Infiniti G35 (V35). Manual - part 248

TROUBLE DIAGNOSIS FOR SYSTEM

BRC-53

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

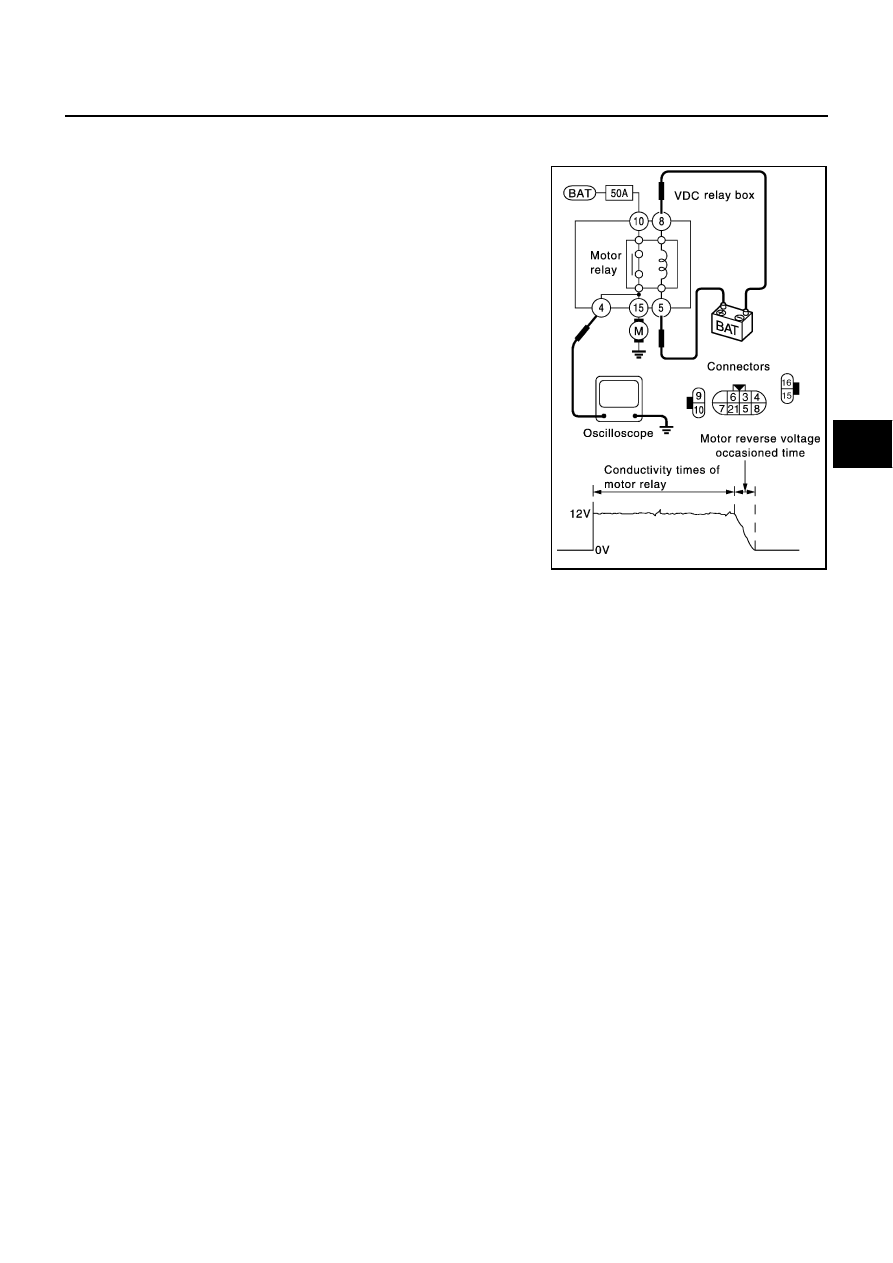

VDC/TCS/ABS ACTUATOR

Actuator Operation Inspection

1.

Turn ignition switch OFF, apply a voltage of 12 V between VDC

relay box connector E47 terminal 5 and 8, use an oscilloscope

to measure motor voltage at this time (between terminal 4 and

ground), and check motor reverse voltage occurrence time

when operation is stopped.

CAUTION:

●

Above check should be performed after motor relay unit

inspection to make sure relay operates normally.

●

To prevent overheating, do not drive actuator motor more

than 4 seconds.

●

Motor reverse voltage occurrence time is standard when

battery voltage is 12 V and the air temperature is 20

°

C

(68

°

F), and this time is a little shorter when battery voltage

is low or the air temperature is low.

Motor reverse voltage occurrence time:

0.1 second or more

SFIA0690E