Infiniti G35 (V35). Manual - part 243

TROUBLE DIAGNOSIS

BRC-33

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

Basic Inspection

NFS00070

BRAKE FLUID LEVEL AND LEAK INSPECTION

1.

Check fluid level in brake reservoir tank. If fluid level is low, refill brake fluid.

2.

Check for leakage in brake piping and around VDC actuator. If leakage or is found, check as follows.

●

If the connections at VDC actuator connector are loose, tighten piping to specified torque. Then inspect

again and confirm that there is no leakage.

●

If flare nuts or screws of VDC actuator are damaged and loose, replace damaged parts. Then inspect

again and confirm that there is no leakage.

●

If there is leakage at any location other than VDC actuator connections, wipe away leakage with clean

cloth. Then inspect again and confirm that there is no leakage.

●

If there is leakage from VDC actuator, wipe away leakage with clean cloth. Then inspect again. If there

is leakage, replace VDC actuator.

CAUTION:

VDC actuator body cannot be disassembled.

3.

Check brake disc rotor and pads. Refer to

(rear disc brake).

INSPECTION FOR LOOSENESS OF POWER SYSTEM TERMINALS

Check battery for looseness on battery positive/negative terminals and ground connection. If looseness is

detected, fasten the connections to the specified torque. Make sure battery voltage does not drop and alterna-

tor is normal.

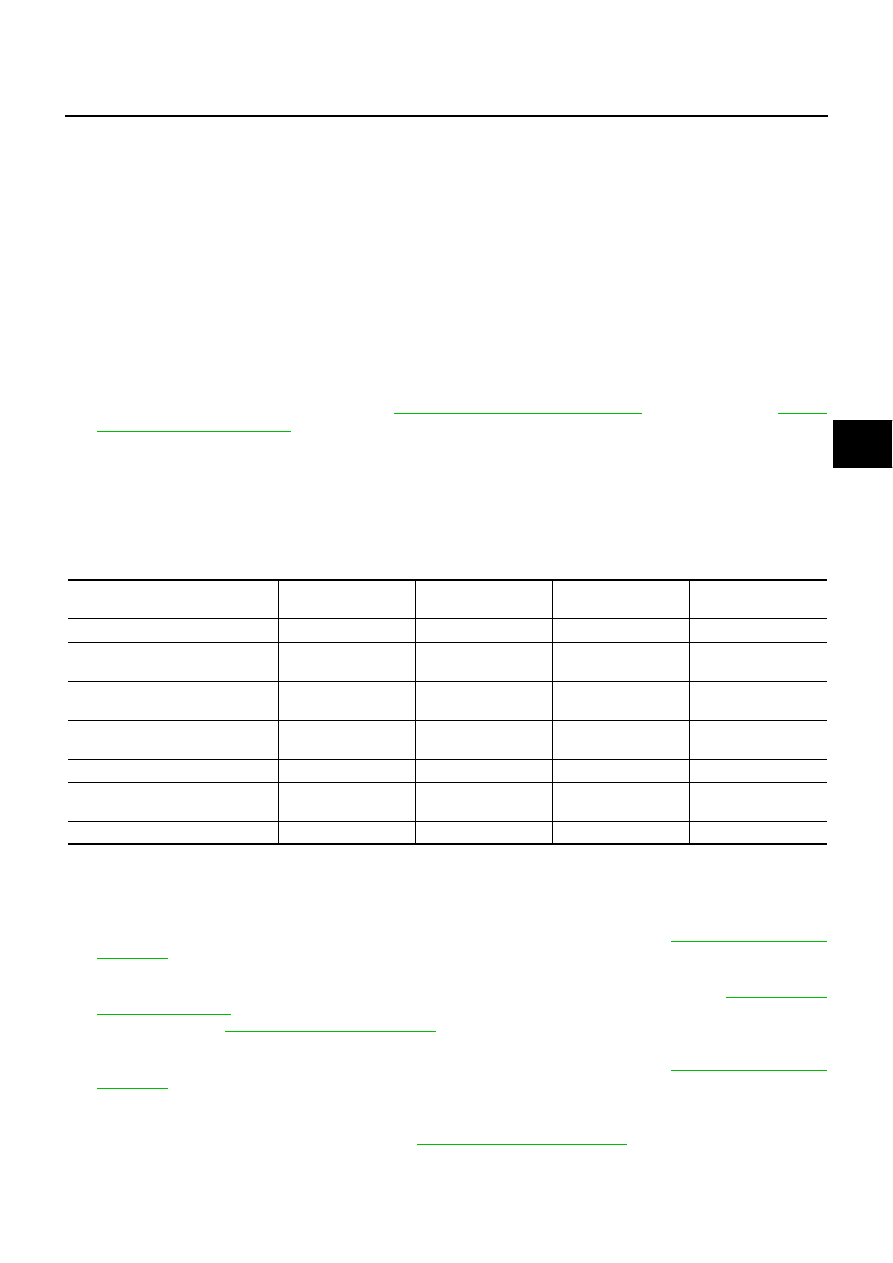

INSPECTION OF ABS WARNING LAMP, VDC OFF INDICATOR LAMP, SLIP INDICATOR LAMP

AND BRAKE WARNING LAMP

×

: ON

–: OFF

Note1:Brake warning lamp will turn on in case of parking brake operation (when switch is ON) or of brake fluid level switch operation

(when brake fluid is insufficient).

Note2:After starting engine, brake warning lamp is turned off.

1.

Make sure that ABS warning lamp illuminates when ignition switch is turned ON. If it does not illuminate,

inspect ABS warning lamp and circuit, and inspect combination meter. Refer to

.

2.

Make sure that VDC OFF indicator lamp illuminates when ignition switch is turned ON. If it does not illumi-

nate, inspect VDC OFF indicator lamp and circuit, and inspect combination meter. Refer to

. If VDC OFF indicator lamp does not illuminate, inspect VDC OFF switch and circuit

3.

Make sure that SLIP indicator lamp illuminates when ignition switch is turned ON. If it does not turn on,

check SLIP indicator lamp and circuit, and inspect combination meter. Refer to

.

4.

With engine running, turn VDC OFF switch ON and OFF. Check that VDC OFF indicator lamp turns ON

and OFF. If indicator lamp does not turn ON and OFF in accordance with switch over of VDC OFF switch,

inspect VDC OFF switch and circuit. Refer to

.

Condition

ABS warning lamp

VDC OFF

indicator lamp

SLIP indicator lamp

Brake warning lamp

[Note1]

Ignition switch OFF

–

–

–

–

For 1 second after turning ON igni-

tion switch

×

×

×

×

[Note 2]

1 second later after turning ON

ignition switch

–

–

–

×

[Note 2]

VDC OFF switch turned ON.

(VDC function is OFF.)

–

×

–

–

VDC/TCS/ABS error.

×

×

×

–

When VDC/TCS is not functioning

normally.

–

×

×

–

EBD error.

×

×

×

–