Hummer H1 (2002+). Manual - part 32

____________________________________________________________________

Engine 2-89

®

05745159

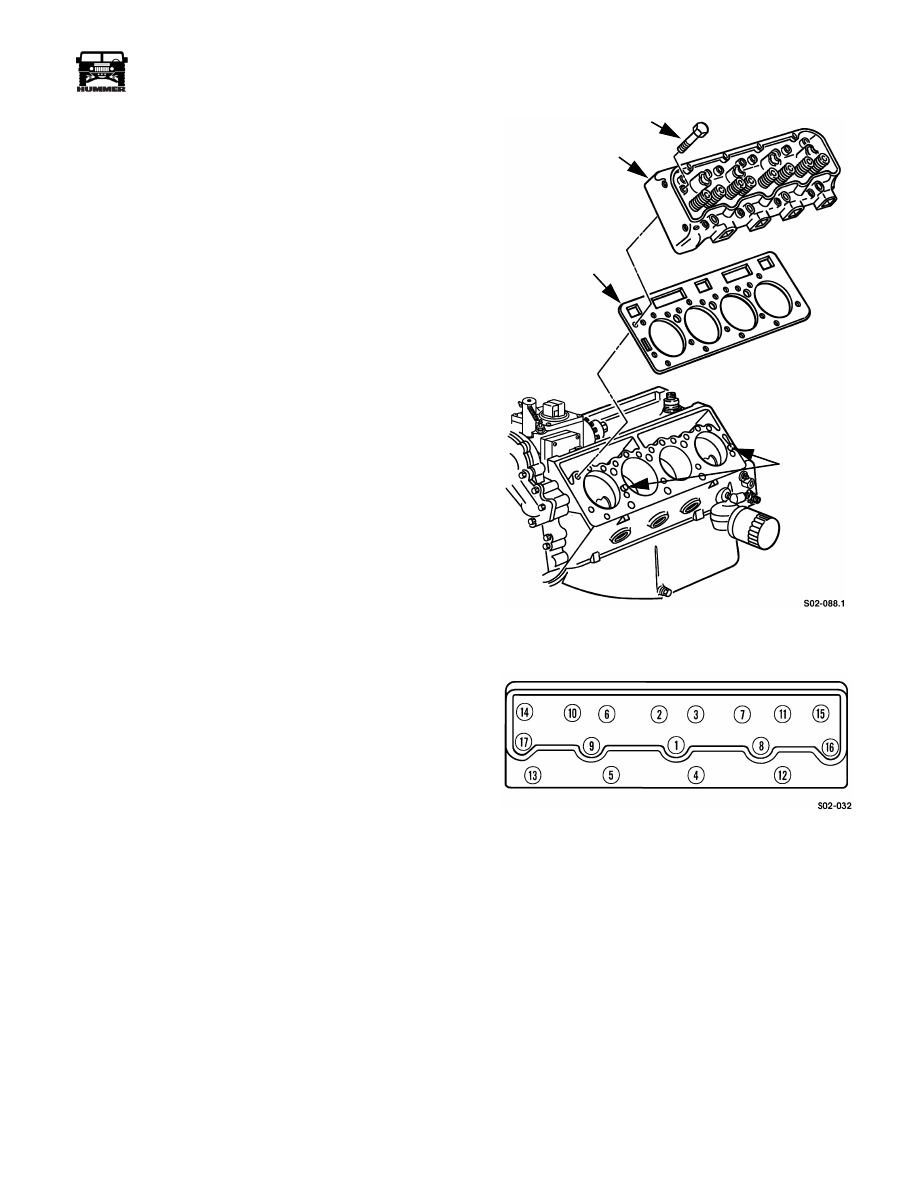

CYLINDER HEAD INSTALLATION

Important:

• Make sure that the block and head gasket surfaces are

clean.

• The head gasket material is soft. Handle the gasket with

care and make sure the gasket surface is not creased or

dented.

CAUTION: Do not apply any type of sealant to the head gas-

kets. The head gasket is made with sealant on the gasket sur-

face. Additional sealer may cause leakage and engine damage.

1.

Place each head gasket on block deck and dowels

(Figure 2-176).

2.

Carefully position each cylinder head on gasket and on

dowels (Figure 2-176).

CAUTION: Follow torque sequence for head bolts. This is

necessary for correct compression of head gasket. Failure to

do so will cause leaks.

NOTE: Use the correct fastener in the correct location. Do not

use paints, lubricants, or corrosion inhibitors on fasteners or

fastener joint surfaces unless specified. These coatings affect

torque and joint clamping force and may damage the fastener.

Use the correct tightening sequence and specifications when

installing fasteners in order to avoid damage to parts and sys-

tems.

3.

Install cylinder head bolts as follows:

a.

Apply Loctite 592 pipe thread sealant to bolt threads

and under bolt heads.

b.

Tighten bolts in sequence (Figure 2-177), to 20 lb-ft

(25 N•m) torque.

c.

Repeat bolt tightening sequence to a torque of 55 lb-ft

(75 N•m).

d.

Retighten bolts in sequence to 55 lb-ft (75 N•m).

e.

Tighten bolts an additional 90-100 degrees (1/4 plus

turn).

Figure 2-176: Cylinder Head and Gasket

Installation

Figure 2-177: Cylinder Head Bolt Tightening

Sequence

CYLINDER HEAD

GASKET

DOWELS

HEAD

HEAD BOLT