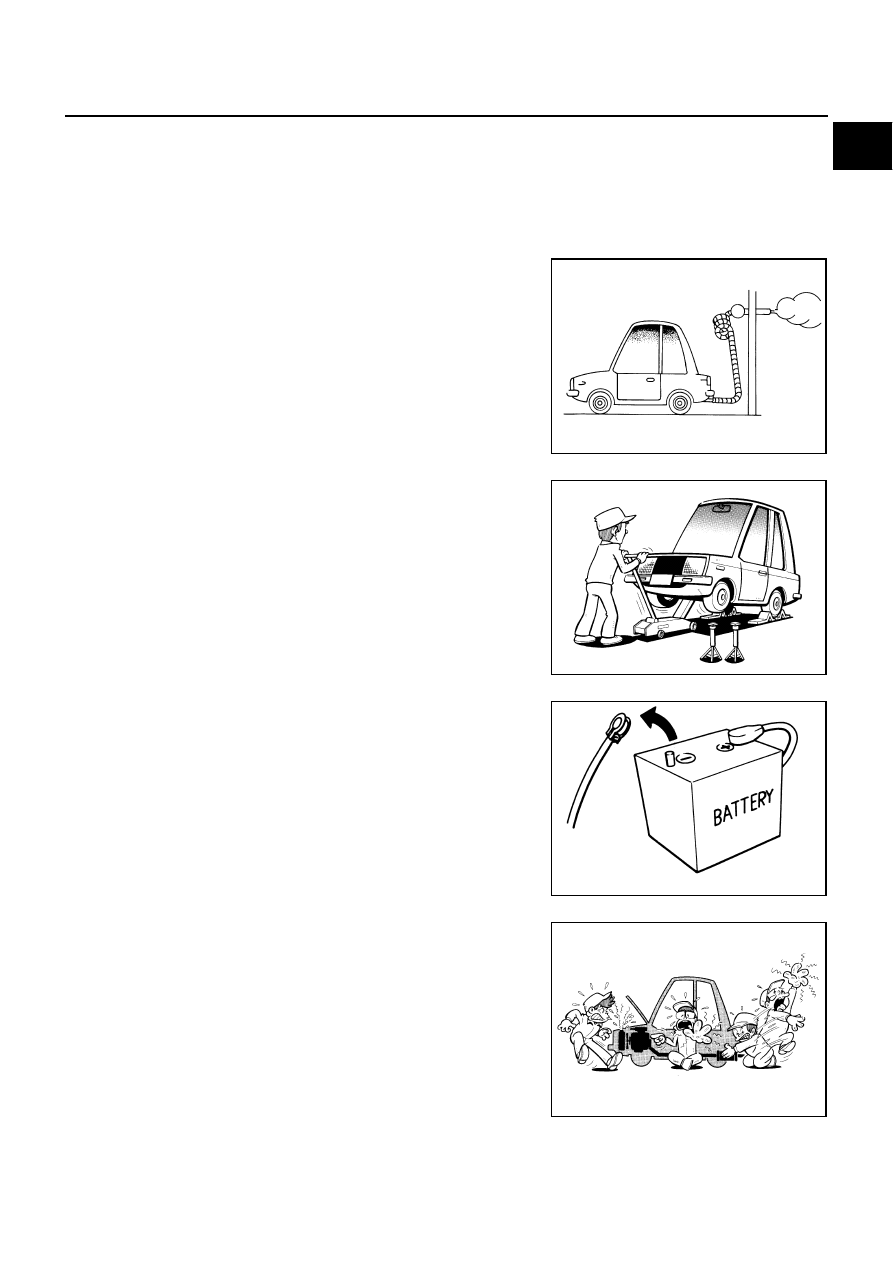

Do not operate the engine for an extended period of time without

proper exhaust ventilation.

Keep the work area well ventilated and free of any flammable

materials. Special care should be taken when handling any flam-

mable or poisonous materials, such as gasoline, refrigerant gas,

etc. When working in a pit or other enclosed area, be sure to

properly ventilate the area before working with hazardous mate-

rials.

Do not smoke while working on the vehicle.

●

Before jacking up the vehicle, apply wheel chocks or other tire

blocks to the wheels to prevent the vehicle from moving. After

jacking up the vehicle, support the vehicle weight with safety

stands at the points designated for proper lifting before working

on the vehicle.

These operations should be done on a level surface.

●

When removing a heavy component such as the engine or tran-

saxle/transmission, be careful not to lose your balance and drop

them. Also, do not allow them to strike adjacent parts, especially

the brake tubes and master cylinder.

●

Before starting repairs which do not require battery power:

Turn off ignition switch.

Disconnect the negative battery terminal.

●

If the battery terminals are disconnected, recorded memory of

radio and each control unit is erased.

●

Battery posts, terminals and related accessories contain lead

and lead compounds. Wash hands after handling.

●

To prevent serious burns:

Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

●

Dispose of or recycle drained oil or the solvent used for cleaning

parts in an appropriate manner.

●

Do not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel

spray and possibly a fire.

●

Clean all disassembled parts in the designated liquid or solvent

prior to inspection or assembly.

●

Replace oil seals, gaskets, packings, O-rings, locking washers, cotter pins, self-locking nuts, etc. with new

ones.

●

Replace inner and outer races of tapered roller bearings and needle bearings as a set.

SGI285

SGI231

SEF289H

SGI233