Hummer H2. Manual - part 64

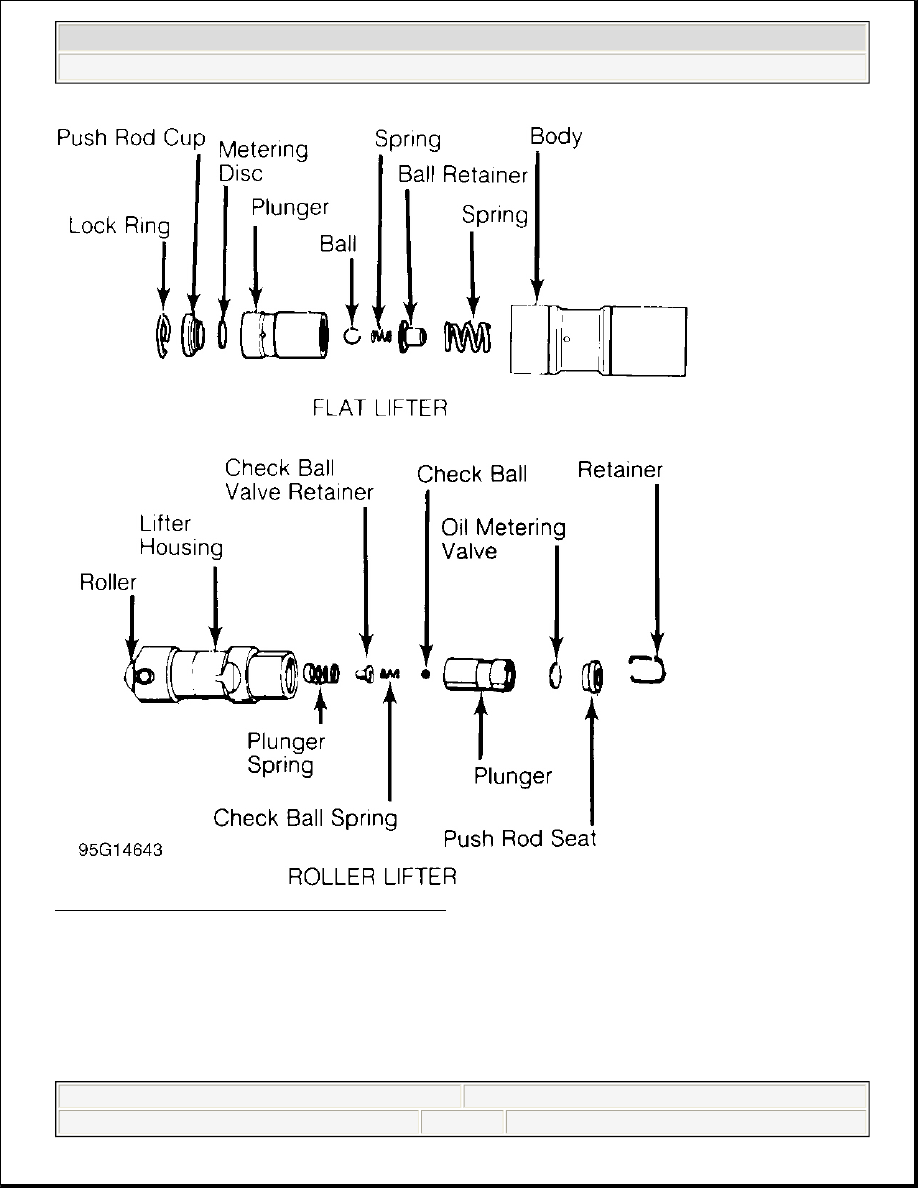

Fig. 13: Typical Hydraulic Valve Lifter Assemblies

Mechanical Lifters

Lifter assemblies must be installed in original locations. Remove rocker arm assembly and push rod. Mark

components for location. Some applications require intake manifold or lifter cover removal. Remove lifter

retainer plate (if used). To remove lifters, use lifter remover or magnet.

Inspect push rod contact area and lifter body for scoring or signs of wear. If body is scored, inspect lifter bore

1998 Chevrolet Pickup C1500

GENERAL INFORMATION Engine Overhaul Procedures